Flow meter - disassembly and repair – Fill-Rite TS SS Electronic Precision Meter User Manual

Page 11

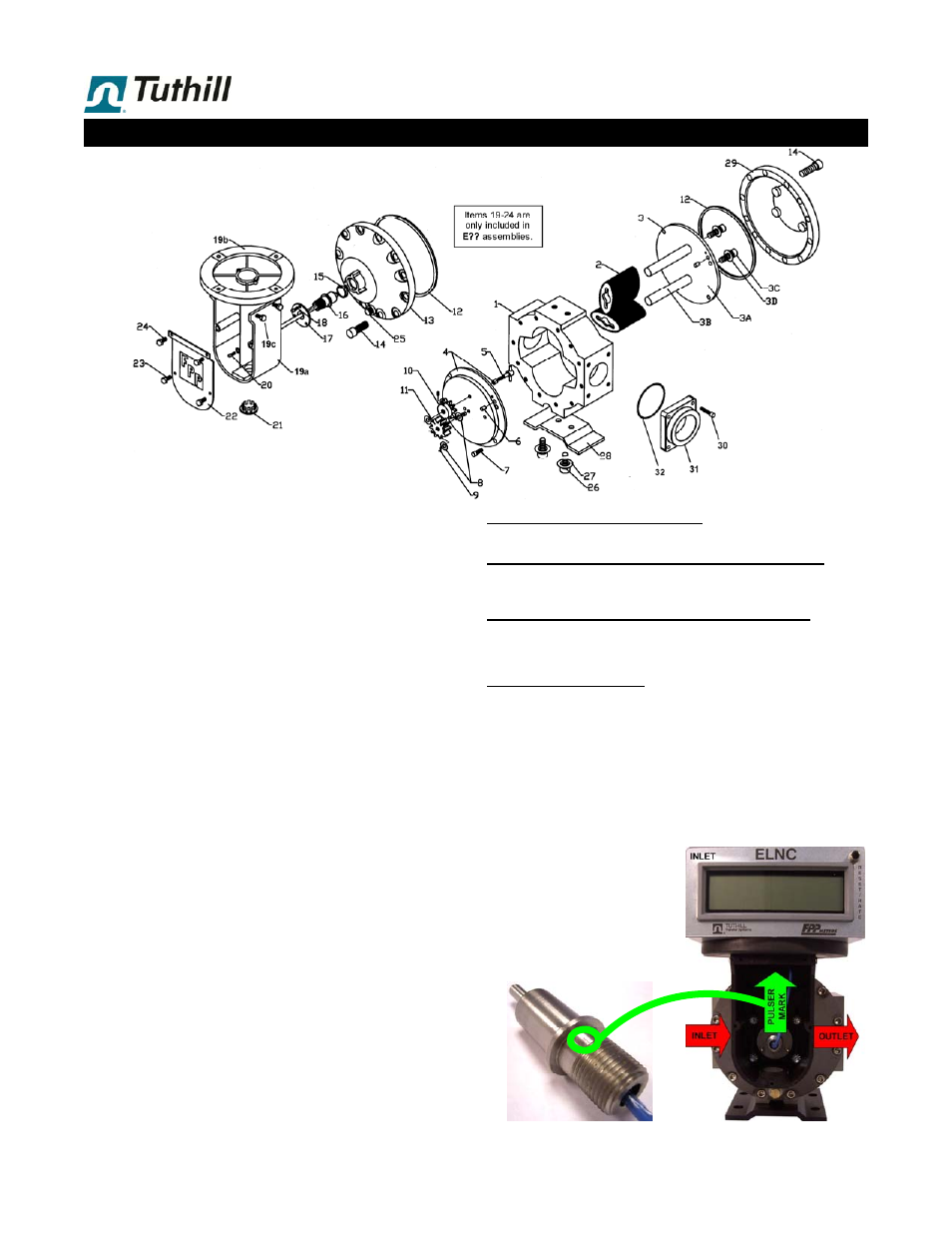

Regular Maintenance (1-3 years)

A. Pulser O-ring (15)

Very Long Term Wearing Components (3-10 years)

B. Transfer Gear/Disc Magnet repair kit (10 & 11)

C. Oval Gears (2)

Longest Term Wearing Components (5-20 years)

D. Post Plate assembly (3, a-d)

E. Bearing/Gear Plate (4)

Electronic Components

The electronic components have an indefinite life expectan-

cy, but can fail if the system is wired incorrectly, poorly

grounded, or cables used are not to minimum standard re-

quired.

While we do not expect that these components will need

replacement, instructions are provided in case it should be-

come necessary. Any time a pulser has been removed or

replaced, it is

critical,

that it be aligned correctly when

re-installed:

Whether flow is L-to-R,

or R-to-L, mark on Hall

Effect pulser body must

point exactly towards

12 o’clock position, when

meter inlet & outlet are

in the horizontal plane.

1 . 11

Flow Meter - Disassembly and Repair

Installation, Maintenance & Service must be performed

by personnel:

A. Qualified to work on this type of equipment.

B. Familiar with all applicable local codes and ordinanc-

es covering the type of service, where the flow meter

is used (gasoline, LPG, etc.).

Avoid pipe strain and stress when making flow meter repairs.

The weight of the pipe and the flow meter must be supported

independently. This allows the flow meter to be serviced

without affecting the alignment of piping.

Avoid prying or exerting heavy pressure on precision parts,

as this can affect the performance of the flow meter. Assure

that all machined parts are free of burrs and nicks. Stone all

machined surfaces if necessary to remove burrs.

Always coat bolt threads with an anti-seize or an appropriate

lubricant. This prevents thread damage, and assures that

proper torque values are applied during re-assembly.

If threads are damaged, repair using inserts.

Relieve All Internal Pressure Prior to Opening

Drain Liquid prior to Working on Flow Meter

(drain plug = #25)

Rinse with Neutral Liquid prior to Seasonal Storage

Triple Rinse with Neutral Liquid

prior to Shipment for any reason.

Servicing the Electronic Flow Meter

There are only 5 parts or components, which will require in-

spection and/or replacement at some point. In the order they

are likely to occur, these are: