Chapter 4 – maintenance and adjustments 33 – Datamax-O'Neil E-Class Mark III 3xxxxxxx Operator’s Manual User Manual

Page 39

Chapter 4 – Maintenance and Adjustments

33

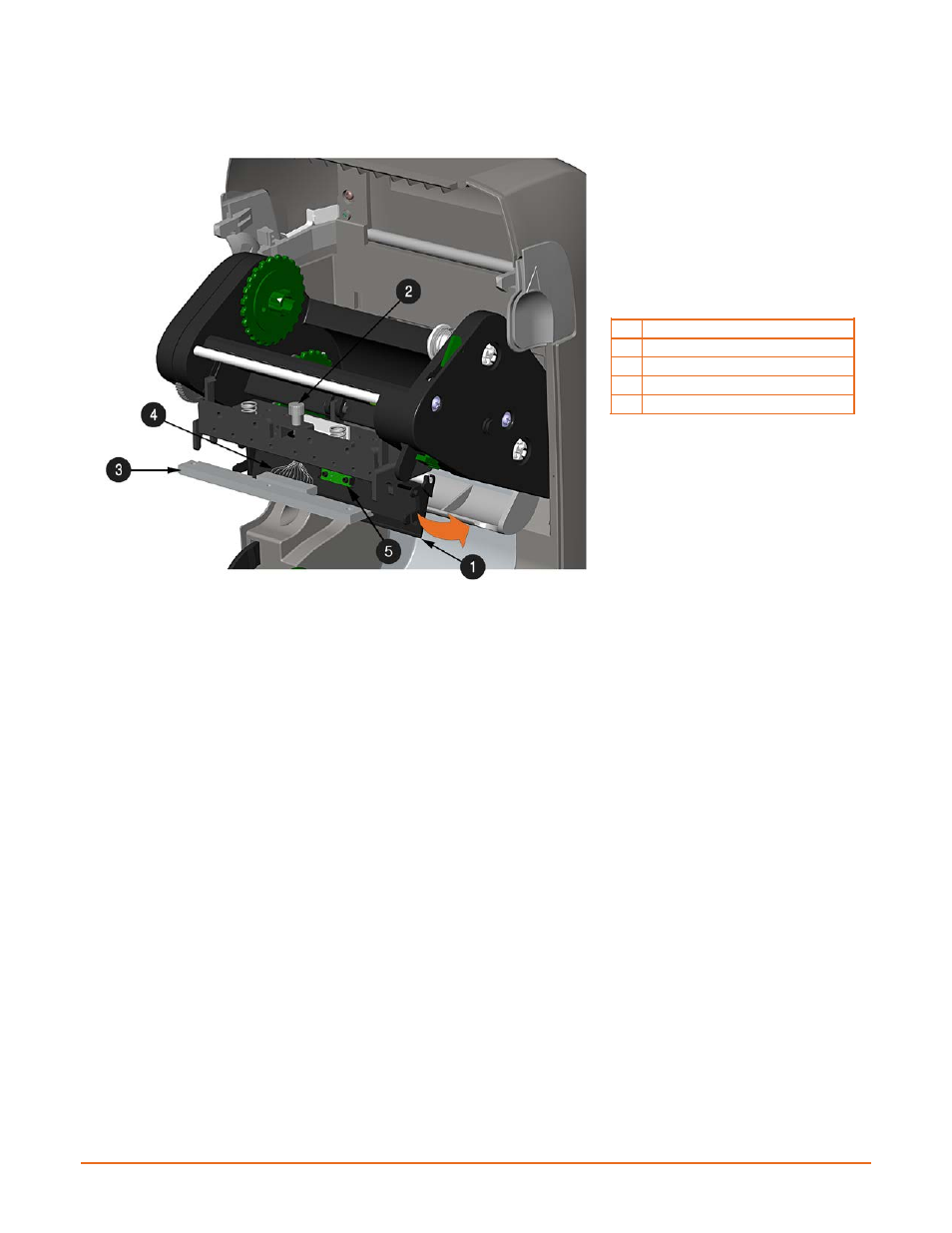

5) Loosen the Printhead Screw and allow the Printhead to fall free.

6) Remove the Printhead Cable.

312

Printhead Shield

Printhead Screw

Printhead

Printhead Cable

Sensor

Installation:

1) Carefully connect the Printhead Cable to the new Printhead.

2) Position the Printhead in the Printhead Carrier and tighten the Printhead Screw.

3) Ensure the Sensor properly seated and rotate the Printhead Shield upward until it snaps into

place.

4) Rotate the Printhead Carrier upward until it snaps into place.

See also other documents in the category Datamax-O'Neil Printers:

- MF8I 270 User Guide (20 pages)

- MF8I Installation Guide (18 pages)

- MF8I Truck Mount Cable (2 pages)

- MF8I Locking Mounting Bracket (2 pages)

- MF8I Economy Mounting Bracket (2 pages)

- MF8I AN-15 (Line Printer and Easy Print Modes) (7 pages)

- MF8I AN-16 (Single Byte Character Set Font File Format) (8 pages)

- MF8I Quick Reference Programming Guide (72 pages)

- MF8I Configuration Program Installation (1 page)

- MF8I Bluetooth Management Component for Wavelink Avalanche (10 pages)

- A-Class Mark II Operator’s Manual (160 pages)

- A-Class Mark II Installation (2 pages)

- A-Class Mark II DMXrfNetIII (16 pages)

- A-Class Mark II DMXrfNetII (16 pages)

- A-Class Mark II RFID Quick Start Guide (6 pages)

- A-Class Mark II Programmer’s Manual (334 pages)

- ANDES 3 User Guide (32 pages)

- ANDES 3 Quick Start Guide (2 pages)

- ANDES Series Programmer’s Manual (67 pages)

- APEX 2 User Guide (28 pages)

- APEX 2 Quick Start Guide (2 pages)

- APEX 3 User Guide (27 pages)

- APEX 3 Quick Start Guide (2 pages)

- APEX 4 User Guide (30 pages)

- APEX 4 Quick Start Guide (2 pages)

- E-Class Mark III Operator’s Manual (90 pages)

- E-Class Mark III 4xxxxxxx Operator’s Manual (58 pages)

- E-Class Mark III Paper Menu (7 pages)

- E-Class Mark III DPL Programmer’s Manual (296 pages)

- E-Class Mark III Printhead Bracket and Screw Upgrade (11 pages)

- H-Class Operator’s Manual (180 pages)

- Static brush (2 pages)

- H-Class Media Retainer (1 page)

- H-Class Thermal Transfer Option (12 pages)

- H-Class RFID Option (8 pages)

- H-Class Powered Internal Rewind Option (10 pages)

- H-Class Internal Rewind Option (6 pages)

- H-Class Present Sensor Option (8 pages)

- H-Class Peel & Present Option (8 pages)

- H-Class Linear Scanner Option (26 pages)

- H-Class HD Peel & Present Option (10 pages)

- H-Class HD Cutter Option (12 pages)

- H-Class GPIO Option (14 pages)

- H-Class Cutter Option (10 pages)