Reversing direction of flow, Start-up & operation – Fill-Rite TS SS Electronic Precision Meter User Manual

Page 5

Reversing Direction of Flow

When a flow meter has been ordered for Left-to-Right flow,

but Right-to-Left is found to be more practical, the flow meter

can be re-assembled in the field.

The electronic flow meter can operate in either direction.

However, if the electronic register is utilizing the quadrature

pulse signal, the leads must be reconnected to reflect the

change in direction of flow.

The strainer (with or without air eliminator) can be trans-

ferred to the other side of the flow meter.

Solenoid valves can be moved to the other side of the flow

meter without any further modifications.

1 . 5

Installation, Start-Up/Operation & Direction of Flow

When an Air Eliminator is included in the flow meter

assembly, the strainer/air eliminator must be in horizontal

position, since the air eliminator operates on a gravity

principle. A few drops of liquid may be expelled when the

air eliminator vents, so vent ports should be piped back to

storage or to a collection tank (sloping towards the tank).

Thermal relief valves are recommended

, and should be

installed whenever it is possible to block (isolate) the flow

meter between two valves. The pressure rise in a closed

system, from just a few degrees increase in temperature,

can be many times normal working pressure.

Connections for calibration

should be provided during

installation. An easy means for diverting flow into a cali-

bration vessel (or master meter) should be considered.

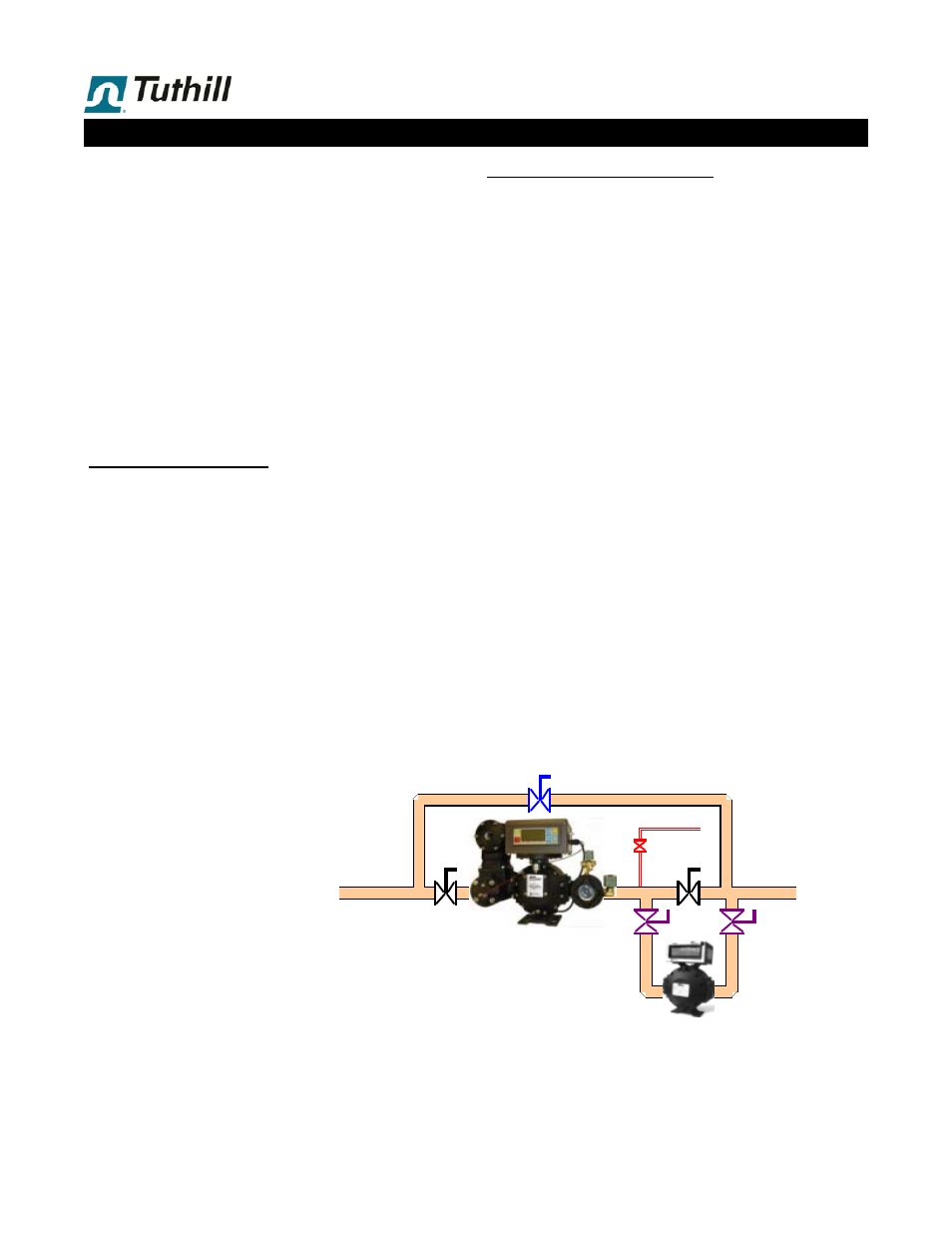

Refer a diagram for the suggested installation is shown

below.

Start-Up & Operation

Very slowly fill the system with liquid, to avoid operating the

flow meter on air or vapor. This can be accomplished in the

following manner:

1. Throttle the meter inlet valve, and allow the system to fill

slowly by gravity.

2. Crack open the outlet valve. Start the pump, and then

slowly crack open the inlet valve, filling the meter slowly

before fully opening the inlet and outlet valves.

In normal operations:

Avoid sudden changes in temperature.

Avoid sudden changes in flow rate.

Gradually increase or decrease the flow rate.

TRV protects portion of system, which can be

isolated between valves IV1, CV1 & IV2.

Calibration Connection valves

Thermal Relief valve

IV1 & IV2:

CV1 & CV2:

BPV:

TRV:

B Y - PA SS LIN E

IV1

IV2

: IV2 & BPV closed, other valves open

TRV

: IV1 & IV2 closed (by-pass open)

During Calibration

: BPV, CV1 & CV2 closed

TEMPORARY MASTER METER

CV2

OPERATING FLOW METER

Normal Operation

BPV

Service/Maintenance

CV1

Isolation Valves

By-Pass valve

(or Prover Tank)

OPT ION A L

The optimum flow meter installation should include

the components & features shown in this diagram.