Inspection and maintenance of gas ports, Dx cooling, Figure 35 - removing piping scale with pin vise – AAON RL-240 User Manual

Page 55

55

4. Ensure that all vents to the atmosphere

are clean and free from obstruction.

5. Inspect and clean all drip legs in the gas

lines.

6. Inspect all electrical components,

connections and terminals. Clean and

tighten as necessary.

7. Clean ignition electrodes if necessary.

8. Put system back into operation and

observe the complete operation of the

burners through the full firing range.

There is an observation viewport

window in the gas piping compartment.

9. Observe the flame pattern and take any

necessary steps to correct any velocity

and/or air distribution problems.

10. Test the ignition spark and adjust gap if

necessary. Clean any carbon build-up on

ignition probes and troubleshoot for

cause.

11. Inspect all valves and piping for

operation and clean as necessary.

12. Inspect UV sensor observation window.

Clean any dust or debris present.

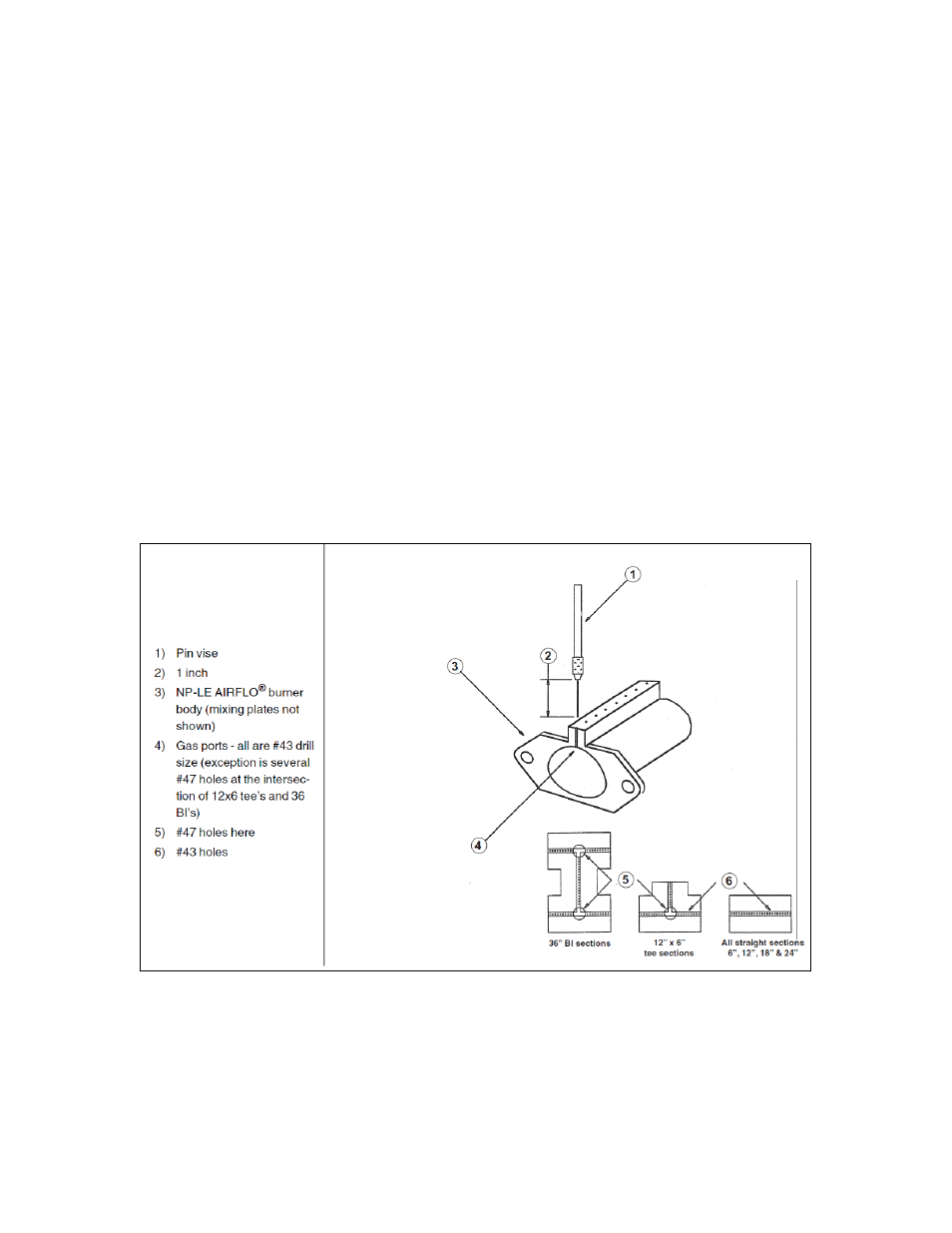

Inspection and Maintenance of Gas Ports:

1. Conduct an initial inspection within the

first month after commissioning.

Visually check the gas ports of new

burner assemblies for any piping scale or

debris. Use pin vise with drill bit to

remove (see below).

2. Annual inspections are normally

adequate once the initial piping debris is

removed. The operating conditions of

the burner will determine how frequently

the maintenance is actually required.

Figure 35 - Removing Piping Scale with Pin Vise

DX Cooling

Set unit controls to cooling mode of

operation with supply fans on. Check the

fans

for

correct

operating

direction,

amperage and voltage. Check compressor

operation, rotation, amperage and voltage to

the unit nameplate (check the amperage on

the load side of the compressor contactor).