Drill Doctor 400 User Manual

Page 11

9

www.DrillDoctor.com

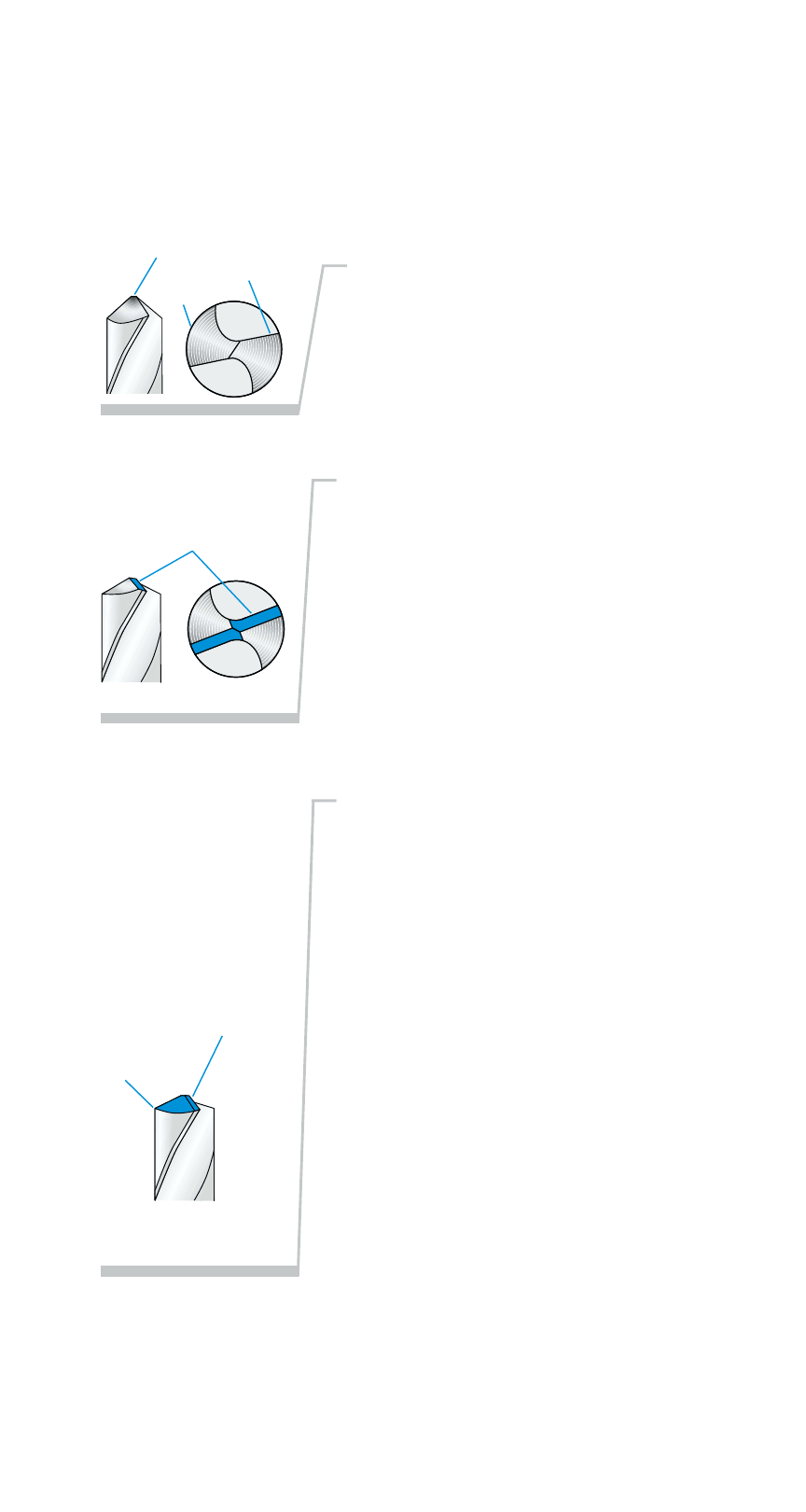

Identifying Correctly-Sharpened Drill Bits

(And What to Do With Those That Aren’t!)

The entire surface from the Cutting

Edge to the Heel will have a finely

ground surface without ridges or

indentations. And, the Heel will

always be lower than the Cutting

Edge.

Correctly Sharpened

Cause

Bit Clamps did not grip drill bit at

narrowest point in the aligning process

(Page 6).

Solution

Realign the bit by carefully following

steps 1 through 10 on Pages 4 to 7.

Cause

Sharpening Hole not functioning

properly.

Solution

The Sharpening Hole is where you

rotate the Chuck when sharpening.

Locate the bump on the bottom of the

Hole and press down on it. If the tube

does not spring back, please call our

Technical Support group at 1-800-597-

6170 or 541-552-1301 for assistance.

Cause

Dirty Chuck.

Solution

Insert a drill bit into the Chuck, tighten

Misaligned

Heel

The Chisel Edge is

ground flat.

Heel

Same Height

or Higher

Than the

Cutting Edge

Chisel Point

Cutting Edge

it, then press the bit against a hard surface. Does the bit slide

in the Chuck? If so, clean the Chuck as described on Page 18.

Cutting Edge

Heel