Maintenance of table, Maintenance of jack – Gardner Bender BE400 Eegor Bending Table User Manual

Page 4

WARRANTY: GB ELECTRICAL, INC. warrants its

products against defects in workmanship and

materials for 1 year from date of delivery to user.

Chain is not warranted. Warranty does not cover

ordinary wear and tear, abuse, misuse, overloading,

altered products or use of improper fluid.

WARRANTY RETURN PROCEDURE: When question

of warranty claim arises, send the unit to the nearest

GB Authorized Service Center for inspection,

transportation prepaid. Furnish evidence of purchase

date. If the claim comes under the terms of our

warranty the Authorized Service Center will REPAIR

OR REPLACE PARTS AFFECTED and return the unit

prepaid.

PARTS AND SERVICE: For quality workmanship and

genuine GB ELECTRICAL parts, select an Authorized

GB Service Center for your repair needs. Only

repairs performed by an Authorized Service Center

displaying the official GB Authorized sign are backed

with full factory warranty. Contact GB Electrical

(414) 352-4160 for the name of the nearest GB

Authorized Service Center.

REPAIR AND SERVICE INSTRUCTIONS: For repair service and parts contact your nearest GB ELECTRICAL

Service Center. The Service Center will provide complete and prompt service on all GB ELECTRICAL products.

GB Electrical, Inc.

An Applied Power Company

6101 N. Baker Road, Milwaukee, WI 53209

Phone: (414) 352-4160

FAX (414) 352-2377

RPS-0036 Rev. A

03/07

The table top should always be lowered

from its vertical position at a slow,

controllable rate. A freely falling table

top will only shorten the life of your

bending table and bender components.

Open the jack release valve only enough

to provide a slow smooth return of your

table top and bender to their horizontal

position. Also, when changing the table

top position from horizontal to vertical or

vertical to horizontal, always check for and

provide proper clearances for table,

bender and conduit.

Maintenance of Table

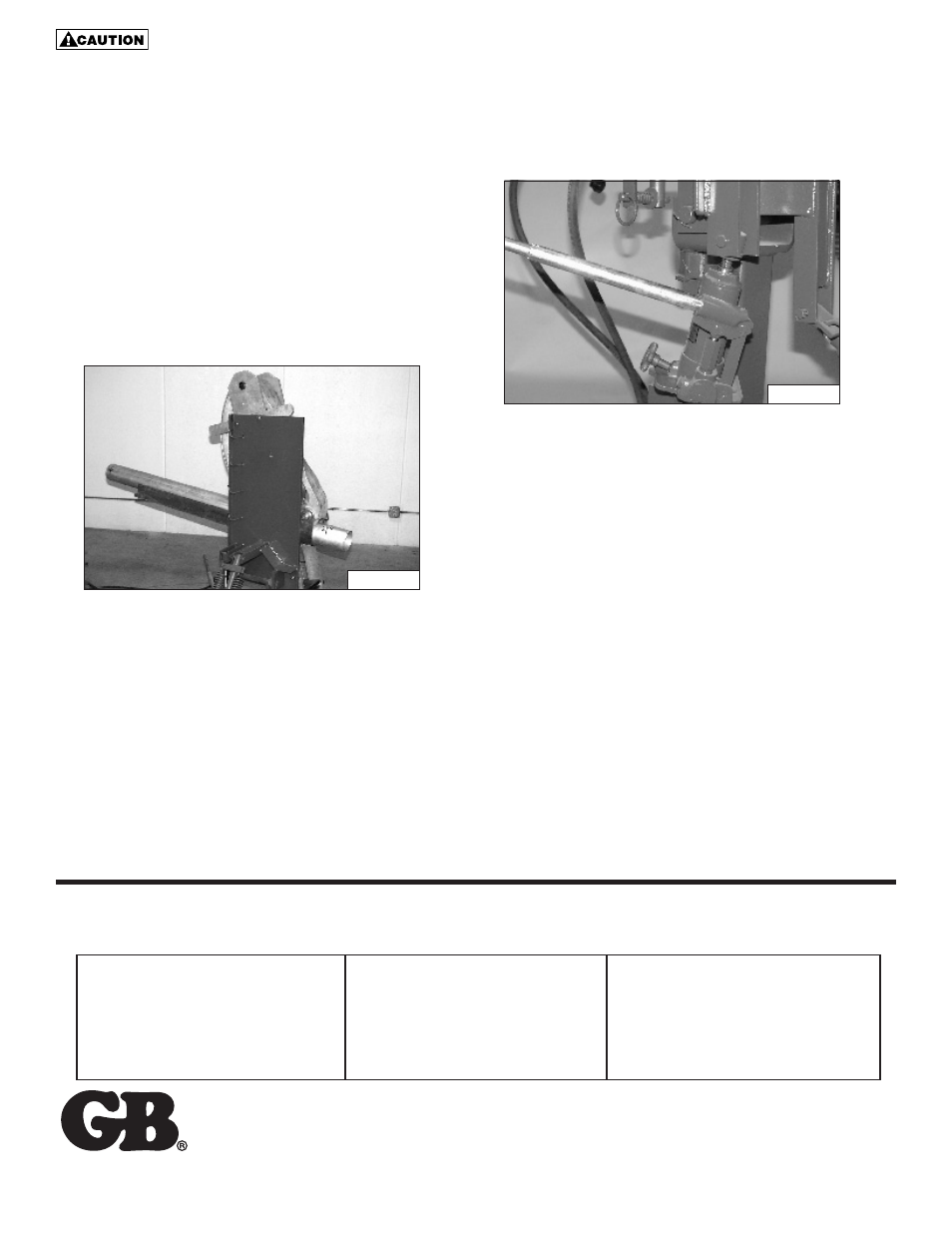

1. To lubricate, apply #20 oil to all pivot points as

indicated in Fig. 10 at least once every month.

2. Retorque the four (4) mounting screws, indicated in

Fig. 10, monthly, to 50 ft. lbs. Visually inspect all

fasteners daily and retorque where necessary.

3. Periodically inspect table for worn and/or damaged

parts and replace where necessary.

Maintenance of Jack

Filling reservoir - with table top in horizontal position,

remove the filler plug as shown in Fig. 11. Add Enerpac

Hydraulic Oil until oil level is up to filler hole. Replace

filler plug. DO NOT use brake fluid, alcohol, glycerine,

and similar fluids. These fluids will damage packings and

corrode metallic parts.

Purging air - if the oil supply is low or if the table was on

its side, the pump may have become air bound. To purge

air from the system, proceed as follows:

1. Put table top in horizontal position.

2. Remove filler plug and check oil level (do not replace

filler plug).

3. Open release valve and operate pump several times.

4. Close the release valve, operate pump and check to

see that the table top raises. If the table top does not

raise, repeat steps 3 and 4.

5. If table top does not raise, lower it to its horizontal

position. Re-check the oil level and replace filler plug.

Figure 10

Figure 11