Caution – Cashco Ranger QCT User Manual

Page 13

IOM-Ranger

13

H. Slurry Trim – Opt-AS:

1. Install the trim in the body (1) per Section IV,

Sub sec tion C, Articles 1 through 10.

2. Slide retainer sleeve subassembly (8) onto

the stem assembly (7) with the stem retainer

carbon bushing (8.2) end against the stem

(7) subassembly shoulder.

3. Apply lubricant (silicon grease or equiv a lent)

to O-ring (30), and slide backup ring (31) and

O-ring (30), re spec tive ly, into groove on stem

(7) groove-end. See Figure 21 for O-ring (30)

orientation.

4. Insert the stem/retainer sleeve (7)(8) as sem-

bly into the body (1), aligning the hole in the

retainer sleeve (8) to be directly in line with

the thread ed hole in the body (1) bonnet.

Align the stem sub as sem bly (7) so that the

plug’s (6) tongue and the stem's (7) groove

will engage. Insert as sem bly.

NOTE: A small "fl at" area has been milled on the

stem and for correct engagement this "fl at" must

be on the same side as the face of the plug (6).

5. Visually

confi rm alignment of hole in re tain er

sleeve (8.1) with threaded hole in body (1)

bonnet. Insert and tighten stem re tain er screw

(17).

6. Rotate stem (7) to ensure tongue and groove

engagement with plug (6).

7. Proceed to Section IV, Subsection G. for

in stal la tion of packing (13).

J. Pressure

Test:

1. Cashco recommends that a pressure integrity

test be performed following reassembly when

the pack ing set (13) has been replaced.

CAUTION

b. Draw down each packing nut (22) in

al ter nat ing 1/2 revolution increments,

check ing each spacer ring (29) after each

tight en ing. When spacer ring (29) can no

long er be rotated freely by fi ngers, make

an ad di tion al 1/2 revolution – no further

tight en ing should occur to main tain the

“live-loaded” intent of the design. Over-

tight en ing of the design as de scribed

caus es the mechanism to func tion as

a “jammed pack ing. This will de feat the

design intent of the mech a nism and will

increase packing (13) wear.

c. Refer to Actuator Maintenance Man u als

IOM-48 or 148 to reconnect ac tu a tor/arm

housing (AA) to yoke (12).

6. Common to Opt-38J Jammed Packing

Only:

NOTE: Packing follower (15) must penetrate into

the stuffi ng box of the body (1).

a. Install nuts (22) on packing studs (21) and

fi nger tighten.

b. Refer to Actuator Maintenance Man u als

IOM-48 or 148 to reconnect ac tu a tor/arm

housing (AA) to yoke (12).

c. Tighten packing nuts (22) to torque levels

indicated in Table 5.

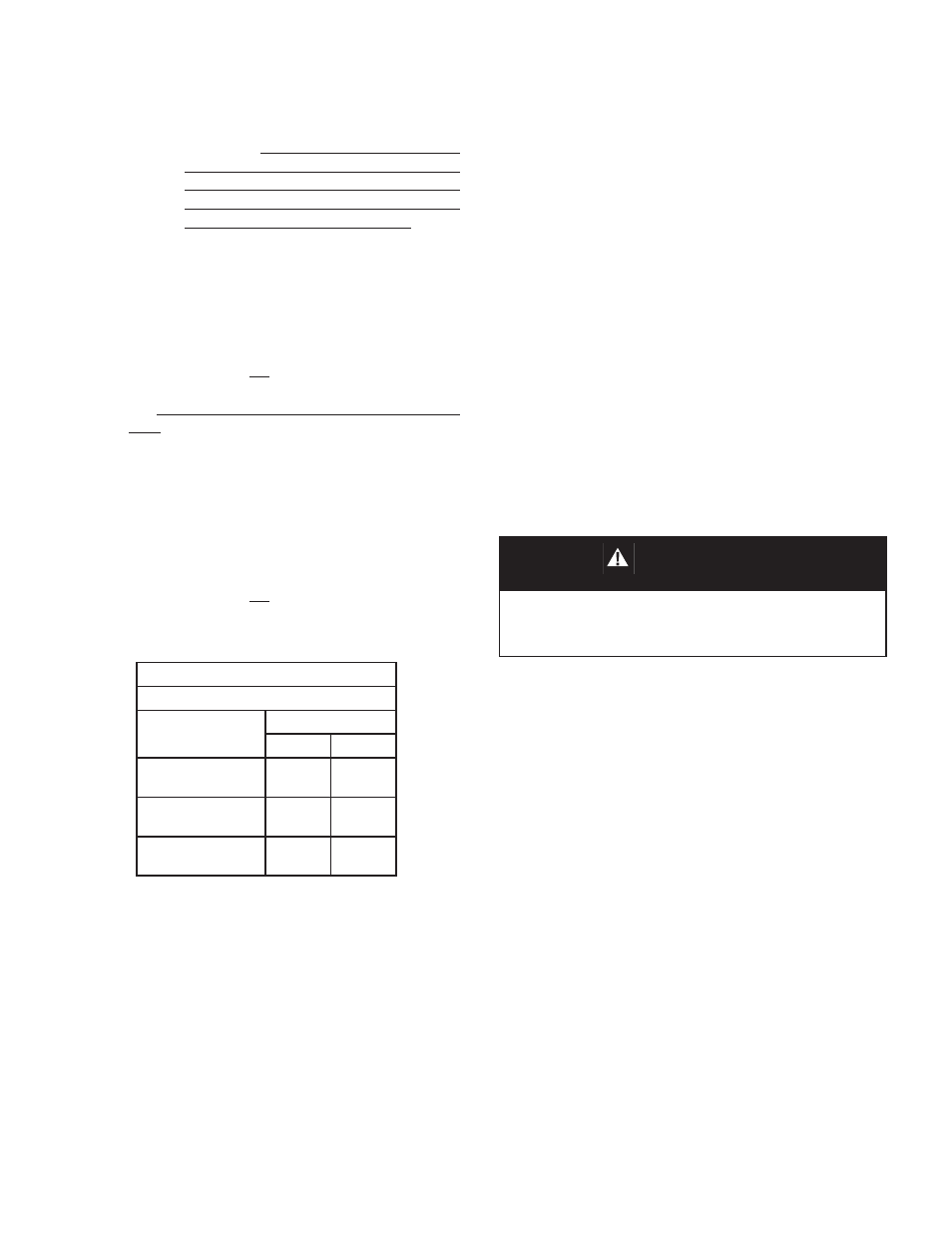

Table 5

Packing Nut Torques

Body Size

Torque

in-lbs.

N-M

1",1-1/2", 2"

(DN25, 40, 50)

50

67

3", 4"

(DN80, 100)

130

176

6" & 8"

(DN150, 200)

165

223

NOTE: When valve is returned to operation, check

for leakage and tighten the nuts (22) evenly in

alternating 1/4 revolution in cre ments until leak age

stops. DO NOT OVERTIGHTEN.

If O-ring (30) on stem subassembly (7) is inserted into

the body (1) cavity and then pulled back into the bonnet,

the O-ring (30) may be damaged.