Burkert Type 8650 User Manual

Page 8

28

GB

Pneumatic valve type 6526/6527

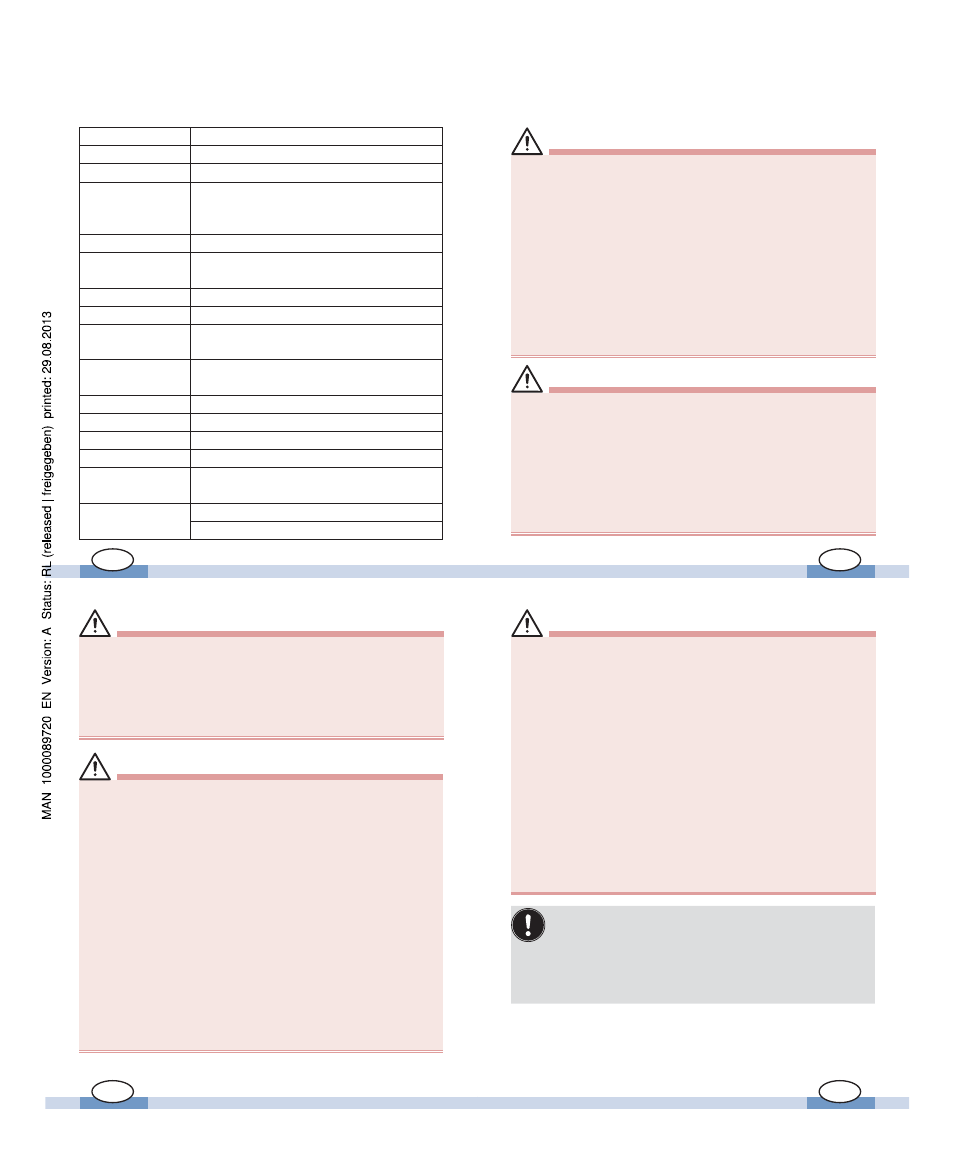

Technical data

Stacking size

16.5 mm

Material

PA (Housing)

Gasket material

NBR

Media

dry compressed air, oiled or oil-free

neutral gases (10 μm fi lter

recommended)

Line connection

Flange MP13

Pneumatic

module

Type MP13 with G 1/8“, NPT 1/8“ or

Type MP13 with plug connector Ø 8 mm

Manual actuation Yes (alternative versions without)

Rated power

0.3 W

Rated operating

mode

100 % continuous operation

Elec. connection

at the valve

rectangular plug RM 5.08 mm

Installation

with 2 screws M3 x 30

Orifi ce

6

QNn value air

700 l/min

Rated power

0.3 W

Pressure range

2 ... 8 bar

1 ... 8 bar (with auxiliary control air)

Switching times

Opening: 80 ms

Closing: 90 ms

29

GB

INSTALLATION

Safety Precautions

DANGER!

hazard due to high pressure!

Interference with the system will result in an acute risk of

injury.

Switch off the pressure and depressurise the system

before loosening pipes and modules!

Hazard due to electrical voltage!

Interference with the system will result in an acute risk of

injury.

Always switch off the power supply before starting work!

Observe all applicable accident prevention and safety

regulations for electrical equipment.

•

•

•

WARNING!

Hazard situations!

Unintentional operation or impermissible damage can lead

to dangerous situations including physical injury.

Take suitable measures to prevent unintentional operation or

inadmissible damage!

Ensure that the process is restarted in a defi ned and control-

led manner after an interruption in the electrical or pneumatic

power supply!

•

•

30

GB

WARNING!

During installation and maintenance operations, ha-

zardous situations may arise.

This work may only be carried out by authorised specialist

personnel who have been trained for working in explosive

atmospheres and using suitable tools!

CAUTION!

Power supply!

The device may only be operated with direct current.

Otherwise damage may be caused to the system.

Ensure that the device is connected only to a DC power

supply!

Pressure drop!

The pressure in the system may drop during switching.

Prevent pressure drops. Design the pressure supply sy-

stem with as large a volume as possible.

Seating of the seals!

If the seals are not seated correctly, leaks can occur resulting

in malfunctions due to pressure losses.

During installation, pay particular attention to the proper

seating of the seals in the area of the electronics and pneu-

matics.

•

•

•

31

GB

CAUTION!

Components / assemblies in the system susceptible to

electrostatic charges!

Observe the regulations of the EMC Act. The regulations

of the EMC Act are only satisfi ed with correct FE and PA

connections.

Electrical connection!

A reliable electrical connection requires exact contacting.

Do not bend the contacts!

If connections are bent or damaged, replace the components

concerned before switching on the system.

Possible limitations!

Observe the applicable limitations when converting / ex-

panding systems. Information can be found in the section

Intended use / Limitations).

•

•

•

Ensure a defi ned and controlled restarting of the

process after an interruption in the electrical or

pneumatic power supply!

Always pick up a preassembled system at the pneu-

matic supply modules and then remove it from the

packaging.

•

•