Drill Doctor 400 User Manual

Page 12

10

www.DrillDoctor.com

2.

3.

1.

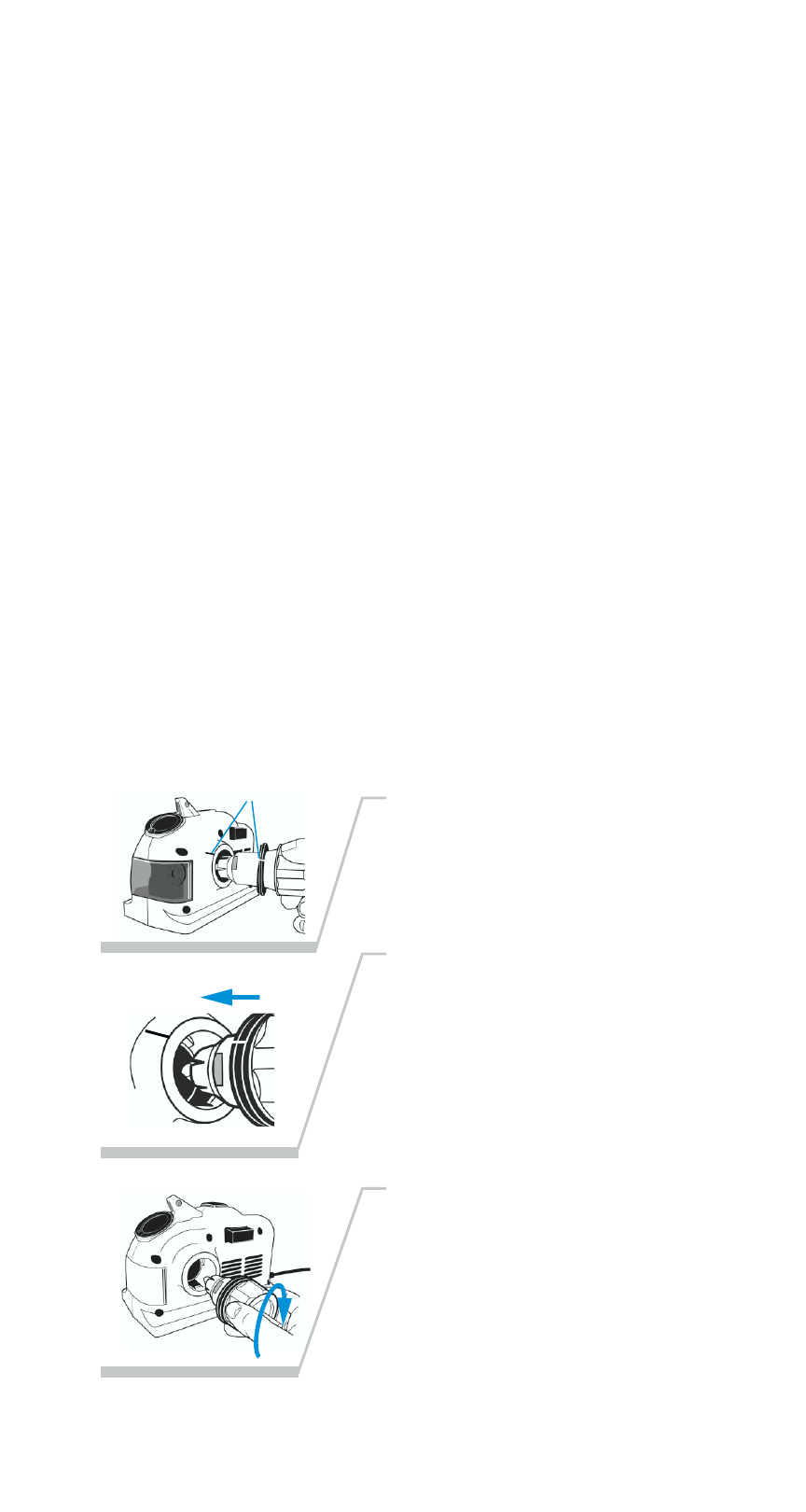

With the machine turned on,

match the white line on the

Chuck with the white line next

to the Splitting Hole.

Split Points

Split point drill bits prevent walk-around on the material before

they begin to cut.

This feature is described as self centering. The need to center

punch is effectively eliminated. A standard drill bit chisel point

has to wear an area in the middle of the hole to be drilled before

the cutting edges will remove material. Due to its additional

cutting lips along the chisel edge, a split point will begin cutting

immediately. Up to 70% less thrust (when compared to a non-

split or conventional point) is required to drill a hole with a split

point.

Creating or Replacing a Split Point

Always align and sharpen a bit before splitting it. With the

Splitting Hole facing you, notice that the Splitting Hole has flat

spots like the Alignment Hole and a white mark on the case

next to the Hole. When inserting the Chuck into the Hole, align

the white mark on the Chuck with the white mark on the case.

As you push the Chuck slowly into the Hole, the flat spots on

the Chuck and in the Hole should match. The Chuck will be tight

in the Hole.

Insert the Chuck into the Splitting

Hole so the flat spots match

(white line to white line) and

push slowly and firmly until

the Chuck stops (you will hear a

grinding sound). Push hard until

the Chuck stops.

Pull the Chuck out slightly until

the flat spots release, and turn it

a half-turn either way. With the

white lines and flat spots aligned,

push it in firmly and slowly

until it stops. The second side of

the bit is now split.

White Marks