API Delevan 3090 & 3090R User Manual

Series, Micro i, Low profile chip inductors

Actual Size

SERIES

3090R

3090

Micro i

®

Low Profile Chip Inductors

SR

F M

IN

IM

UM

(M

Hz

)

DA

SH

NU

MB

ER

*

IN

DU

CT

AN

CE

(µ

H)

Q M

IN

IM

UM

TE

ST

FR

EQ

UE

NC

Y (M

Hz

)

DC

R

ES

IST

AN

CE

MA

XIM

UM

(O

HM

S)

CU

RR

EN

T R

AT

IN

G

MA

XIM

UM

(m

A)

TO

LE

RA

NC

E

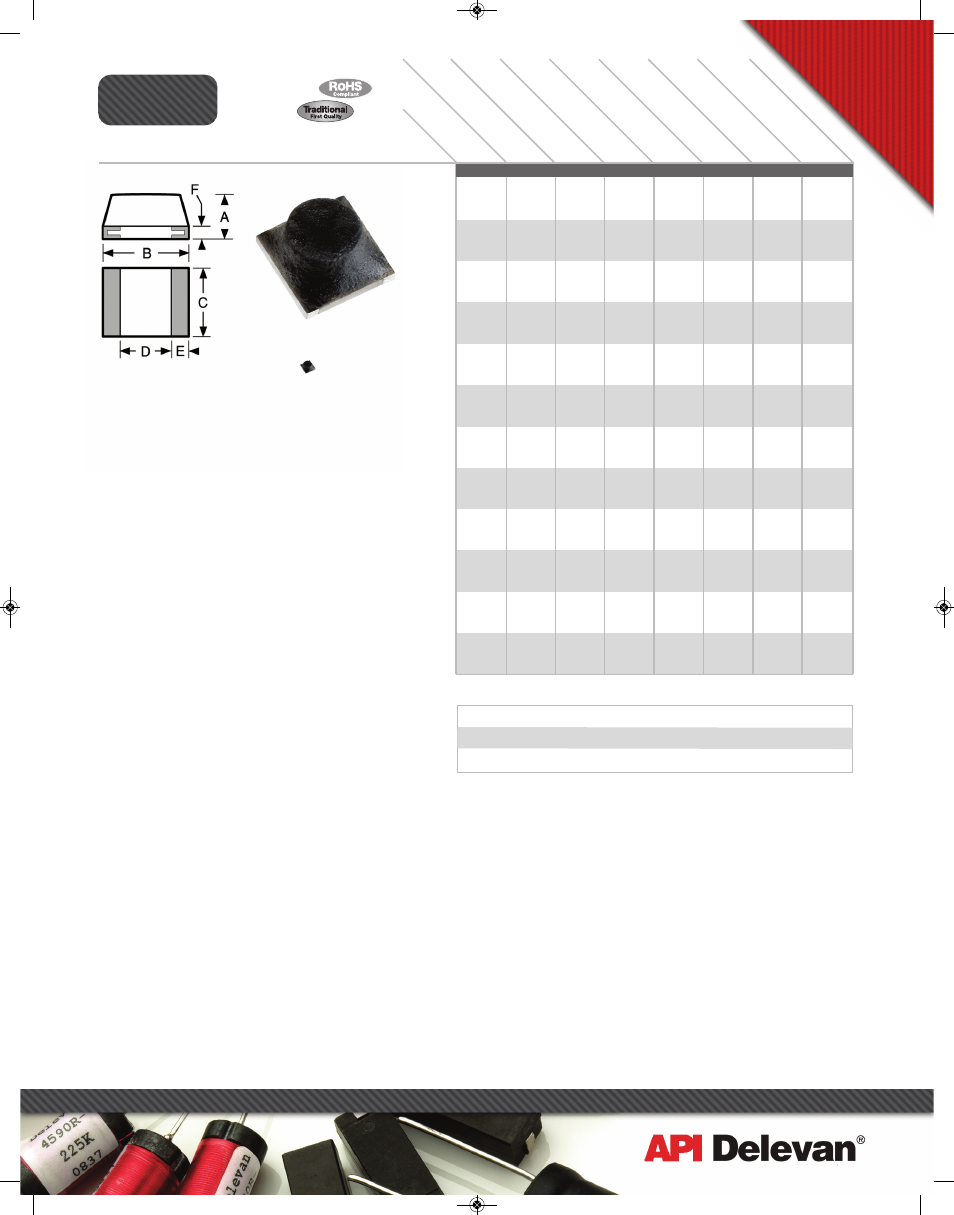

Physical Parameters

Inches Millimeters

A 0.050 Max. 1.27 Max.

B 0.100±0.010 2.54±0.254

C 0.100±0.010 2.54±0.254

D 0.050 Min. 1.27 Min.

E 0.015 Min. (Typ.) 0.38 Min. (Typ.)

F 0.020 Max. (Typ.) 0.51 Max. (Typ.)

Current Rating at 90°C Ambient 35°C Rise

Operating Temperature Range –55°C to +125°C

Maximum Power Dissipation at 90°C 0.105 W

Core Material Powdered iron core for improved

temperature stability.

Mechanical Configuration Units are epoxy

encapsulated. Contact area for reflow soldering are gold

plated per MIL-G-45204 Type 1 Grade A. Internal

connections are thermal compression bonded.

Termination Finish Options

Standard: Gold over Nickel.

For Tin/Lead over Nickel: Add suffix “S” to part number and

allow an additional .010 inch for maximum height. For

RoHS, order 3090R - XXXKS.

Notes 1) Designed specifically for reflow soldering and

other high temperature processes with metalized edges to

exhibit solder fillet.

2) Self Resonant Frequency (SRF)

values 250 MHz and above are calculated and for

reference only.

Packaging Tape & reel (8mm): 7" reel, 2000 pieces max.;

13" reel, 8000 pieces max.

MIL-PRF-83446 (Reference) for testing methods only.

Made in the U.S.A.

SERIES 3090 IRON CORE

-100M

-150M

-220M

-330K

-390K

-470K

-560K

-680K

-820K

-101K

-121K

-151K

-181K

-221K

-271K

-331K

-391K

-471K

-561K

-681K

-821K

-102K

-122K

-152K

-182K

-222K

-272K

-332K

-392K

-472K

-562K

-682K

-822K

-103K

R

F I

nd

uc

to

rs

270 Quaker Rd., East Aurora NY 14052 • Phone 716-652-3600 • Fax 716-652-4814 • E-mail: [email protected] • www.delevan.com

890

810

765

640

870

830

750

690

630

970

870

795

765

690

615

550

500

460

410

390

355

330

265

250

245

240

225

200

180

160

145

135

130

120

0.095

0.115

0.140

0.185

0.100

0.110

0.135

0.16

0.19

0.08

0.10

0.12

0.14

0.16

0.20

0.25

0.30

0.36

0.45

0.50

0.60

0.70

1.10

1.20

1.25

1.30

1.50

1.90

2.30

3.00

3.50

4.00

4.50

5.00

1000

1000

1000

900

900

900

800

700

650

510

410

370

330

300

250

220

200

180

160

140

120

100

95

90

85

80

70

65

60

55

53

50

45

40

50.0

50.0

50.0

50.0

50.0

50.0

50.0

50.0

50.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

42

42

40

40

40

38

35

30

25

32

32

32

32

34

34

34

34

34

34

30

28

24

24

24

24

25

25

25

25

24

22

22

22

20

± 20%

± 20%

± 20%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

0.010

0.015

0.022

0.033

0.039

0.047

0.056

0.068

0.082

0.10

0.12

0.15

0.18

0.22

0.27

0.33

0.39

0.47

0.56

0.68

0.82

1.00

1.20

1.50

1.80

2.20

2.70

3.30

3.90

4.70

5.60

6.80

8.20

10.0

Optional Tolerances: J = 5% H = 3% G = 2% F = 1%

*Complete part # must include series # PLUS the dash #

For surface finish information, refer to www.delevanfinishes.com

1/2009

API_newlayouts_single:APIcatalog_newlayouts 7/22/10 10:25 AM Page 11