Flowline LD35 DeltaSpan User Manual

Page 14

14 of 16

MN301035

Rev B

INSTALLATION

Step Nine

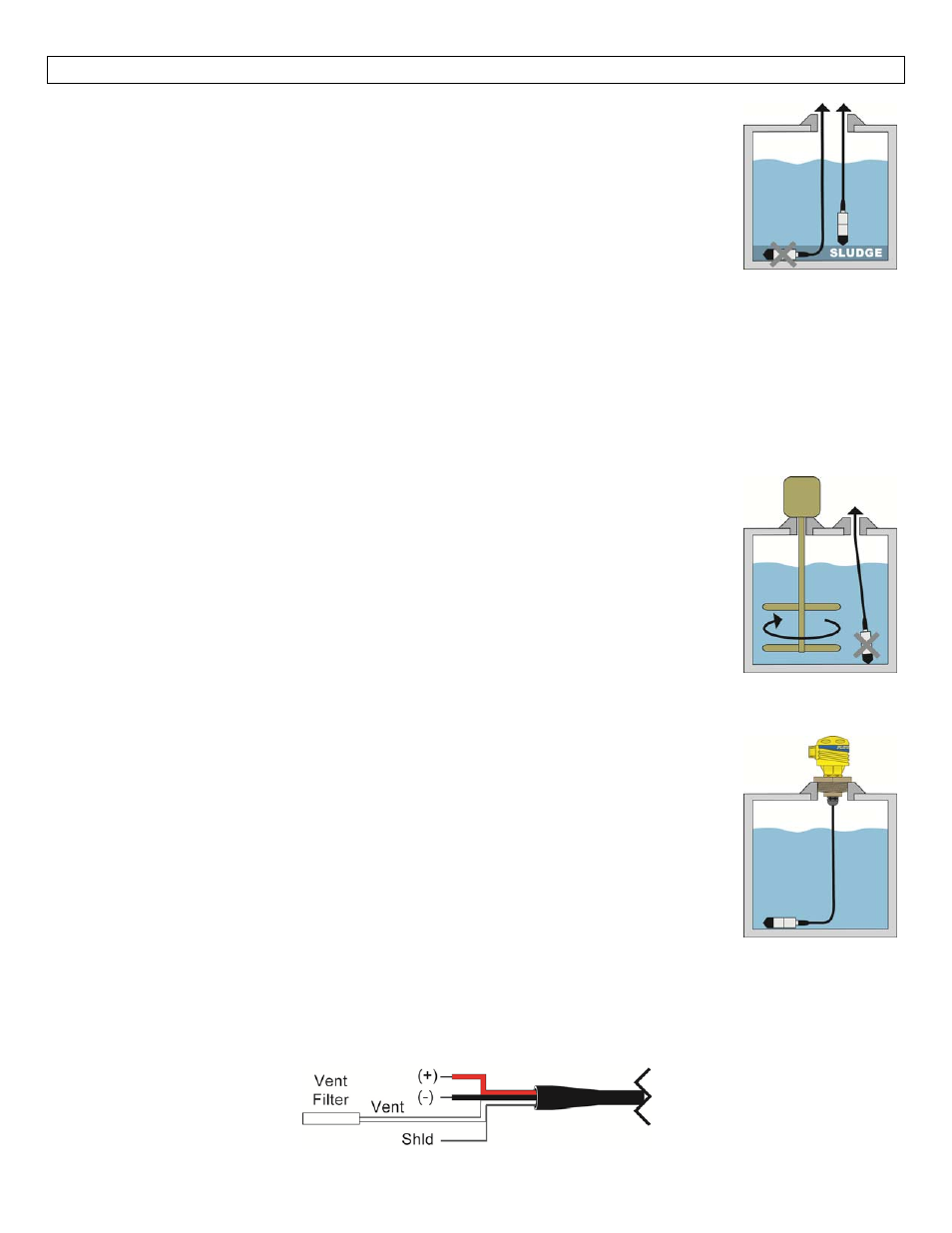

The LD34 / LD35 series are designed to operate while submerged in the actual

application liquid. Avoid installing the level transmitter along the bottom of the tank as

materials such as sludge will build up and coat/cover the transmitter. This also includes

any debris that will settle along the bottom of the tank. In these applications, it is best

to suspend the transmitter above the highest level of sludge/debris that will occur.

1. Location: Select a location where the temperature of the transmitter will be

between 0 and 176°F (‐18 to 80°C). Distance from the receiver is limited only by

total loop resistance.

2. Position: The transmitter is not position sensitive. However all standard models are originally

calibrated with the unit in a position with the pressure connection downward. Although they can be

used at other angles, for best accuracy it is recommended that units be installed in the position

calibrated at the factory.

3. Mounting: The transmitter can be mounted via several methods. It can be suspended from the

electrical cable, or it can be placed resting on the bottom of the tank in either horizontal or vertical

orientation.

Interference: The DeltaSpan™ is designed to operate under the surface of the liquid in

the tank. Avoid installations where other tank requirements will cause the transmitter

to move or swing. For example: a mixer blade could cause the level transmitter to whip

around within the tank. An alternative would be to move the transmitter to a more

stable section of the tank or to install the LD34/LD35 series inside a still well/drop tube.

The still well/drop pipe will minimize the effects created by the mixer.

Termination: The cable for the DeltaSpan™ is typically terminated at a junction box

located on top of the tank. Since the vent tube is contained within the cable, the

pressure within the junction box must always be the same as the reference (typically

atmospheric) pressure for the liquid. The inside of the junction box must be clean, dry and free of moisture.

Add the optional pressure fitting (LD90‐_001) to complete the package. The LD90‐_001

features a 2” NPT thread for mounting and a liquid tight connector to seal the cable

interface.

Note: Use caution when sealing the cable at the top of the tank. The ventilation tube

must be open and free to allow air to flow back to the pressure diaphragm. Avoid

blocking the ventilation tube by compressing the cable. Always keep the cable

termination clean, dry and free of moisture and prevent liquid from entering the vent

tube.

Note: A vent Filter is provided on the end of the vent tube. If the application requires

the vent tube to be cut to length, then remove the vent filter and place on the end of the new end of the vent

tube.

Note: For extra protection against high humidity environments, Flowline offers the LD90‐3000 desiccant filter

that can be attached to the vent tube.