API Delevan 3094 & 3094R User Manual

Series, Micro i, Chip inductors

Actual Size

SERIES

3094R

3094

Micro i

®

Chip Inductors

SR

F M

IN

IM

UM

(M

Hz

)

DA

SH

NU

MB

ER

*

MIL

D

AS

H #

(R

efe

ren

ce)

Q M

IN

IM

UM

TE

ST

FR

EQ

UE

NC

Y (M

Hz

)

DC

R

ES

IST

AN

CE

MA

XIM

UM

(O

HM

S)

CU

RR

EN

T R

AT

IN

G

MA

XIM

UM

(m

A)

IN

DU

CT

AN

CE

(µ

H) ±

10%

R

F I

nd

uc

to

rs

270 Quaker Rd., East Aurora NY 14052 • Phone 716-652-3600 • Fax 716-652-4814 • E-mail: [email protected] • www.delevan.com

M83446/10– (Reference) SERIES 3094 IRON CORE

-100KS

-120KS

-150KS

-180KS

-220KS

-270KS

-330KS

-390KS

-470KS

-560KS

-680KS

-820KS

-101KS

-121KS

-151KS

-181KS

-221KS

-271KS

-331KS

-391KS

-471KS

-561KS

-681KS

-821KS

-102KS

-122KS

-152KS

-182KS

-222KS

-272KS

-332KS

-392KS

-472KS

-562KS

-682KS

-822KS

-103KS

-123KS

-153KS

-183KS

-223KS

-273KS

-333KS

-393KS

-473KS

-563KS

-683KS

-823KS

-104KS

-124KS

-154KS

-184KS

-224KS

-274KS

-334KS

-394KS

-474KS

-564KS

-684KS

-824KS

-105KS

1000

1000

1000

1000

1000

1000

1000

900

900

900

840

840

840

840

790

790

790

700

700

700

590

510

430

400

380

330

290

260

230

210

200

180

170

160

140

130

120

118

115

114

113

110

100

84

79

70

67

64

62

59

56

52

45

44

41

39

37

33

30

26

25

0.040

0.040

0.040

0.040

0.050

0.050

0.050

0.060

0.060

0.060

0.070

0.070

0.070

0.070

0.080

0.080

0.080

0.10

0.10

0.10

0.14

0.19

0.26

0.30

0.34

0.45

0.57

0.72

0.90

1.10

1.20

1.40

1.60

1.80

2.40

3.00

3.50

3.60

3.70

3.80

3.90

4.00

5.00

7.00

8.00

10.0

11.0

12.0

13.0

14.0

16.0

18.0

24.0

25.0

29.0

32.0

35.0

45.0

55.0

70.0

80.0

2000.0

1800.0

1500.0

1500.0

1300.0

1300.0

1000.0

1000.0

800.0

760.0

700.0

650.0

570.0

520.0

400.0

360.0

320.0

270.0

240.0

220.0

190.0

170.0

160.0

150.0

130.0

120.0

110.0

100.0

80.0

60.0

50.0

45.0

42.0

40.0

37.0

34.0

29.0

27.0

22.0

17.0

16.0

15.0

14.0

13.0

12.0

11.0

10.0

9.0

8.0

7.0

6.0

5.0

4.0

3.3

3.1

2.9

2.4

2.1

1.9

1.8

1.7

150

150

150

150

100

100

100

100

100

100

100

100

50

50

50

50

50

50

50

50

25

25

25

25

25

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

0.79

0.79

0.79

0.79

0.79

0.79

0.79

0.79

0.79

0.79

0.79

0.79

60

60

60

60

60

60

60

60

65

65

65

65

65

65

75

75

70

70

70

70

70

70

70

75

75

65

65

65

65

65

60

60

60

65

65

65

65

60

60

60

60

65

65

65

70

70

65

60

60

40

40

40

40

40

40

40

35

35

35

30

30

0.010

0.012

0.015

0.018

0.022

0.027

0.033

0.039

0.047

0.056

0.068

0.082

0.100

0.120

0.150

0.180

0.220

0.270

0.330

0.390

0.470

0.560

0.680

0.820

1.00

1.20

1.50

1.80

2.20

2.70

3.30

3.90

4.70

5.60

6.80

8.20

10.0

12.0

15.0

18.0

22.0

27.0

33.0

39.0

47.0

56.0

68.0

82.0

100.0

120.0

150.0

180.0

220.0

270.0

330.0

390.0

470.0

560.0

680.0

820.0

1000.0

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

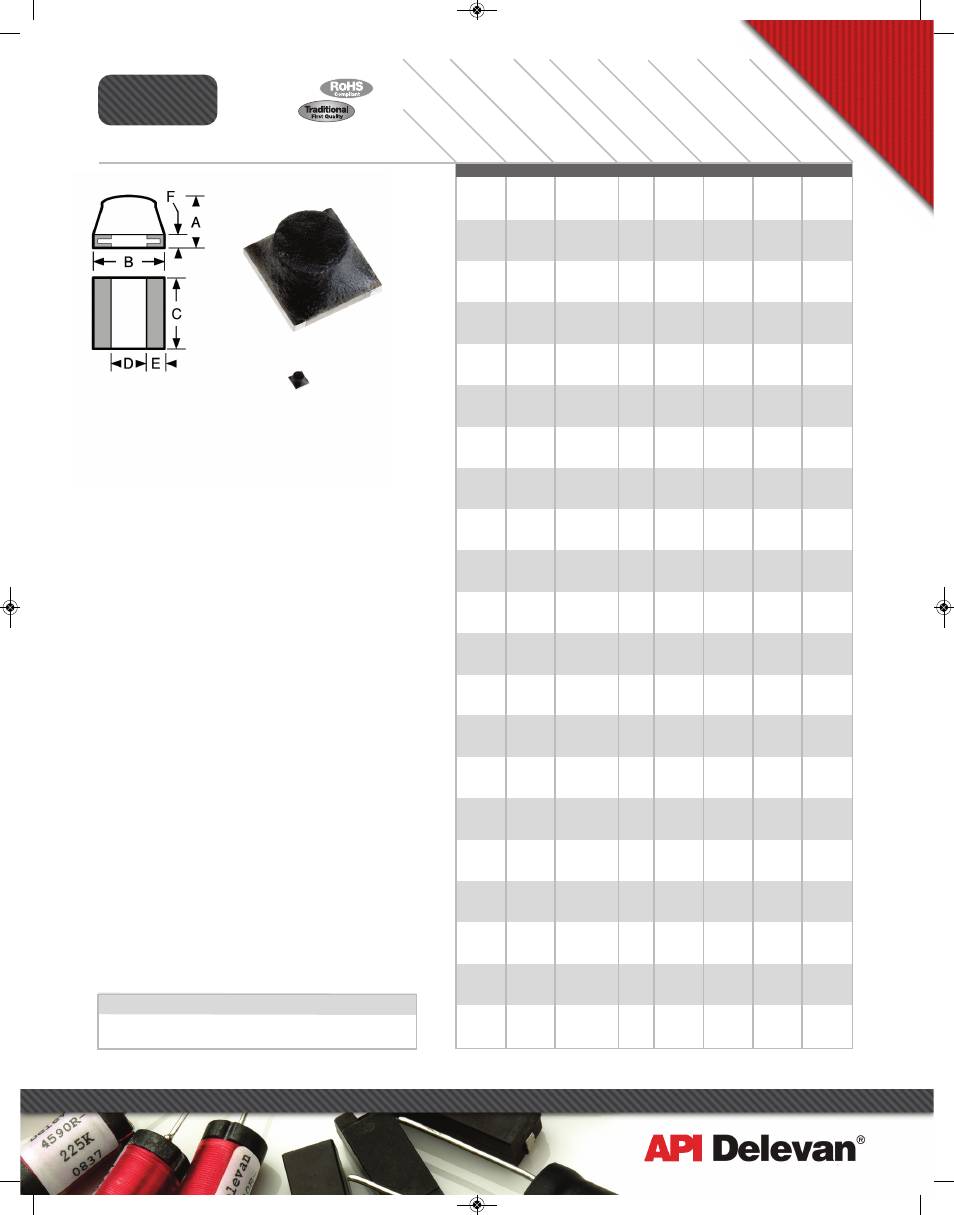

Physical Parameters

Inches Millimeters

A 0.140 Max. 3.56 Max.

B 0.147 to 0.163 3.73 to 4.14

C 0.117 to 0.133 2.97 to 3.38

D 0.070 Min. 1.78 Min.

E 0.017 to 0.033 0.43 to 0.84

F 0.020 Max. (Typ.) 0.51 Max. (Typ.)

Current Rating at 90°C Ambient 35°C Rise

Operating Temperature Range –55°C to +125°C

Maximum Power Dissipation at 90°C 0.155 W

Inductance tolerance desired is specified by suffixing

an alpha character to the part number: F = 1%, G = 2%,

H = 3%, J = 5%, K = 10%, and M = 20%. Standard

series tolerance is ±10%. For inductance values less

than .10µH, minimum tolerance is ±5%.

Termination Standard: Tin/Lead Sn63

Mechanical Configuration Units are epoxy

encapsulated. Contact area for reflow are solder coated.

Internal connections are thermal compression bonded.

Notes 1) Designed specifically for reflow soldering and

other high temperature processes with metalized edges to

exhibit solder fillet.

2) Self Resonant Frequency (SRF)

values 270 MHz and above are calculated and for

reference only.

3) Optional marking is available.

Packaging Tape & reel (12mm): 7" reel, 650 pieces max.;

13" reel, 2500 pieces max.

MIL-PRF-83446/10 (Reference)

Made In the U.S.A.

*Complete part # must include series # PLUS the dash #

For surface finish information,

refer to www.delevanfinishes.com

1/2009

API_newlayouts_single:APIcatalog_newlayouts 7/23/10 10:02 AM Page 12