API Delevan 4590 & 4590R User Manual

Series, High current filter inductors, Po w er i nd uc to rs

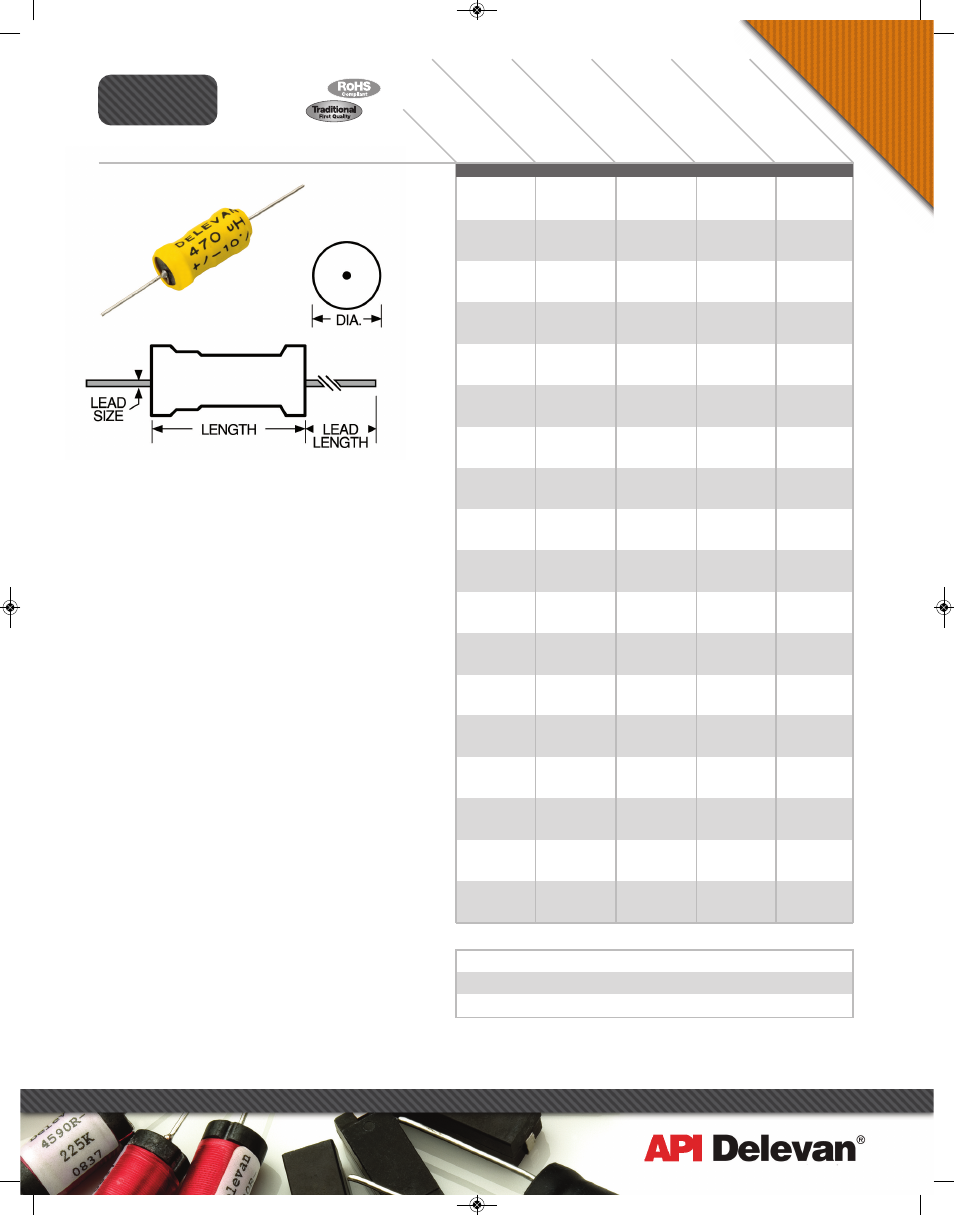

Actual Size (Max.)

DA

SH

NU

MB

ER

*

NO

MIN

AL

IN

DU

CT

AN

CE

(µH

) ±1

0%

CU

RR

EN

T R

AT

IN

G

MA

XIM

UM

(A

MP

S)

IN

CR

EM

EN

TA

L

CU

RR

EN

T D

C (A

MP

S)

DC

R

ES

IST

AN

CE

MA

XIM

UM

(O

HM

S)

SERIES

4590R

4590

High Current Filter Inductors

Physical Parameters

Inches Millimeters

Length 0.900 Max. 22.86 Max.

Diameter 0.455 Max. 11.55 Max.

Lead Size

AWG #20 TCW 0.032 ± 0.002 0.813 ± 0.05

Lead Length 1.10 Min. 27.94 Min.

Operating Temperature

–55°C to +125°C

–55°C to +85°C @ full rated current

Current Rating at 85°C Ambient 40°C Rise

Maximum Power Dissipation at 85°C 0.70 W

Dielectric Withstanding Voltage 2500 V RMS

Incremental Current The current which will decrease the

inductance by approximately 5%.

Inductance Measurement Inductance is measured @ 1 kHz

with 1 VAC open circuit and 0 dc bias.

Inductance Tolerance Tolerance is specified by suffixing an

alpha character to the part number as follows: J = 5%, K =

10%, and L = 15%. Units are normally supplied to the

tolerance indicated in table.

High Saturation Bobbin allows for high inductance

with low DCR.

High Resistivity Core offers very high parallel resistance,

resulting in maximum coil performance.

4590 Marking DELEVAN; inductance; tolerance.

4590R Marking DELEVAN; 4590R; dash number with

tolerance letter.

Example: 4590-393K

DELEVAN

39 uH

±10%

Example: 4590R-393K

DELEVAN

4590R

393K

Packaging Bulk only

Po

w

er I

nd

uc

to

rs

270 Quaker Rd., East Aurora NY 14052 • Phone 716-652-3600 • Fax 716-652-4814 • E-mail: [email protected] • www.delevan.com

SERIES 4590 FERRITE CORE

-392K

-472K

-562K

-682K

-822K

-103K

-123K

-153K

-183K

-223K

-273K

-333K

-393K

-473K

-563K

-683K

-823K

-104K

-124K

-154K

-184K

-224K

-274K

-334K

-394K

-474K

-564K

-684K

-824K

-105K

-125K

-155K

-185K

-225K

-275K

-335K

-395K

-475K

-565K

-685K

-825K

-106K

-126K

-156K

-186K

-226K

-276K

-336K

-396K

-476K

-566K

-686K

-826K

-107K

8.2

7.5

6.9

6.3

5.7

5.2

4.7

4.3

3.9

3.5

3.2

2.9

2.7

2.5

2.3

2.1

1.9

1.7

1.6

1.4

1.3

1.2

1.1

0.95

0.88

0.80

0.74

0.67

0.61

0.56

0.51

0.46

0.42

0.38

0.34

0.31

0.29

0.26

0.24

0.22

0.20

0.18

0.17

0.15

0.14

0.12

0.11

0.10

0.09

0.09

0.08

0.07

0.07

0.06

9.75

9.11

7.77

7.60

7.15

6.44

6.07

5.76

5.49

5.26

5.15

4.87

4.63

4.45

3.93

3.355

3.175

2.815

2.43

2.27

2.105

2.025

1.715

1.61

1.52

1.30

1.15

1.08

1.015

0.89

0.825

0.75

0.665

0.615

0.56

0.51

0.48

0.415

0.395

0.34

0.32

0.30

0.265

0.25

0.21

0.19

0.17

0.16

0.15

0.14

0.13

0.11

0.10

0.09

3.9

4.7

5.6

6.8

8.2

10.0

12.0

15.0

18.0

22.0

27.0

33.0

39.0

47.0

56.0

68.0

82.0

100

120

150

180

220

270

330

390

470

560

680

820

1000

1200

1500

1800

2200

2700

3300

3900

4700

5600

6800

8200

10000

12000

15000

18000

22000

27000

33000

39000

47000

56000

68000

82000

100000

0.007

0.008

0.011

0.011

0.013

0.016

0.018

0.020

0.022

0.024

0.025

0.028

0.031

0.034

0.043

0.059

0.066

0.084

0.113

0.129

0.150

0.162

0.226

0.257

0.288

0.393

0.504

0.570

0.643

0.844

0.977

1.18

1.50

1.76

2.13

2.53

2.84

3.79

4.24

5.75

6.44

7.30

9.34

10.7

14.8

18.0

22.7

25.7

29.7

33.7

38.0

52.8

67.3

76.0

Optional Tolerances: J = 5% L = 15%

*Complete part # must include series # PLUS the dash #

For surface finish information, refer to www.delevanfinishes.com

1/2009

API_newlayouts_single:APIcatalog_newlayouts 8/26/10 12:18 PM Page 95