Questions and answers – Drill Doctor 400 User Manual

Page 16

14

www.DrillDoctor.com

Questions and Answers

1. Question:

When I aligned the drill bit and sharpened it, why was no

material removed?

Answer:

This happens when the bit is not protruding out of the Chuck

far enough. You may have allowed the Alignment Button to

knock the drill back into the Chuck when aligning the bit.

Carefully realign the bit in the Alignment Hole again. Make sure

the drill is pushed all the way against the Drill Stop before you

release the Alignment Button.

2. Question:

I sharpened the bit. Why will it not cut?

Answer:

This happens when the heel on the bit is higher than the cutting

edge (negative relief). Realign the drill and resharpen in the

Sharpening Hole.

Maintain consistent inward light pressure during the half-turns

of the Chuck.

You may have a specialty drill bit. Slow and Fast Spiral, Helix,

Turbo Flutes, and Raised Margin drill bits are considered specialty

bits. To sharpen them, align them in the

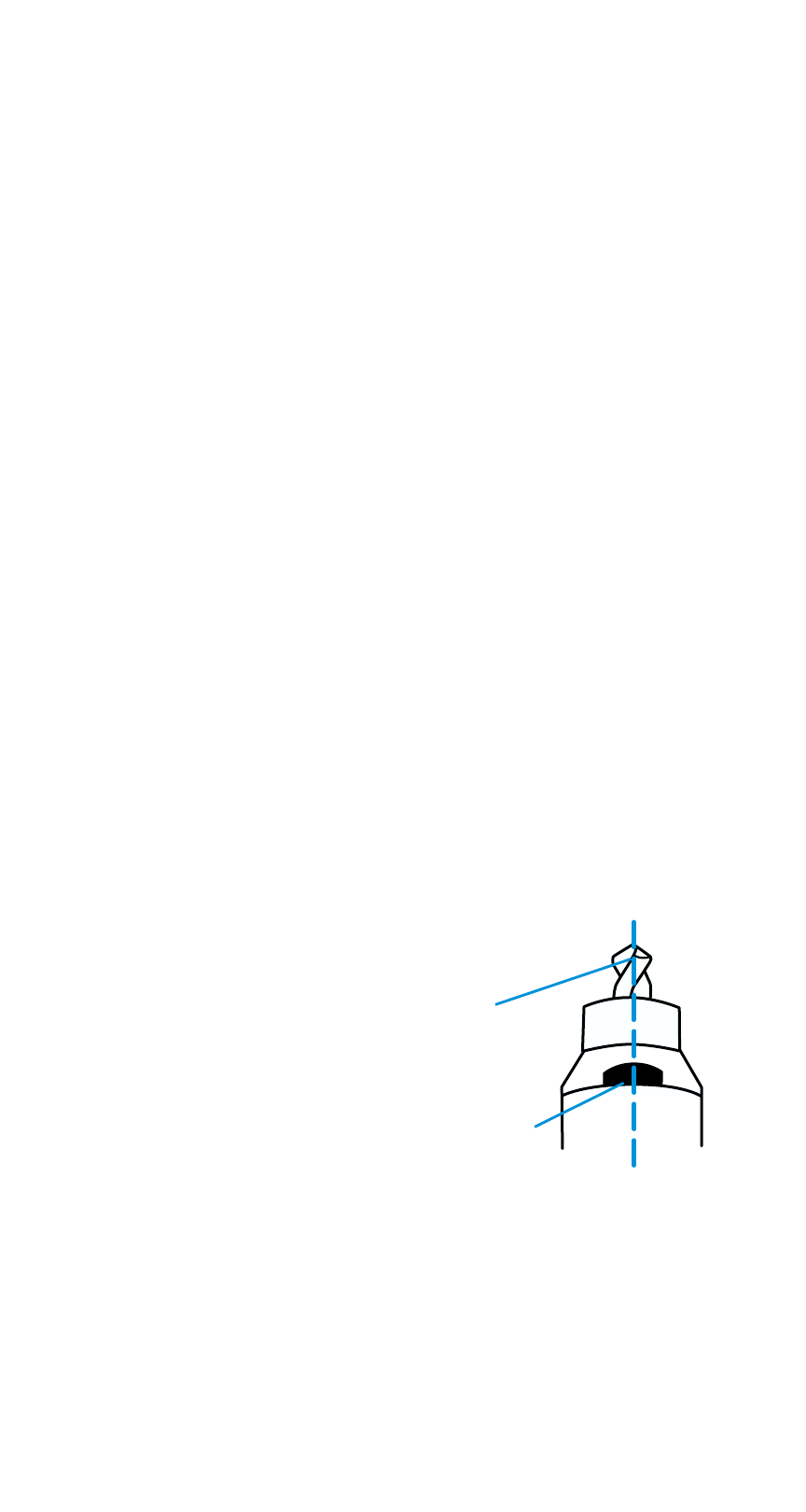

Chuck as you do standard bits. Check the

position of the two Flats on the

Chuck and draw an imaginary line

from the middle of the flat up

through the drill bit (3/32" to 1/2").

When aligning, start with the Bit

Clamps on the narrow part of the

bit, then turn the bit clockwise to

approximately the 1:00 o’clock position. Hold the bit so it will

not move and tighten the Chuck. You may have to move the

drill bit clockwise in the Chuck more than once until it sharpens

correctly.

If the chisel edge moves too far to the right, realign the bit and

adjust again.

Heel

Flat Spot