Brooks Instrument 3600 Series User Manual

Page 9

1-3

Section 1 Introduction

Installation and Operation Manual

X-VA-MT3600-eng

Part Number: 541B075AAG

February, 2011

Models MT3600, MT3601 & MT3602

O-rings

Standard: Viton

Optional: Silicone, Buna, Kalrez, EPR, Teflon, Metal (Teflon and Metal are

limited to Sizes 8 and 10, 316SS only)

Indicator Housing

Standard Housing: Aluminum with clear anodized finish and glass window

Optional Housing: 316 polished stainless steel and glass window

Alarm Housing, Cover and Isolation well

Standard: Cast aluminum alarm housing and cover with aluminum isolation

well, Neoprene

®

gasket seal, polyurethane paint, 3/4" NPT conduit

connection

Optional: Epoxy painted alarm housing and cover

Connections

Standard:

Model MT 3600: Socket-weld connections.

Model MT 3601: Flanged connections (150 lbs, 300 lbs or 600 lbs RF

ANSI B 16.5).

Model MT 3602: NPT (female) threaded connections.

Connection Orientation

Vertical inlet, horizontal outlet

Meter Dimensions

Refer to Figures 1-1 through 1-6

Pressure Equipment Directive (PED) 97/23/EC

Flow meter complies under Sound Engineering Practices (SEP), except

for Size 12. Size 12 Does not conform to Pressure Equipment Directive

97/23/EC, therefore it cannot be sold or used in the EU/EFTA.

1-4 Optional Equipment

ALARM LIMIT SWITCHES

Up to two reed switches provide initiation of alarm signal at preset flow

values. Settings can be adjusted by removing the alarm housing cover,

loosening, moving and retightening of the reed switch holders, and

replacement of the alarm housing cover. For greater power handling

capability, optional electromechanical relays are available.

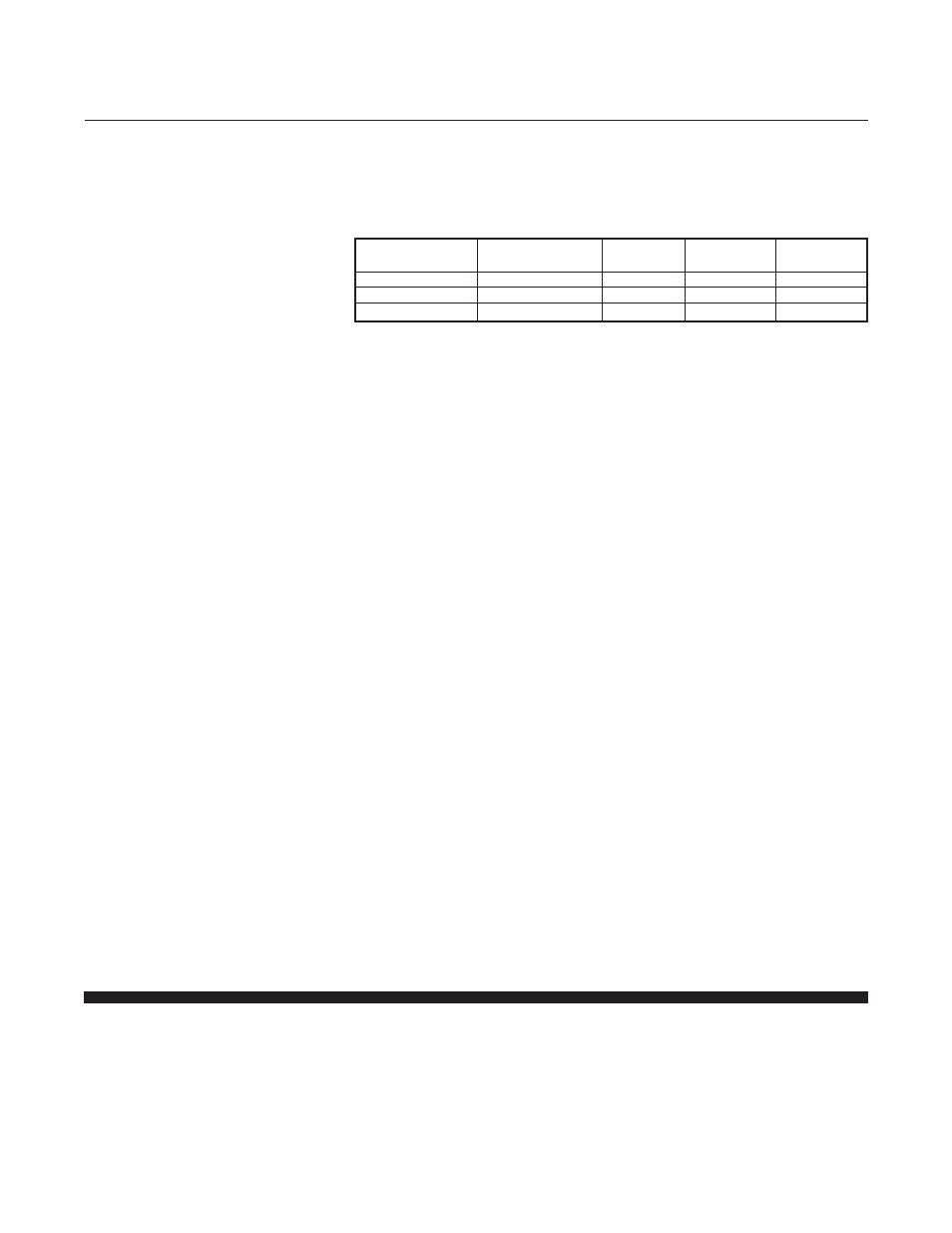

Table 1-2 Maximum Non-Shock Pressure Table

Maximum Pressure: Threaded and socket-welded meters: Up to 1500 psig at

200°F (93.3°C).

Maximum non-shock pressure (psi) versus temperature for ANSI standard pipe

flanges:

-20°F to 100°F

200°F

300°F

400°F

Flange Rating

(-29°C to 37.8°C)

(93.3°C)

(148.9°C)

(204.4°C)

150 lb. (316 SS)

275

240

215

195

300 lb. (316 SS)

720

620

560

515

600 lb. (316 SS)

1440

1240

1120

1030

Note: For pressure ratings of alternate materials consult the factory.