Delta Controls 2HT User Manual

Page 6

002522-2HT 180210.doc

6

THE DISPLAY / CONFIGURATOR (“D_CAL”) :-

The Local display unit is constructed from a single stainless steel puck that when fitted gives the

transmitter a protection rating of IP 54 with the cover removed. The unit continuously shows prime

variable and units of measure in monitor mode. If current or percentage output is required, then this may

be selected on the D-CAL. The display unit also allows access to the state machine that generates a

user friendly menu with access to the internal HART® functions that are commonly used for installation

and maintenance.

To browse, edit and store information from the menu two buttons are used, CHANGE and SELECT. The

SELECT button, when held for 2 seconds, saves a selected value to EEPROM. If the selection is invalid

or out of range the transmitter will not store the change and will reply {REJECTED}.

For full detail, see the D-CAL Manual

INSTALLATION ( GENERAL )

The final accuracy of the transmitter depends to a great

extent on the proper installation of the unit and impulse

piping. Care should be taken to minimise the effects of

vibration, shock and temperature fluctuations. Care

should also be taken to make sure that the transmitter is

in a accessible position, where

possible.

Before installation of the unit, ensure that the pressure

range and maximum working pressures selected are

compatible with the expected system pressure. Adequate

lengths of impulse lines, or siphons should be used to

ensure that very high temperature process media do not

come into direct contact with the unit. Precautions should

also be taken against the media freezing within the unit.

As the best location for the transmitter in relation to the process depends upon the process medium,

please consider the following points before installation.

•

Keep all impulse lines as short as possible, and of the same length.

•

Avoid high points in liquid and low points in gas lines.

•

Use piping large enough to prevent blockage.

•

Make sure there are no unaccounted static heads that will give false readings.

•

Make sure that the transmitter is isolated from high process temperatures.

The 2HT is designed to be self supporting and can be mounted in any position. Brackets are, however,

available should wall or pipe mounting be required.

The pressure connection should be tightened using a 50 mm ( 2" ) AF spanner on the flats of the lower

body, and the appropriate spanner on the pipe-work connector.

DO NOT USE A COMPRESSION WRENCH ON THE 2HT BODY TO TIGHTEN THE PRESSURE

CONNECTION.

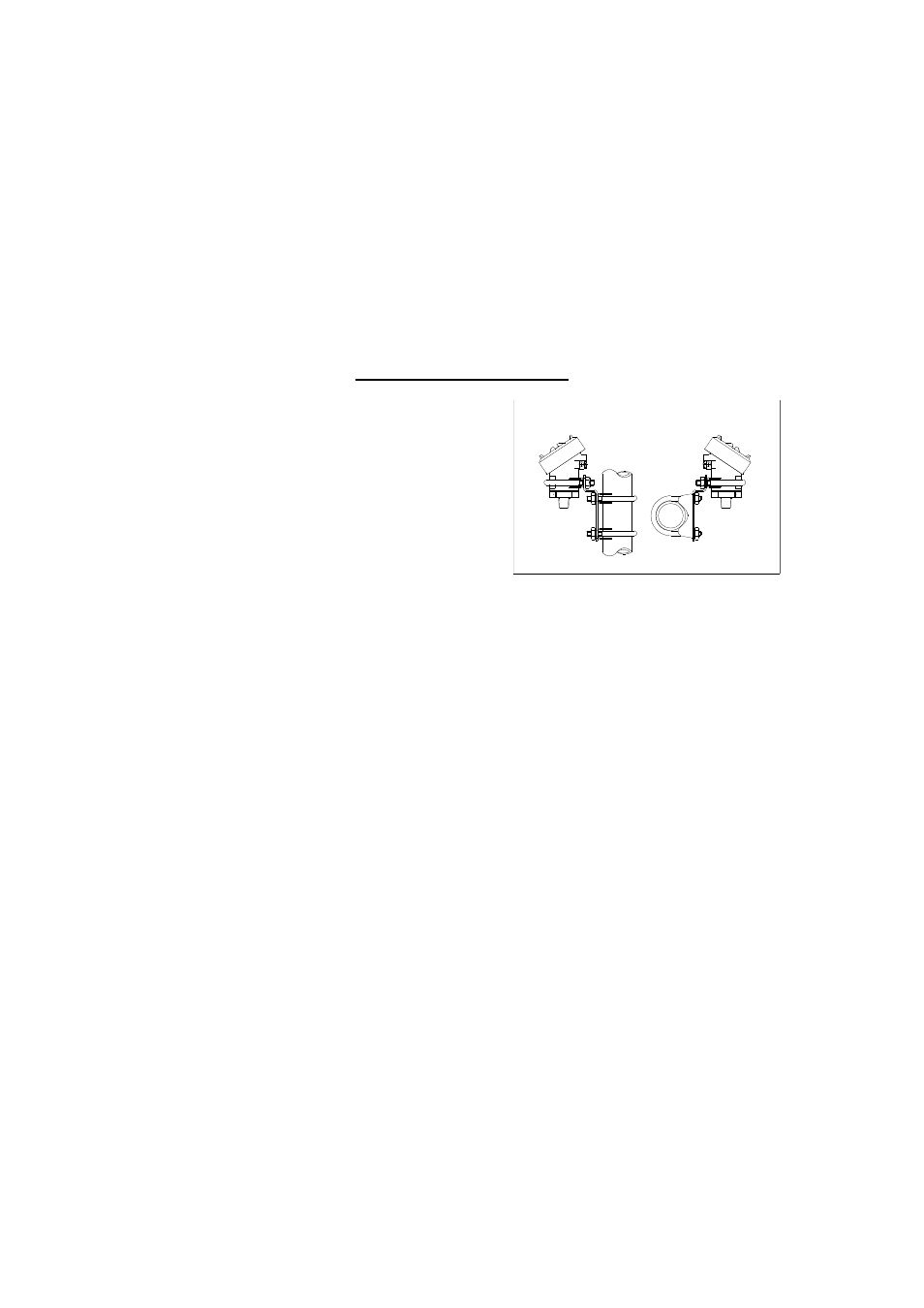

Typical Pipe Mounts for 2HT