General and commercial installation checklist, Valve to tank installation instructions – Hydrotech 9500 Commercial TMI Water Softener User Manual

Page 7

Page 7

General and Commercial Installation Checklist

WATER PRESSURE:

A minimum of 25 pounds of water pressure is required for regeneration valve to operate

effectively.

ELECTRICAL FACILITIES:

A continuous 115 volt, 60 Hertz current supply is required. Make certain the current

supply is always hot and cannot be turned off with another switch.

EXISTING PLUMBING:

Condition of existing plumbing should be free from lime and iron buildup. Piping that is

built up heavily with lime and/or iron should be replaced. If piping is clogged with iron, a separate iron filter unit

should be installed ahead of the water softener.

LOCATION OF SOFTENER AND DRAIN:

The softener should be located close to a drain.

BY-PASS VALVES:

Always provide for the installation of a by-pass valve.

Valve to Tank Installation Instructions

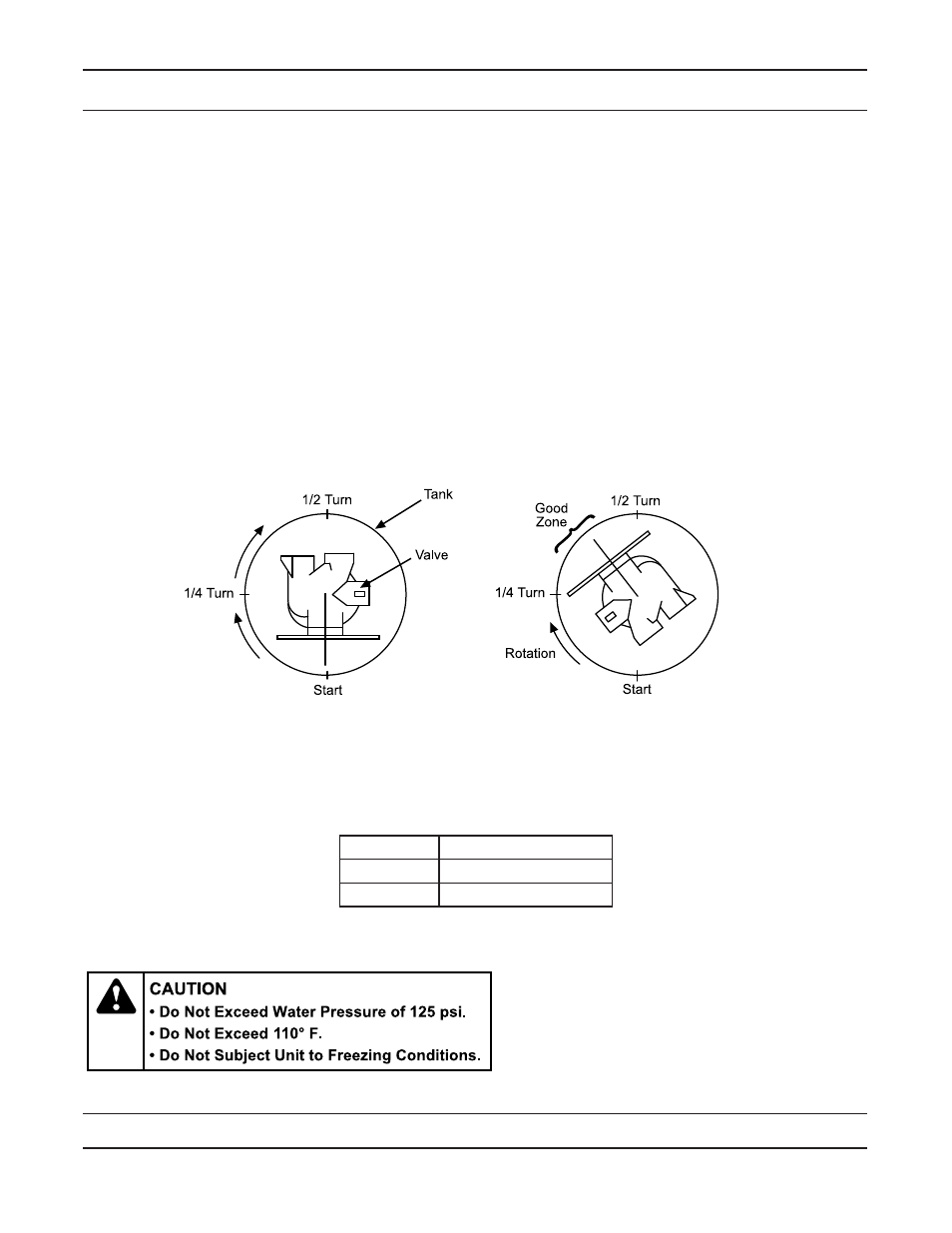

Spin the valve onto the tank, ensuring the threads are not cross-threaded..

NOTE: All Fleck

®

valves are right-hand threads, or clockwise, to install

Rotate the valve freely without using force until it comes to a stop (this position is considered zero).

Rotate the valve clockwise from zero, between ¼ turn and ½ turn (see the diagram below)..

.

1.

2.

3.

NOTE:

If lubricant is required, a silicone compound is strongly recommended. Dow Corning

®

Silicone

Compound (available from Fleck

®

), is recommended for best possible results. Dow Corning

®

7 Release

Compound is used in the manufacture of Fleck

®

control valves. The use of other types of lubricants may

attack the control’s plastic or rubber components. Petroleum-based lubricants can cause swelling in rubber

parts, including o-rings and seals. .

Part No.

Description

16174

Silicone, 2 oz Tube

16586-8

Silicone, Dow #7 8 LB