5 automatic minimization of static unbalance, English – CEMB USA ER80 (D) User Manual

Page 14

14

sx

g

g

dx

50°

sx

g

g

dx

4 g

3 g

1 g

6 g

sx

g

g

dx

sx

g

g

dx

sx

g

g

dx

Use and maintenance manual Rev. 11-2012

ENGLISH

INfoRmATIoN

The spoke-to-spoke distance must be a minimum of

18° and a maximum of 120° (if not, errors 24,25,26 ap-

pear). Spokes with irregular or inconstant angles can be

compensated.

If the laser option is disabled (MENU), operate as fol-

lows:

▪ turn the wheel to the correction position of the unba-

lance to be split.

▪ move one of the spokes where you want to split the

unbalance to 12 o’clock (e.g. 1) and press

.

▪ Following the direction of rotation indicated by the

position LED’s, move spoke 2 to12 o’clock and press

. The value to use for correction in position 2 is

displayed

▪ position the wheel on spoke 1 following the LED indi-

cator and correct the unbalance as indicated on the

displays.

To return to the normal unbalance indication press

5.5 AUTOMATIC MINIMIZATION OF STATIC

UNBALANCE

This program is designed to improve the quality of balancing

without any mental effort or loss of time by the operator. In

fact by using the normal commercially available weights, with

pitch of 5 in every 5 g, and by applying the two counterweights

which a conventional wheel balancer rounds to the nearest

value, there could be a residual static unbalance of up to 4

g. The damage of such approximation is emphasized by the

fact that static unbalance is cause of most of disturbances

on the vehicle. This new function, resident in the machine,

automatically indicates the optimum entity of the weights

to be applied by approximating them in an “intelligent” way

according to their position in order to minimize residual static

unbalance.

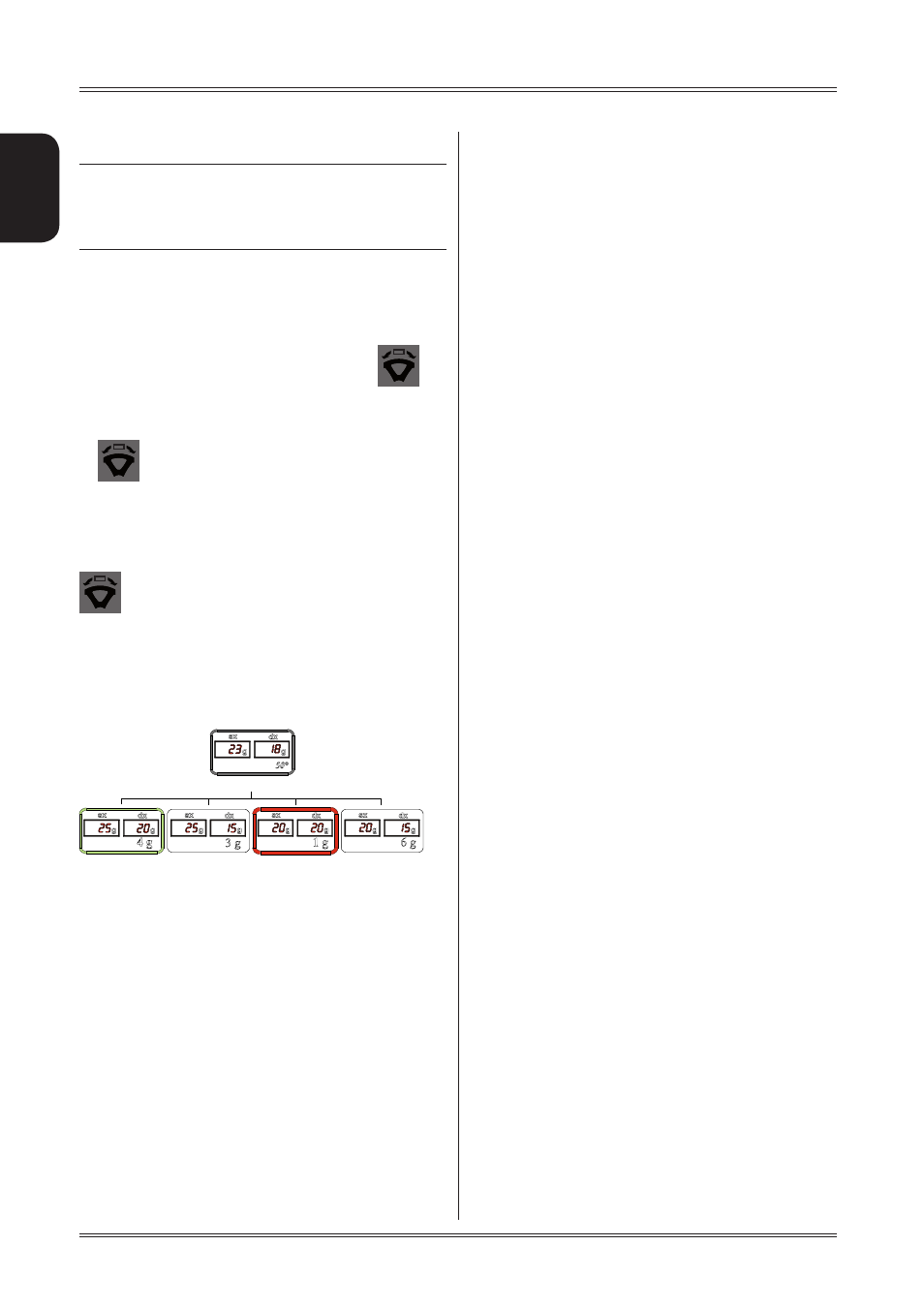

Initial unbalance

Phase shift

Possible approximations

static residue

static residue

static residue

static residue

With traditional wheel

balancer

Choice with minimum static

unbalance

Use of the wheel balancer