7 maintenance and fault rectification, 1 maintenance, 2 remove interferences – Burkert Type 8111 User Manual

Page 22: 7maintenance and fault rectification

7

Maintenance and fault rectification

7

.1 Maintenance

If the instrument is used properly, no special maintenance is required

in normal operation.

7

.2 Remove interferences

The operator of the system is responsible for taking suitable measures

to rectify faults.

LEVEL SWITCH

8111 offers maximum reliability. Nevertheless, faults

can occur during operation. These may be caused by the following, e.

g.:

l

Sensor

l

Process

l

Voltage supply

l

Signal processing

The first measure to be taken is to check the output signal. In many

cases, the causes can be determined this way and the faults rectified.

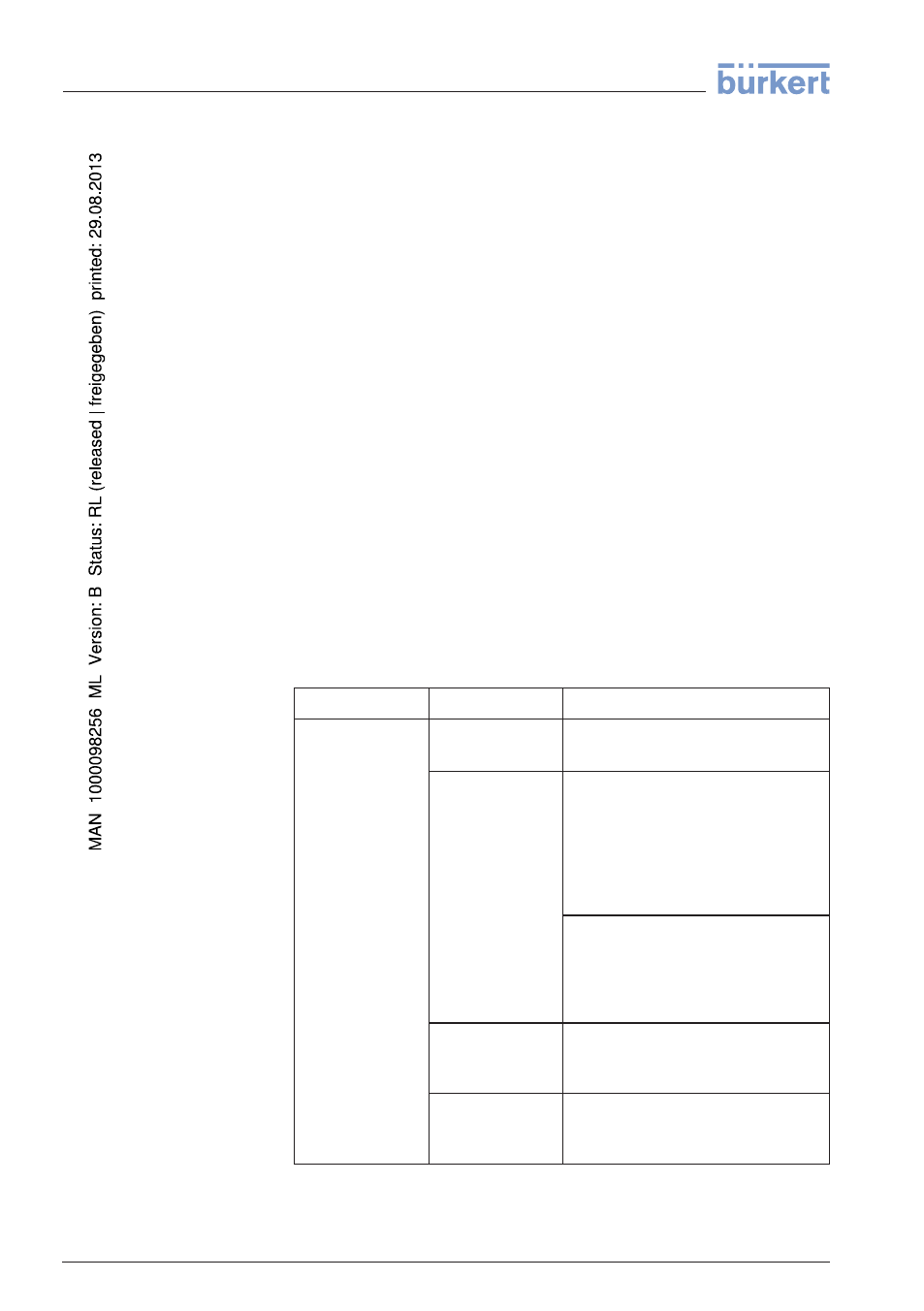

Error

Cause

Rectification

LEVEL

SWITCH

8111

signals "covered"

without being

submerged (over-

fill protection)

LEVEL

SWITCH

8111

signals "uncov-

ered" when being

submerged (dry

run protection)

Operating voltage

too low

Check operating voltage

Electronics de-

fective

Press the characteristic reversal

switch. If the instrument then changes

the mode, the vibrating element may

be covered with buildup or mechan-

ically damaged. Should the switching

function in the correct mode still be

faulty, return the instrument for repair.

Push the characteristic reversal

switch. If the instrument then does not

change the mode, the electronics

module may be defective. Exchange

the electronics module.

Unfavourable in-

stallation location

Mount the instrument at a location in

the vessel where no dead zones or air

bubbles can form.

Buildup on the vi-

brating element

Check the vibrating element and the

sensor if there is buildup and remove

it.

Reaction when malfunc-

tions occur

Failure reasons

Fault rectification

Checking the switching

signal

22

LEVEL SWITCH

8111 • with NAMUR output

7 Maintenance and fault rectification

32048

-EN

-120418