CEMB USA C71 (A) User Manual

Page 18

I 293 - 18

GB

Err. 24

Distance between the spokes smaller

than 18 degrees.

1.

The minimum distance between the spokes where to split the

unbalance must be greater than 18 degrees

2. Repeat the SPLIT function increasing the distance between the

spokes.

Err. 25

Distance between the spokes greater

than 120 degree

1.

The minimum distance between the spokes where to split the

unbalance must be smaller than 120 degrees

2. Repeat the SPLIT function increasing the distance between the

spokes.

Err. 26

Distance between the fi rst selected spoke

and unbalance greater than 120°.

1.

To perform the SPLIT function correctly, the unbalance must be

inside two spokes no more than 120° apart.

2.

Repeat the SPLIT function selecting a spoke nearer the unbalance.

Err.32/

Err.33/

Err.34/

Err.35/

Err.36/

Err.37

Errors related to test functions of the wheel

balancer.

1.

Cancel the error and continue using the wheel balancer as normal.

7.1 - Inconsistent unbalance readings

It may occur that after balancing a wheel, when removing it from the wheel balancer and then remounting it, the

wheel is not balanced.

This is not the result of an incorrect indication by the machine, but only of incorrect mounting of the wheel on the

fl ange, i.e. in the two mountings the wheel has assumed a different position with respect to shaft axis of the wheel

balancer. If the wheel has been mounted on the fl ange with screws, it may be that the screws have not been tight-

ened correctly in gradual criss-cross manner one after the other, or (as often occurs) holes have been drilled in the

wheel with too wide tolerances.

Small errors, up to 10 grams (0.4 oz), are to be considered normal in wheels locked with a cone: the error is normally

greater for wheels locked with screws or studs.

If, after balancing, the wheel is still unbalanced when refi tted on the vehicle, this could be due to the unbalance of

the brake drum or very often is due to the screw holes in the rim and the drum drilled with too wide tolerances. In this

case a readjustment would be advisable using the wheel balancer with the wheel mounted.

8 - Routine maintenance

Before carrying out any operation on the machine, cut the power supply to the machine.

8.1 - Replacing the protection fuses

A protection fuse is fi tted on the power board, accessible by dismantling the weight shelf (see Exploded Drawings). If fuses

require replacement, use ones with an identical current rating.

If the fault persists, contact Technical Service.

NONE OF THE OTHER MACHINE PARTS REQUIRE MAINTENANCE

.

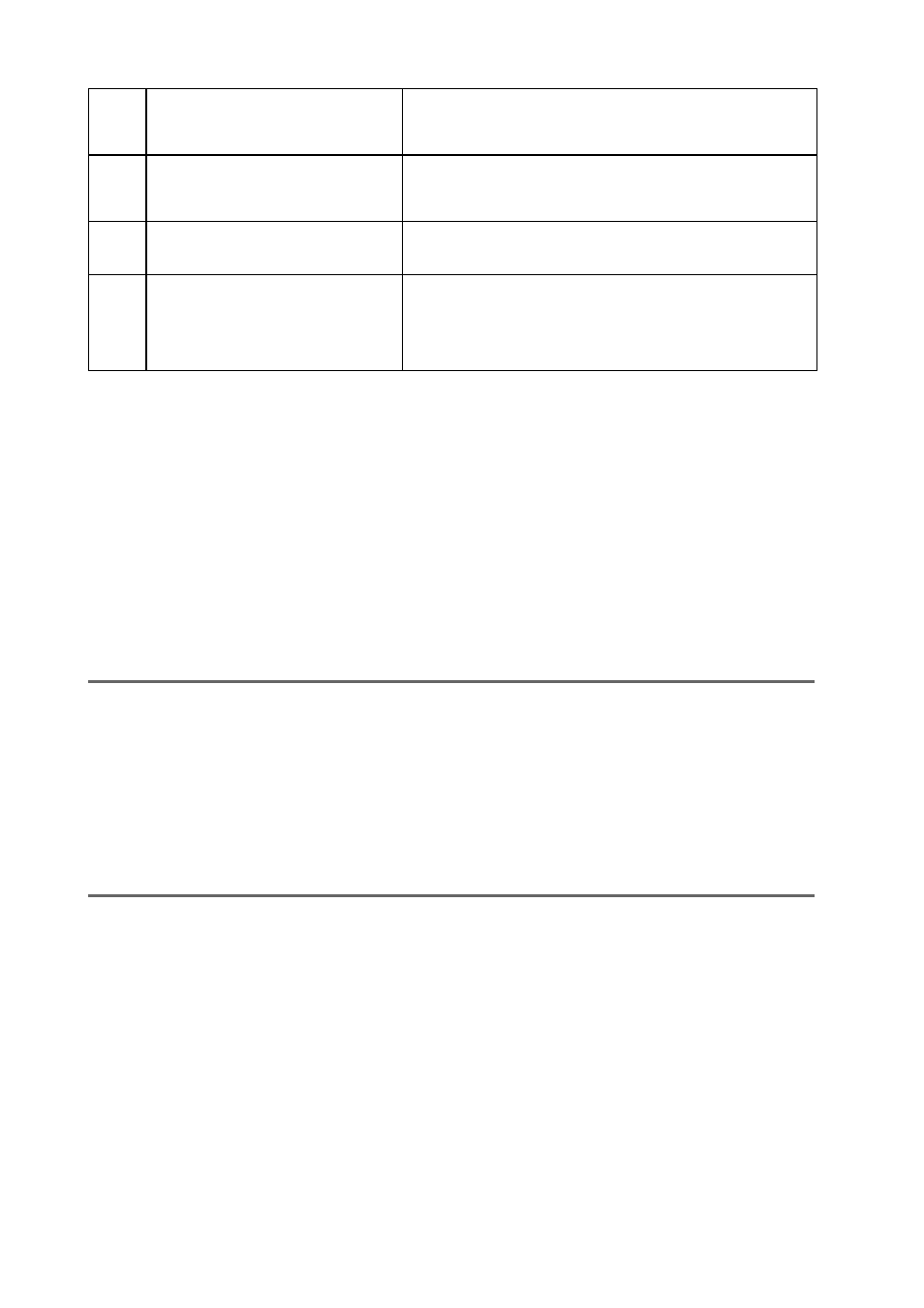

9 - List of recommended spare parts

(references on exploded drawings)

CODE

DESCRIPTION

181198630

Spring 19863P

67D59990A

Phase generator board with cable

05PR59195

LEXAN

Panel

182185750

Distance gauge spring

681002000

Fuse DM5x20 - 2A

511242101

Bipolar stub switch

86SC59755

Computer

board

86SB59758

Cable, automatic rim distance gauge

86SB59757

Cable, automatic diameter gauge

SPECIAL PARTS FOR 230V MACHINES

568007058

Capacitor 70MF 450V Faston screw M8

67M56989C

Power board

50FG58735

Stator 230V/50 - 60 Hz