Flow meter specifications – Fill-Rite TS SS Electronic Precision Meter User Manual

Page 9

Flow Meter Specifications

Model Nominal Pressure Rating¹ at 100°F (38°C):

Flow Meter

² 400

PSI

28

BAR

2750

kPa

Strainer²

400

PSI

28

BAR

2750

kPa

Air Eliminator

150

PSI

10

BAR

1035

kPa

Solenoid Valve

depends upon valve type/model

(1) Pressure rating is reduced at higher operating temperatures.

(2) With optional 150# RF ANSI flanges pressure rating is

285 PSI = 20 BAR = 1965 kPa.

Model Nominal Temperature Rating:

Design

temperature:

-40°F/+300°F -40°C/+150°C

Pulser ATEX listing : -4°F/+140°F -20°C/+60°C

If the operating temperature can exceed +120°F (+50°C),

use high temperature (HT) rotors, code L (or M).

Model Nominal Capacity on low viscosity liquids (1 cP):

TS10C

40 GPM 150 lpm 9 m³/h

TS15C

60 GPM 230 lpm 14 m³/h

TS20C

150 GPM 570 lpm 34 m³/h

TS30C

250 GPM 10 00 lpm 60 m³/h

Optimum performance (accuracy & service life) is between

50% and 85% of nominal capacity.

On low viscosity, lubricating liquids, intermittent service to

125% of nominal capacity is acceptable.

NTEP approvals are with 5:1 turn-down.

OIML approvals are with 10:1 turn-down.

Meters may be used at lower flow rates, but meter error in-

creases below 10% of capacity on low viscosity liquids.

On higher viscosity liquids, error at low flow rates diminishes

progressively. Over 100 cP performance should be accepta-

ble to 3-5% of capacity, over 1000 cP performance should be

acceptable to 1-2% of capacity.

Liquid Viscosity³:

With standard LV rotors, meters may be used to full nominal

capacity up to 300 cPs (1500 SSU). When viscosity can

exceed 300 cPs (1500 SSU), high viscosity (HV) rotors,

code I (or J) are strongly recommended.

With HV rotors, meters may be used to full nominal capacity

up to 1000 cPs (4700 SSU). In high viscosity service, flow

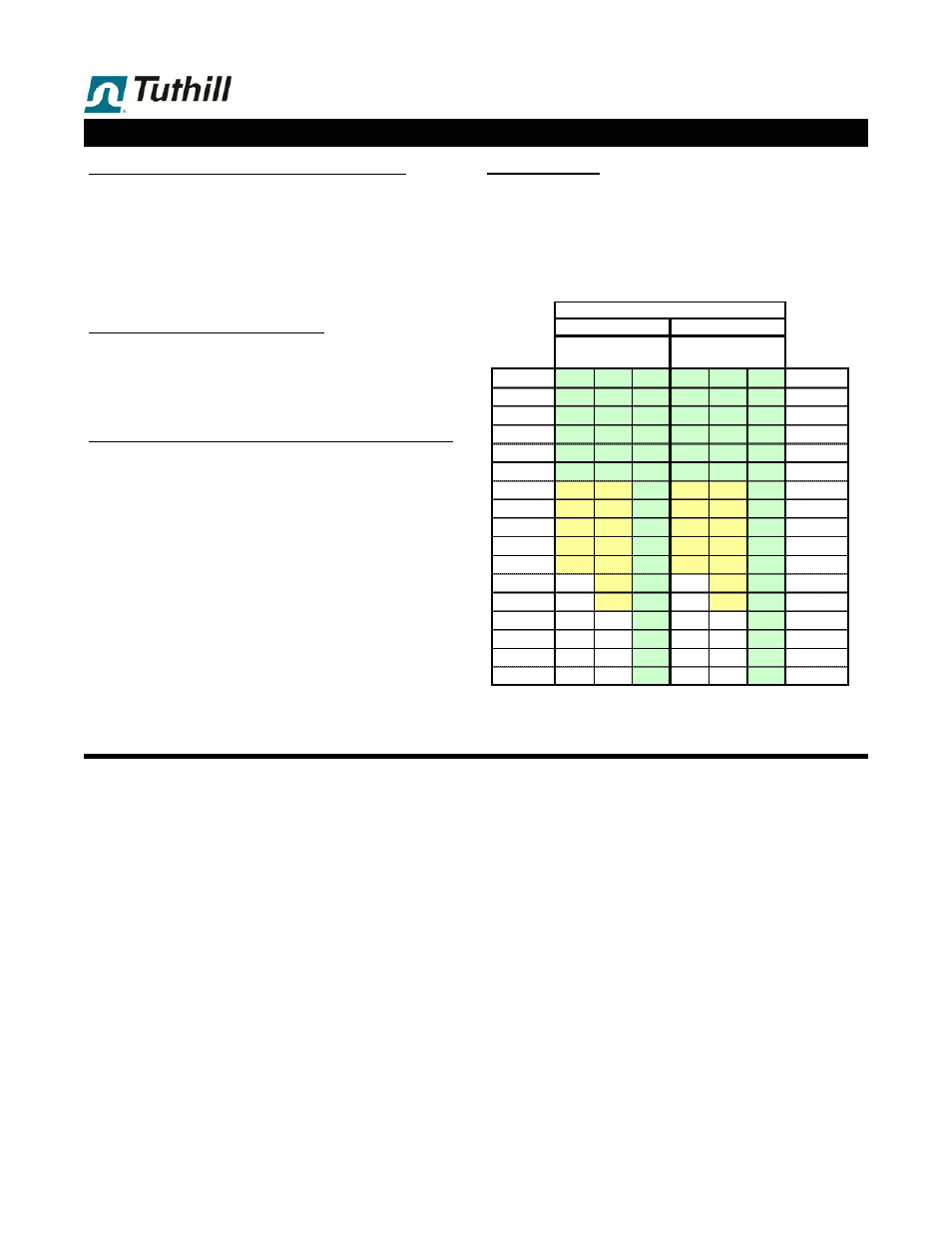

meter capacity is reduced according to this table:

(3) Teflon bearings are used primarily on shear sensitive

liquids, such as many resins & adhesives.

B

L

I

C

M

J

cP

1 1.00 1.00 1.00

1.00 1.00 1.00

32

SSU

10 1.00 1.00 1.00

1.00 1.00 1.00

60

50 1.00 1.00 1.00

1.00 1.00 1.00

240

100 1.00 1.00 1.00

1.00 1.00 1.00

475

200 1.00 1.00 1.00

0.90 0.90 1.00

925

300 0.86 0.86 1.00

0.73 0.73 0.98

400 0.77 0.77 1.00

0.62 0.62 0.96

500 0.71 0.71 1.00

0.57 0.57 0.94

600 0.66 0.66 1.00

0.53 0.53 0.92

700 0.63 0.63 1.00

0.50 0.50 0.90

800 0.60 0.60 1.00

0.48 0.48 0.85

900

0.56 1.00

0.45 0.80

0.54 1.00

0.43 0.75

0.53

0.42

0.41

0.32

0.11

0.09

0.05

0.04

Flow Meter Coefficient

Standard

Teflon brgs.

Rotor Code

Rotor Code

23,600

Liquid

Viscosity

47,200

4,720,000

472,000

1,000,000

100,000

10,000

1,000

5,000

Liquid

Viscosity

4,725

4,250

3,775

3,300

2,825

2,350

1,875

1,425

Rotors : PPS (polyphenylene sulfide resin),

carbon

bearings

standard,

Teflon™

bearings

optional

Rotor

shafts

: HC316SS

Internal fasteners : 300 Series SS

Seals : Teflon™ standard,

Meter body & covers:

316 (CF8M) Stainless Steel

Carbon

0.08%

Manganese 1.50%

Phosphorous 0.04%

Sulfur

0.04%

Silicon

1.50%

Chromium 18.0-21.0%

Nickel

9.0-12.0%

Molybdenum 2.0-3.0%

Iron remainder

Shafts for oval gears:

316 Stainless Steel

Carbon 0.10% max.

Manganese 2.0% max.

Silicon 1.0% max.

Chromium 16.0-18.0%

Nickel 10.0-14.0%

Molybdenum 2.0-3.0%

Iron remainder

1 .9