Flowline LD35 DeltaSpan User Manual

Page 15

Rev B

MN301035

15 of 16

MAINTENANCE

Step Ten

After final installation of the pressure transmitter and its companion receiver, no routine maintenance is

required. A periodic check of system calibration is suggested. The pressure transmitters are not field

repairable and should be returned if repair is needed (field repair should not be attempted and may void

warranty). Be sure to include a brief description of the problem plus any relevant application notes. Contact

customer service to receive a return goods authorization number before shipping.

Maintenance should consist of inspection to see that the transmitter is free from debris and not coated with

any substance, which would prevent liquid from freely entering and leaving the transmitter. If this occurs, the

transmitter should be cleaned.

Testing the transmitter:

First, verify that the sensor is wired correctly.

Next, check if the power supply is providing the required power.

Finally confirm that the loop resistance is not exceeding the sensor’s specification.

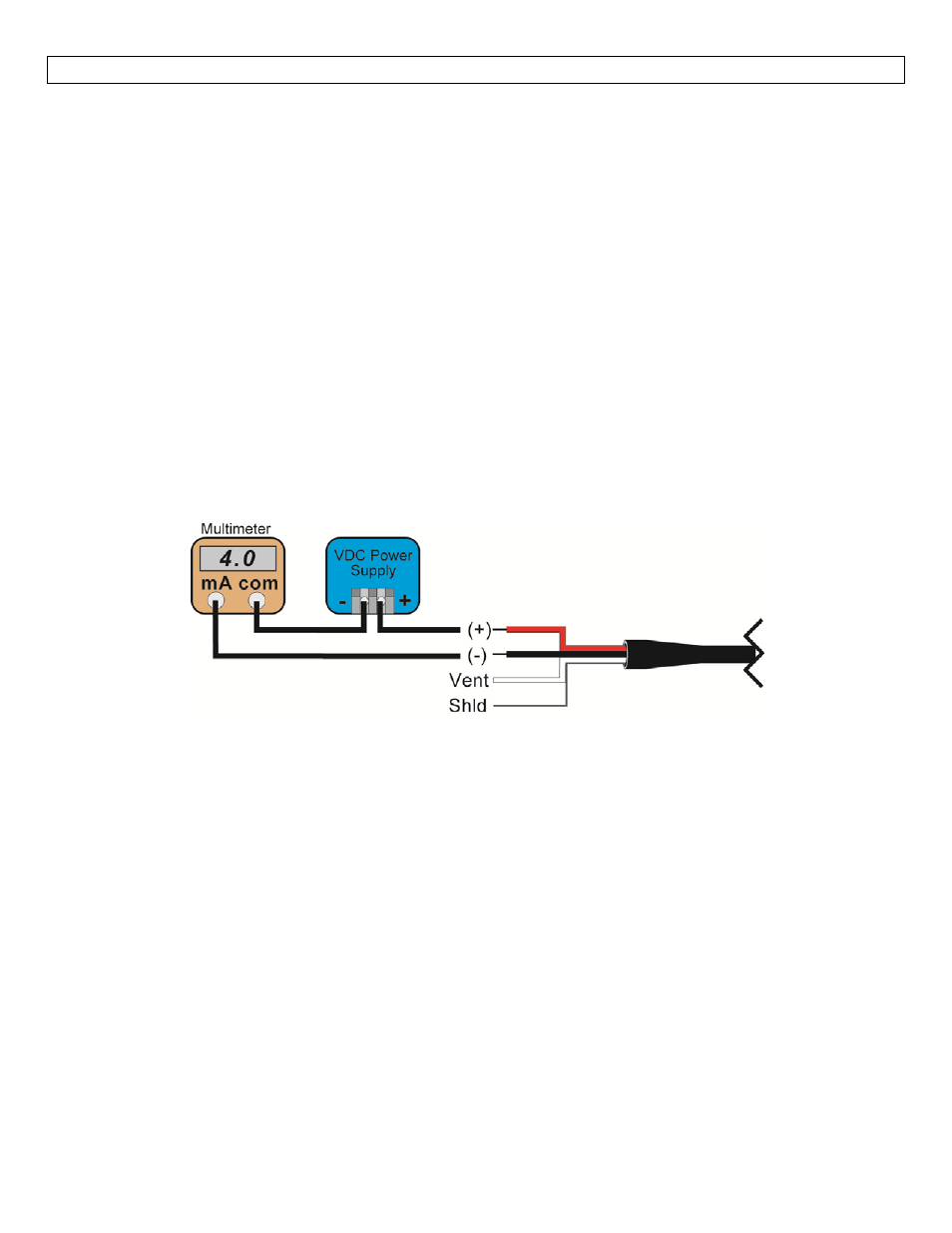

If transmitter is not functioning properly, isolate the transmitter from the system and wire as shown below.

Be sure to remove the sensor from the classified area when performing this test. Multimeter should read 4

mA with the transmitter out of liquid.