Instruction sheet b2000 cyclone, Bender – Gardner Bender B2000 Series G-OLD Cyclone Bender User Manual

Page 3

RPS-0147

06/01

Effective for models with serial numbers beginning with "G".

Instruction Sheet

B2000 Cyclone

®

Bender

IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. If shipping damage is found, notify carrier at once. Shipping damage is NOT

covered by warranty. The carrier is responsible for all repair and replacement costs resulting from damage in shipment.

SAFETY ISSUES

IMPORTANT – USER SAFETY AND PROTECTION: In setting up systems to fit your operations, care must be taken to select the

proper components and design to insure appropriate that all safety measures have been taken to avoid the risk of personal injury

and property damage from your application or system.

GARDNER BENDER IS NOT RESPONSIBLE FOR DAMAGE OR INJURY CAUSED BY UNSAFE USE, MAINTENANCE OR THE

APPLICATION OF ITS PRODUCTS. Please contact Gardner Bender for guidance when you are in doubt as to the proper safety

precautions to be taken in designing and setting up your particular application.

1.0 DESCRIPTION

The Cyclone

®

, GB model B2000 production bender is used

to bend EMT, IMC, rigid steel or rigid aluminum conduit. A

single bending shoe accommodates sizes

1

⁄

2

",

3

⁄

4

", 1", 1

1

⁄

4

",

1

1

⁄

2

" and 2" conduit. The shoe is driven by a 115 volt, 15 amp

motor. The roller housing consists of a single urethane roller

and support arm, also three sets of nylon rollers.

The bender control pendant consists of a zero light, an

override push button and a two-position toggle switch for

“Bend and Return”. An 8-ft electrical cord connects the

pendant to the bender frame. The bender can be used in a

horizontal or vertical position.

To avoid damaging the bender control circuit, an input

voltage sensing system is built into the control circuit. If input

voltage is less than 92V AC or higher than 132V AC the

bender will shut off. One of the two lights located on the end

plate will light to indicate whether high or low voltage exists.

Re-set the bender by unplugging the power cord, and

plugging it in again. If the incoming current voltage has not

been corrected, the bender will continue to shut off. The

voltage range must be within 92V AC to 132V AC. Any

situation which causes a voltage drop or increase must be

corrected before using the B2000 Bender.

Voltage drops may be caused by:

• Extension cords that are too long.

• Extension cords made of light (16-18 gauge) wire.

• Multiple power tools on a single circuit.

• Other devices which require high amperes to operate.

2.0 WARNINGS

CAUTION: During pipe bending, stand behind the

frame handle. Keep hands, clothing and control cord away

from the bending shoe and rollers.

WARNING: Do not locate the bender on damp or wet

surfaces. Do not stand on wet surfaces while operating

the bender.

CAUTION: To prevent damage to the bending shoe,

do not allow the clamping jaws to strike the upper roller

support arm when the shoe is rotating. Position the roller

housing against the frame stop. See Figure 1.

CAUTION: Select an operating area large enough to

permit loading pipe section and bending without striking

objects or personnel.

WARNING: To avoid possible injury, do not place

fingers under the bottom edge of the bending shoe. See

Figure 2.

CAUTION: Do not attempt to bend conduit or pipe

other than

1

⁄

2

" through 2" IMC, EMT, rigid steel or

aluminum. Bending other materials will damage the

bender and void the warranty.

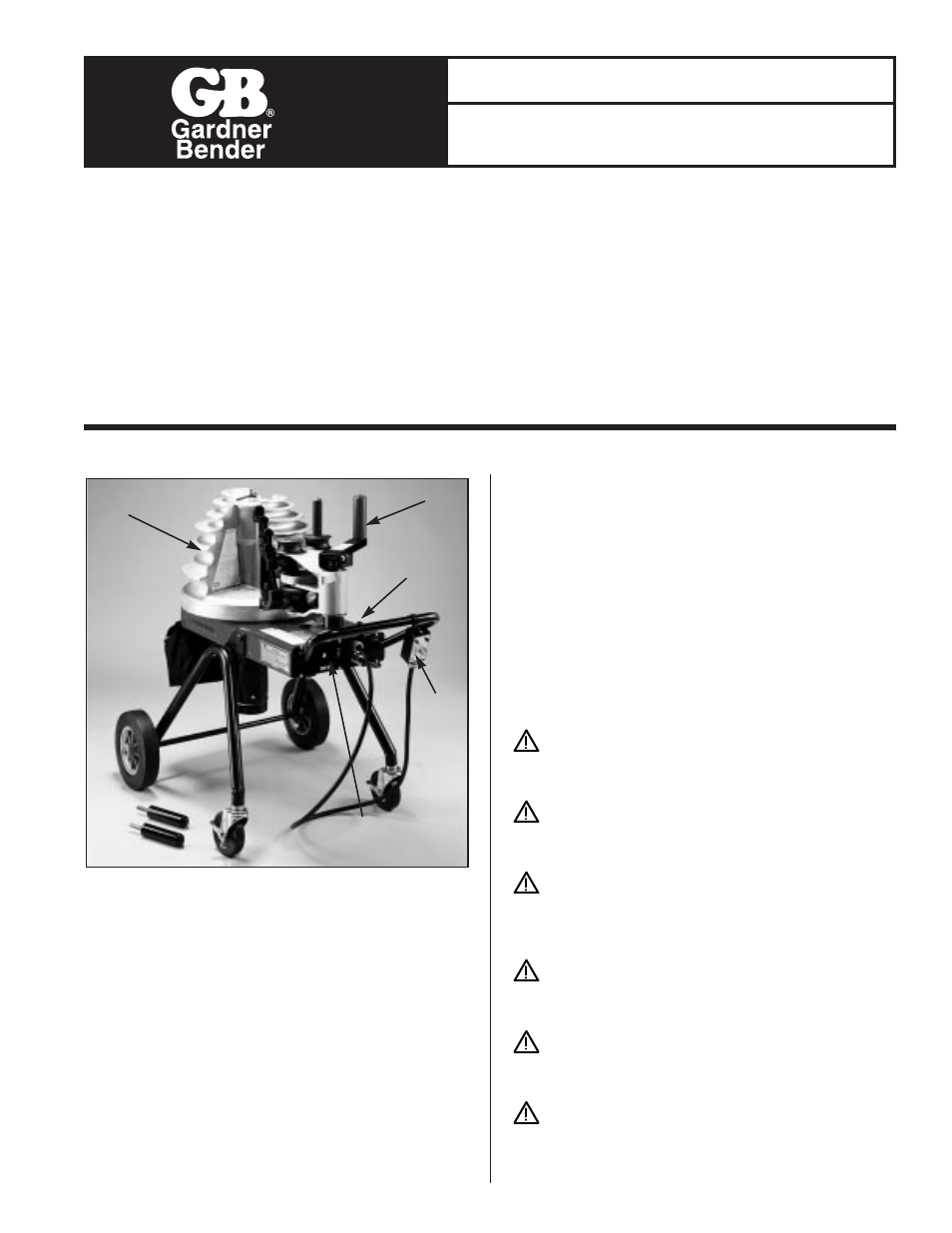

Bending Shoe

Pendant

Control

High/Low

Voltage

Indicator

Frame Stop

Upper Roller