Flowline LD35 DeltaSpan User Manual

Page 4

4 of 16

MN301035

Rev B

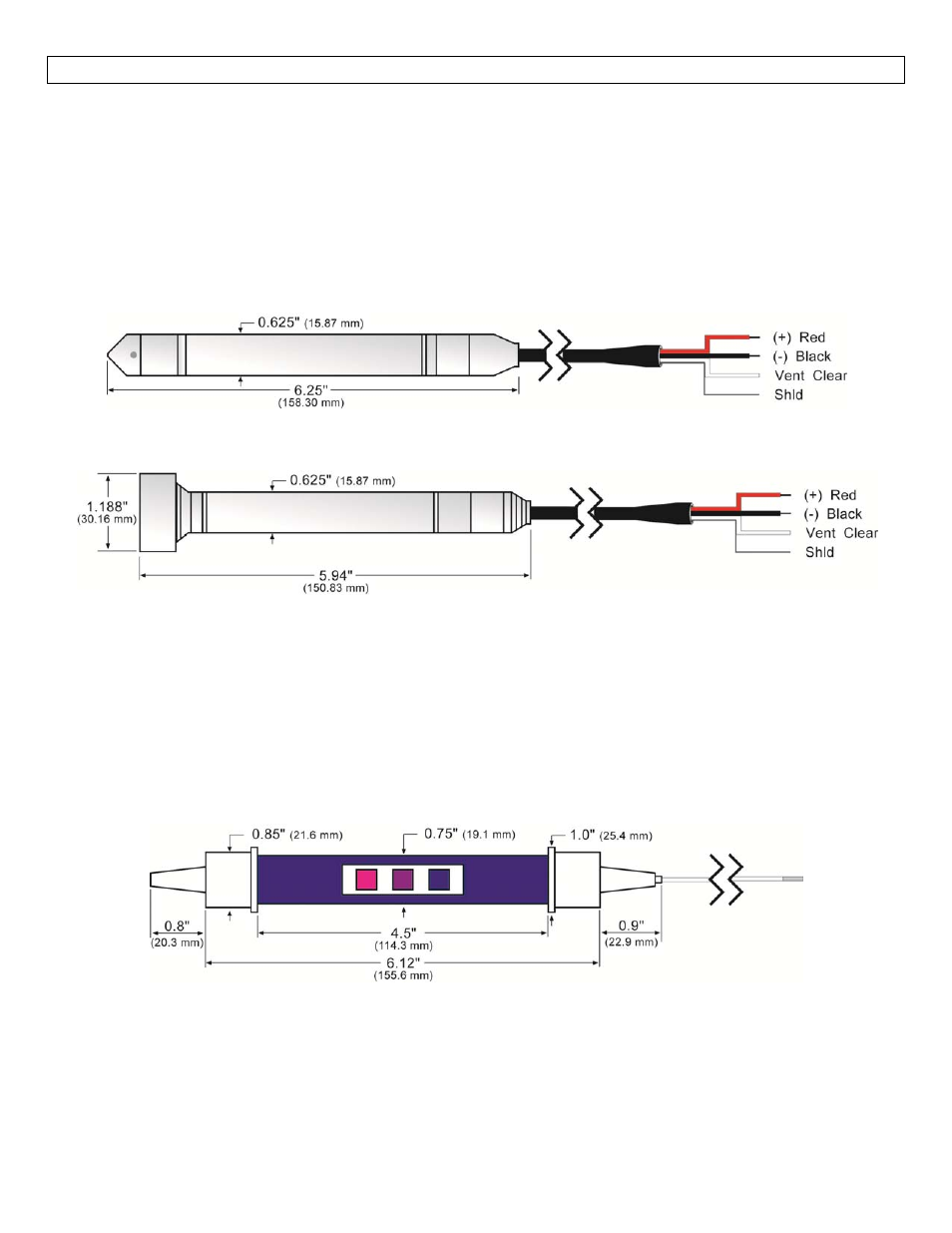

DIMENSIONS

Step Three

Technology: A sealed pressure transmitter is placed near or on the bottom of the tank. A stainless steel

pressure diaphragm within the pressure transmitter is exposed on one side to the application liquid. The

other side is exposed to the reference pressure via a small ventilation tube located inside of the Polyurethane

cable. A difference in pressure between liquid and reference pressures will slightly deflect the diaphragm.

The deflection of the diaphragm is measured by a built‐in microprocessor that provides greater linearity

correction over common thermal compensation methods. A 4‐20 mA current signal proportional the height of

the liquid is generated from the microprocessor.

LD34 Series

LD35 Series

Material Compatibility

o

The LD34 / LD35 series is made of 316 Stainless Steel (316 SS) with a cable of Polyurethane or Ethylene

Tetrafluoroethylene (ETFE). The LD35 series has a PTFE coated FKM fluoroelastomer face.

o

Make sure that the switch is compatible with the application liquids. To determine the chemical

compatibility between the sensor and its application liquids, refer to the Compass Corrosion Guide,

available from Compass Publications (858‐589‐9636).

Optional Desiccant Filter (LD90‐3000): For extra protection against humidity we offer the LD90‐3000

desiccant filter that can be attached to the vent tube.