Maintenance, 1 general, 2 safety rules – CEMB USA C212 User Manual User Manual

Page 18: 3 replacing fuses, 4 to replace the driving pulley, English

18

Use and maintenance manual Rev. 10-2010

ENGLISH

Maintenance

8.1 GENERAL

cAuTIoN

b

efoRe

peRfoRmING

ANy

mAINTeNANce

opeRATIoNs

,

mAke

suRe

The

mAchINe

hAs

beeN

dIscoNNecTed

fRom

The

mAINs

poWeR

supply

. A

lWAys

use

The

p

eRsoNAl

p

RoTecTIve

e

quIpmeNT

INdIcATed

IN

The

I

NsTAllATIoN

m

ANuAl

.

8.1.1 Introductory notes

This machine has been designed so as not to require rou-

tine maintenance, apart from accurate periodic cleaning.

It is important to keep the machine perfectly clean in or-

der to prevent dust or impurities from compromising the

operation of the balancer.

WARNING

T

he

people

RespoNsIble

foR

cleANING

The

AReA

WheRe

The

mAchINe

Is

INsTAlled

musT

WeAR

peRsoNAl

pRoTecTIve

equIpmeNT

IN

oRdeR

To

WoRk

IN

sAfeTy

ANd

AccoRdING

To

The

cuRReNT

occupATIoNAl

heATh

ANd

sAfeTy

ReGulATIoNs

.

As extraordinary maintenance must be performed by service

staff or, in any case, by specifically authorised and trained

people, is not dealt with in this manual.

8.1.2 Safety rules

Performing specialist activities on the equipment, particu-

larly if the guards need to be dismounted, exposes people

to serious danger due to the presence of potentially live

parts.

The rules shown below must be scrupulously followed.

People must always use the Personal Protective Equip-

ment indicated in the Installation Manual. During activi-

ties, unauthorised people may not access the equipment

and WORK IN PROGRESS signs will be erected in the

department in such a way that they are visible from every

place of access.

8. Maintenance

Specialist staff must be authorised and especially trained

concerning the dangers that may arise during operation

and the correct methods for avoiding them.

They must always work with great care and pay full at-

tention.

If, exceptionally, the staff removes the guards to carry out

a particular specialist technical maintenance, inspection

or repair job, they are required to put them back after

work.

After work, staff must make sure that foreign objects, in

particular mechanical pieces, tools or devices used dur-

ing the operative procedure that could cause damage or

malfunctions are not left inside the balancer.

For safety, before starting work, maintenance, inspection

and repair staff must disconnect all power sources and

take all the necessary preventive safety measures.

As well as operating frequencies, the operations described

below indicate the qualifications that staff must possess

in order to perform the operation.

8.1.3 Replacing fuses

Some protection fuses are located on the power board

(see wiring diagrams) accessible by dismantling the weight

shelf). If fuses require replacement, use ones with an

identical current intensity.

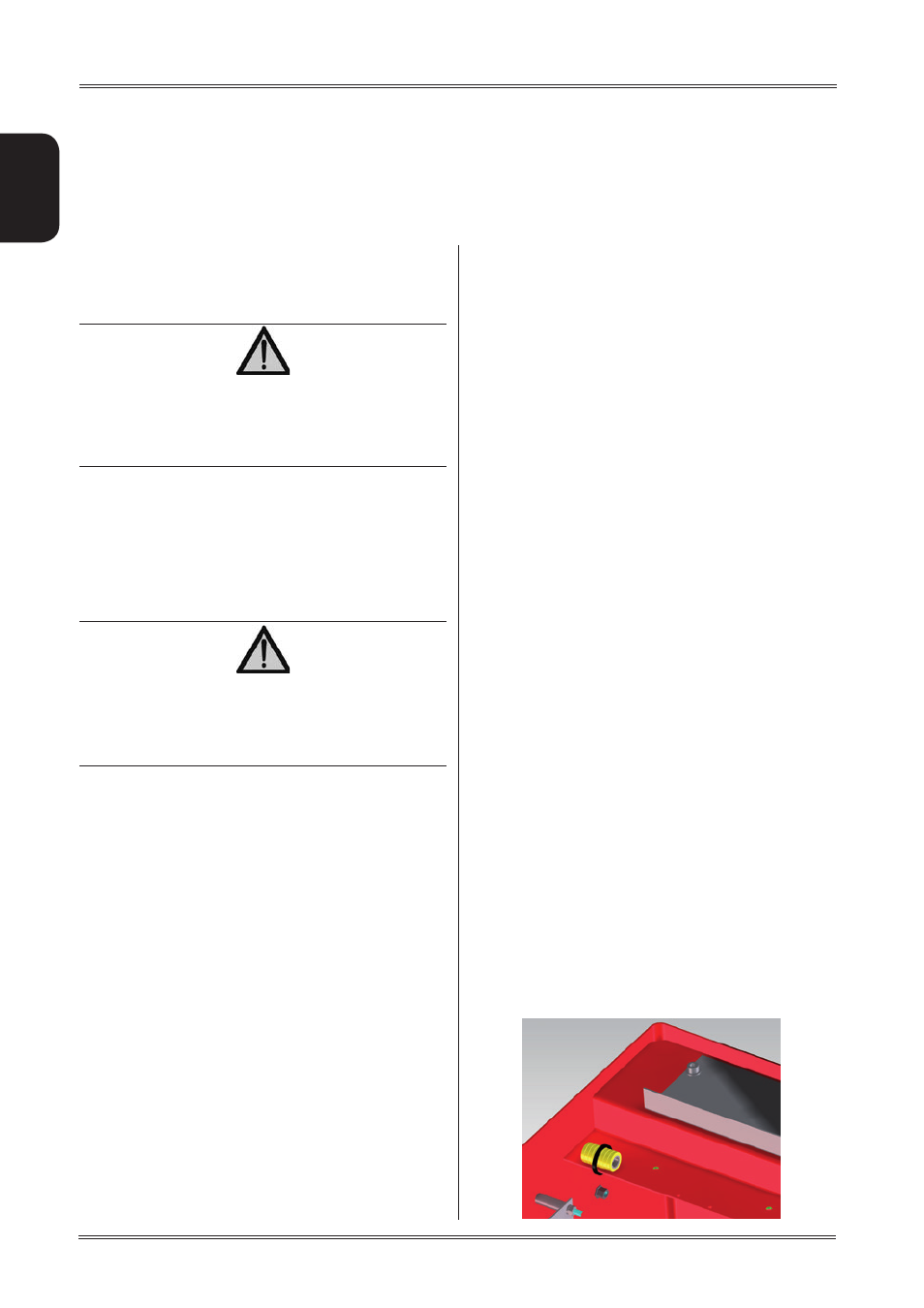

8.1.4 To replace the driving pulley

The drive pulley is guaranteed by the manufacturer for

approximately 20000 runs.

A spare pulley is found inside the base (see photograph).

If necessary, to replace the pulley, proceed as follows:

▪ Remove the head and the weight holder shelf, taking

care not to damage the electric wires

▪ Remove the retaining screw on the pulley in order to

replace it