API Delevan 1330 & 1330R User Manual

Series, Unshielded surface mount inductors, Rf i nd uc to rs

Actual Size

SR

F M

IN

IM

UM

(M

Hz

)

DA

SH

NU

MB

ER

*

IN

DU

CT

AN

CE

(µ

H) ±

10%

Q M

IN

IM

UM

TE

ST

FR

EQ

UE

NC

Y (M

Hz

)

DC

R

ES

IST

AN

CE

MA

XIM

UM

(O

HM

S)

CU

RR

EN

T R

AT

IN

G

MA

XIM

UM

(m

A)

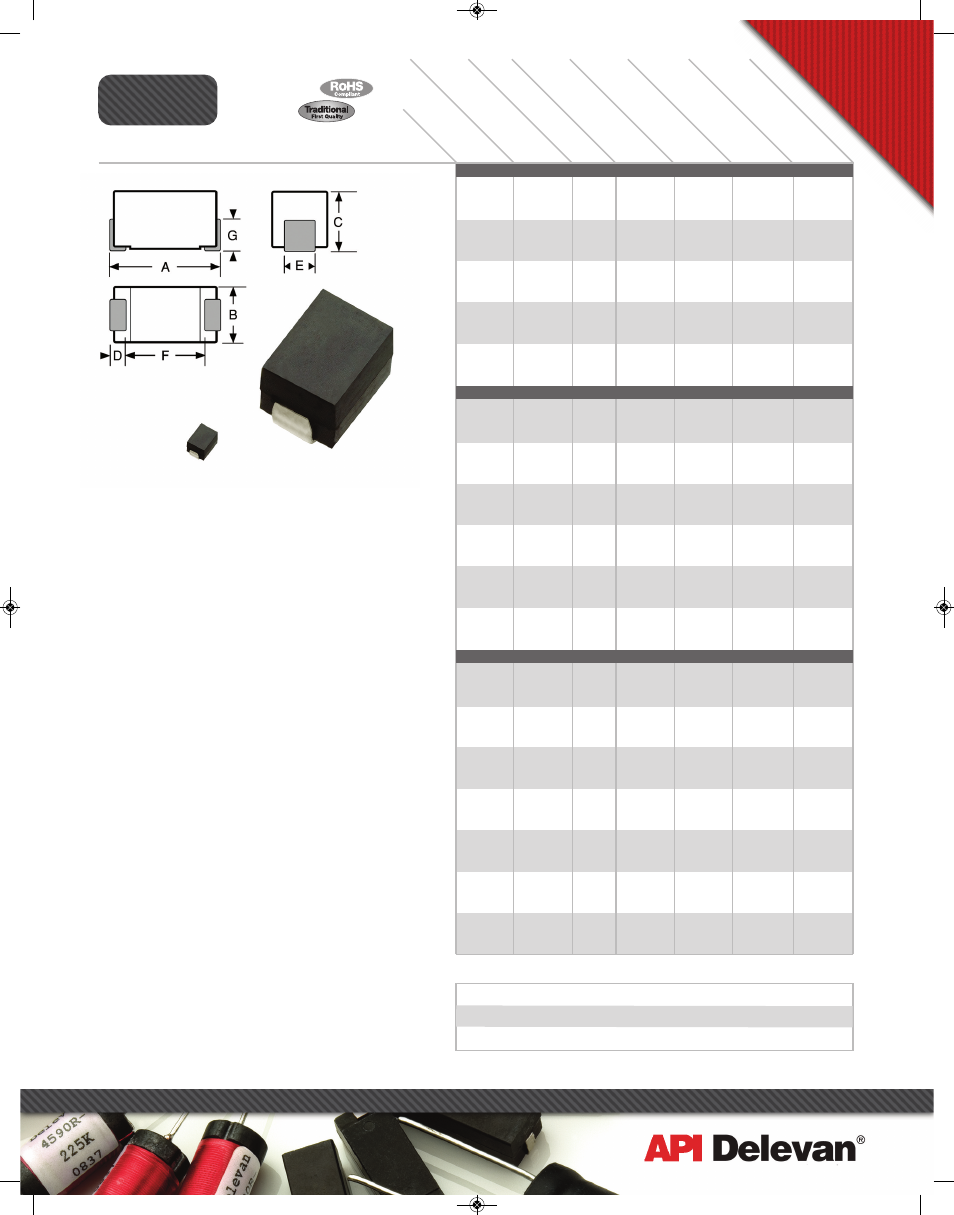

SERIES

1330R

1330

Unshielded Surface Mount Inductors

Physical Parameters

Inches Millimeters

A 0.300 to 0.325 7.62 to 8.26

B 0.105 to 0.125 2.67 to 3.18

C 0.125 to 0.145 3.18 to 3.68

D 0.020 Min. 0.508 Min.

E 0.040 to 0.060 1.02 to 1.52

F 0.190 (Ref. only) 4.83 (Ref. only)

G 0.070 (Ref. only) 1.78 (Ref. only)

Weight Max (Grams) 0.30

Operating Temperature Range

Phenolic: –55°C to +125°C

Iron and Ferrite: –55°C to +105°C

Current Rating at 90°C Ambient

Phenolic: 35°C Rise

Iron and Ferrite: 15°C Rise

Maximum Power Dissipation at 90°C Ambient

Phenolic: 0.210 W

Iron: 0.090 W

Ferrite: 0.073 W

Marking API/SMD; inductance with units and tolerance;

date code (YYWWL). Note: An R before the date code

indicates a RoHS component.

Example: 1330-42K

API/SMD

8.2uH±10%

0218A

Packaging Tape & reel (16mm): 7" reel, 500 pieces max.;

13" reel, 2200 pieces max.

Made In the U.S.A.

R

F I

nd

uc

to

rs

270 Quaker Rd., East Aurora NY 14052 • Phone 716-652-3600 • Fax 716-652-4814 • E-mail: [email protected] • www.delevan.com

SERIES 1330 PHENOLIC CORE

-94K

-96K

-00K

-02K

-04K

-06K

-08K

-10K

-12K

-14K

-16K

-18K

-20K

SERIES 1330 IRON CORE

-22K

-24K

-26K

-28K

-30K

-32K

-34K

-36K

-38K

-40K

-42K

-44K

-46K

-48K

-50K

-52K

-54K

SERIES 1330 FERRITE CORE

-56K

-58K

-60K

-62K

-64K

-66K

-68K

-70K

-72K

-74K

-76K

-78K

-80K

-82K

-84K

-86K

-88K

-90K

-92K

1380

1300

1230

1120

1040

975

830

710

660

550

500

420

390

620

560

480

415

355

285

263

239

195

185

160

144

160

157

149

144

140

130

125

110

100

92

88

84

66

61

57

52

47

45

40

36

35

30

29

28

0.08

0.09

0.10

0.12

0.14

0.16

0.22

0.30

0.35

0.50

0.60

0.85

1.00

0.18

0.22

0.30

0.40

0.55

0.85

1.00

1.20

1.80

2.00

2.70

3.30

2.70

2.80

3.10

3.30

3.50

3.40

3.60

4.50

5.70

6.70

7.30

8.00

13.00

15.00

17.00

21.00

25.00

28.00

35.00

42.00

46.00

60.00

65.00

72.00

680.0

640.0

600.0

550.0

510.0

430.0

410.0

365.0

330.0

300.0

275.0

250.0

230.0

150.0

140.0

125.0

115.0

100.0

90.0

80.0

75.0

65.0

60.0

55.0

50.0

40.0

35.0

30.0

25.0

20.0

24.0

22.0

20.0

18.0

15.0

14.0

13.0

12.0

11.0

10.0

9.0

8.0

7.0

6.5

6.0

5.0

4.2

3.8

3.4

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

0.79

0.79

0.79

0.79

0.79

0.79

0.79

0.79

0.79

0.79

0.79

0.79

40

40

38

35

33

33

30

30

30

30

28

28

25

25

28

30

30

37

45

45

45

50

50

55

55

45

45

45

45

45

35

35

35

35

35

35

35

30

30

30

30

30

30

30

30

30

30

30

30

0.10

0.12

0.15

0.18

0.22

0.27

0.33

0.39

0.47

0.56

0.68

0.82

1.00

1.20

1.50

1.80

2.20

2.70

3.30

3.90

4.70

5.60

6.80

8.20

10.00

12.0

15.0

18.0

22.0

27.0

33.0

39.0

47.0

56.0

68.0

82.0

100.0

120.0

150.0

180.0

220.0

270.0

330.0

390.0

470.0

560.0

680.0

820.0

1000.0

Optional Tolerances: J = 5% H = 3% G = 2% F = 1%

*Complete part # must include series # PLUS the dash #

For surface finish information, refer to www.delevanfinishes.com

1/2009

API_newlayouts_single:APIcatalog_newlayouts 8/27/10 3:19 PM Page 21