Problem cause correction – Hydrotech 2510 AIO SXT Chemical Free Iron Filter Operation Manual User Manual

Page 15

13

Section 7: Maintenance & Troubleshooting

The 2510AIO SXT Iron Filter requires annual maintenance. Please contact your dealer for maintenance kits (Part #92359).

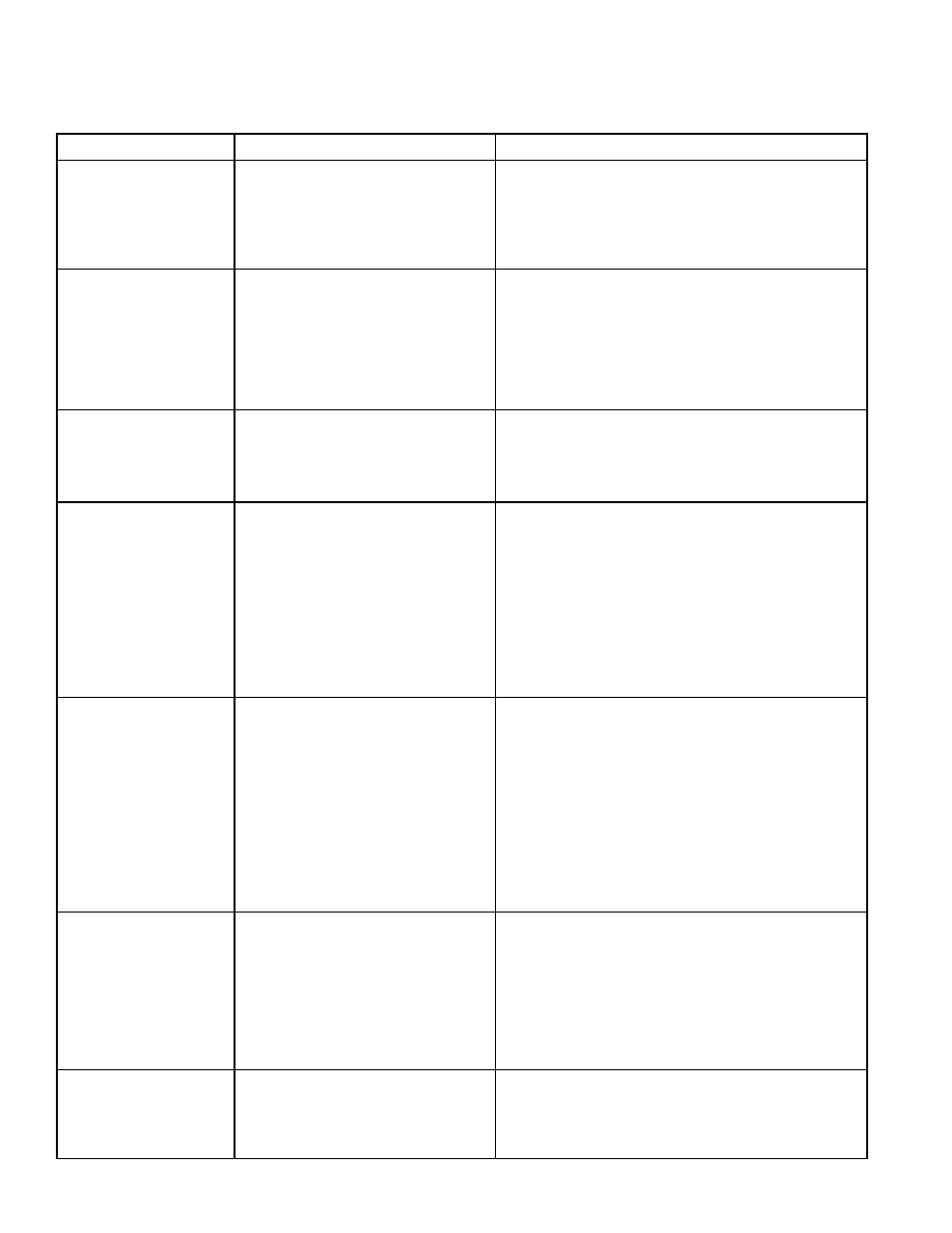

PROBLEM

CAUSE

CORRECTION

1. Unit goes does not

go through air draw

sequence

A. Electrical service to unit is

interrupted

B. Power failure

C. Timer is defective

A. i) Check supply is operating (Check fuse, plug, etc.)

ii) Check that supply cut off when light is switched

off or similar

B. Reset time of day

C. Check that dial showing days moves from day today.

If it doesn’t, replace timer

2. Unit doesn’t draw air

in refill cycle

A. Line to drain is kinked

B. Water pressure to unit is too low

C. Drain flow control is blocked

D. Injectors or screen is plugged

E. Internal leak in control

A. Straighten

B. i) Check pressure. It must be above 20psi at all

times.

ii) If below, increase pressure

C. Check and clean if necessary

D. Check and clean or replace as needed

E. Check piston and seals and spacers. Replace if

needed.

3. Water flows to drain

continuously

A. Timer motor stopped or jammed

B. Foreign material jammed inside

control

C. Internal leak

A. Replace if necessary

B. Remove piston and check

C. Inspect piston and seals and spacers. Replace if

necessary.

4. Water is clear when

drawn, turns red

upon standing (stain

producing)

A. Insufficient air drawn by valve

B. Bypass open or leaking

C. Filter bed backwashed at improper

levels

D. Presence of manganese or tannins

A. Check valve at air draw time

B. Close bypass valve and/or repair as necessary

C. Refer to backwash frequency chart in operation

manual to ensure unit is set correctly. Do not increase

the backwash frequency unless required to based

in the chart, since the media needs to be somewhat

iron-fouled for best performance (in more severe iron-

fouling cases, filter bed may need chemical cleaning

- contact dealer).

D. Recheck water analysis

5. Water is red when

drawn from tap

A. Filter bed overloaded with

precipitated iron due to insufficient

backwash flow rate.

B. Filter bed backwashed at improper

intervals

A. i) Check for obstructions or kink in drain line

ii) Check for improper drain line flow controller (see

specs). Upon correction of this problem, if manually

backwashing does not clear bed of iron, filter bed

may need chemical cleaning.

B. Refer to backwash frequency chart in operation

manual to ensure unit is set correctly. Do not

increase the backwash frequency unless required

to based on the chart, since the media needs to

be somewhat iron fouled for best performance (in

more severe iron-fouling cases, filter bed may need

chemical cleaning - contact dealer).

6. Excessive pressure

loss through filter

A. Filter bed overloaded with

precipitated iron

B. Control in/outlet valve(s) not fully

open

C. Sand, silt or mud collecting in filter

media

D. Filter bed not properly “classified”

E. “Cementing” or “channelling” of filter

media

A. Refer to Section 2

B. Open valves

C. Check well for these conditions

D. Manually backwash to reclassify.

E. Prod (stir) filter bed to break up hardened layer,

backwash frequency to prevent recurrence.

7. “Milky” or “bubbly”

water (appears

to contain small

bubbles)

A. Excess gases in water (carbon

dioxide, hydrogen sulfide, methane)

A. May require cleaning or installation or air-relief

control (contact dealer).