Drill Doctor 400 User Manual

Page 21

19

www.DrillDoctor.com

Determining If a Change of the

Diamond Sharpening Wheel Is Required

Reverse the grinding wheel before you replace it. The grinding

wheel supplied with the Drill Doctor

®

is designed to give you

long and trouble free service, with an average of more than 200

sharpenings.

The diamond wheel may need to be changed if:

1. Sharpened drill bits burn or turn blue no matter how fast

or slow you rotate the chuck.

2. When touching the sharpening wheel (with the machine

disconnected), the lower portion feels too smooth

(nonabrasive).

3. When sharpening the drill bit, it takes too many half-

rotations to sharpen.

If you sharpen only 3/32" to 1/2" bits, you can double the life of

the diamond wheel by reversing it. Bits larger than 1/2" use the

entire diamond wheel surface so reversing will not be an

advantage. Contact the store or dealer where you purchased

the Drill Doctor

®

to purchase a standard or coarse replacement

sharpening wheel.

Reversing or Replacing Your Diamond

Sharpening Wheel

Unplug your Drill Doctor,

®

make sure machine is cool, then

remove wheel cover.

1.

2.

3.

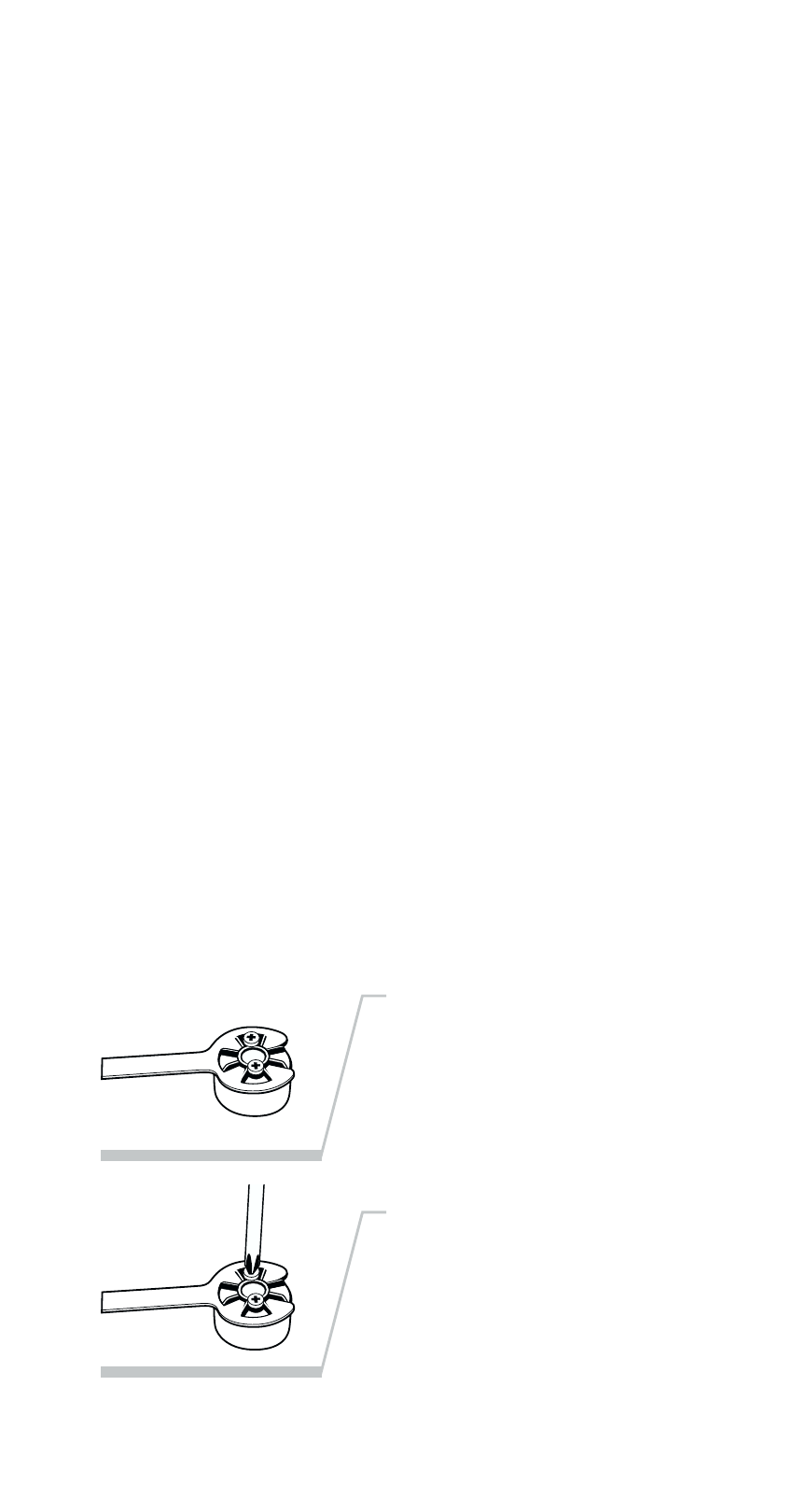

With Phillips-head screwdriver,

remove the two screws and

wheel retainer.

Use wrench supplied with your

Drill Doctor

®

to lock sharpening

wheel in place.