API Delevan 108 & 108R User Manual

Series, Micro i, Chip inductors

Actual Size

Military Specifications

Series 105 MIL-PRF-83446 (Reference)

Series 108 MIL-PRF-83446/8 (Reference)

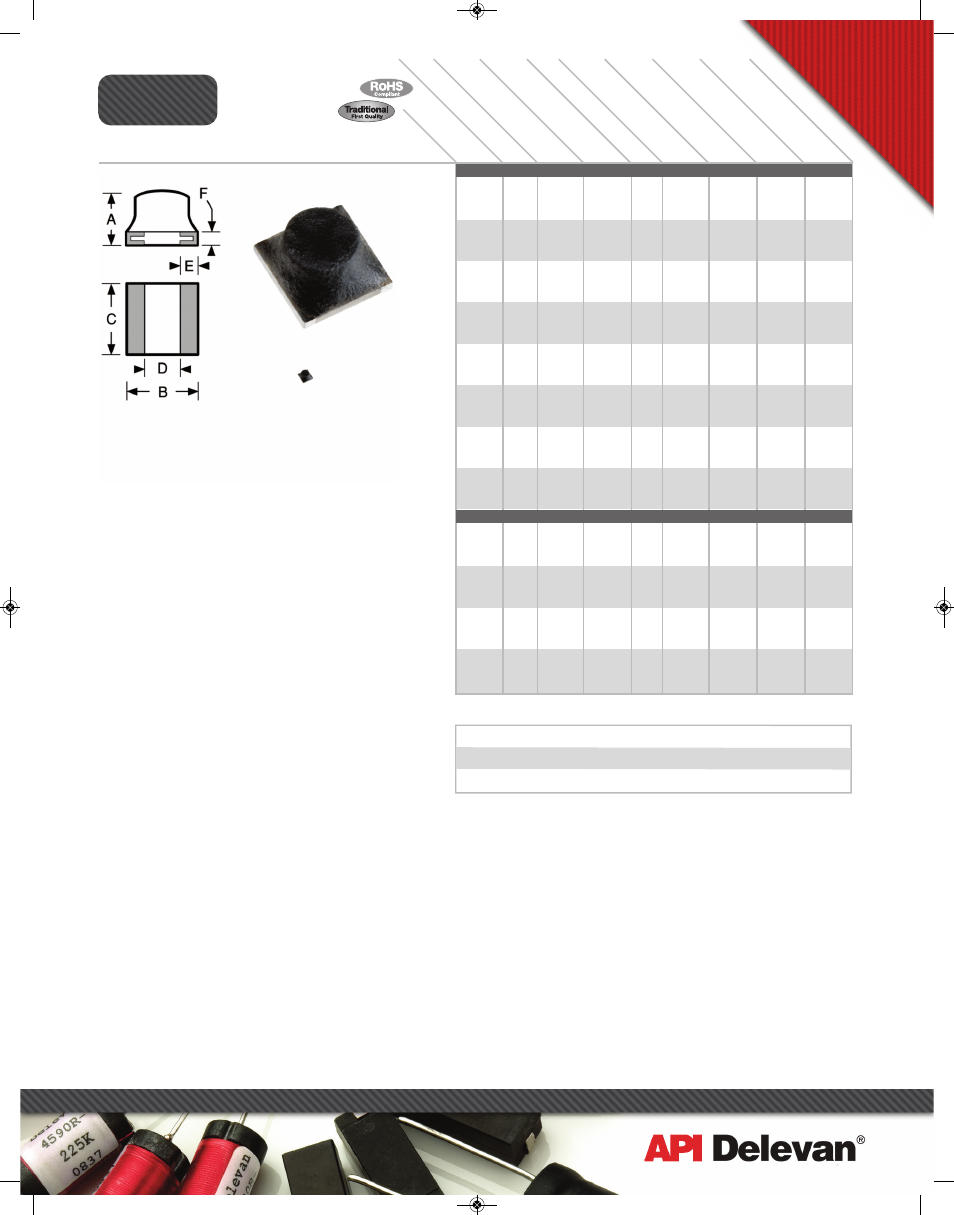

Physical Parameters for Series 105

Inches Millimeters

A 0.075 Max. 1.91 Max.

B 0.100 ± 0.010 2.54 ± 0.25

C 0.100 ± 0.010 2.54 ± 0.25

D 0.050 Min. 1.27 Min.

E 0.015 Min. (Typ.) 0.38 Min. (Typ.)

F 0.020 Max. (Typ.) 0.51 Max. (Typ.)

Physical Parameters for Series 108

Inches Millimeters

A 0.070 Max. 1.78 Max.

B 0.100 ± 0.010 2.54 ± 0.254

C 0.100 ± 0.010 2.54 ± 0.254

D 0.050 Min. 1.27 Min.

E 0.025 ± 0.005 (Typ.)0.635 ± 0.13 (Typ.)

F 0.020 Max. (Typ.) 0.51 Max. (Typ.)

Weight Max. (Grams) 0.05

Current Rating at 90°C Ambient 35°C Rise

Operating Temperature Range –55°C to +125°C

Maximum Power Dissipation at 90°C 0.135 W

Mechanical Configuration Units are epoxy

encapsulated. Contact areas for reflow soldering are gold

plated per MIL-G-45204 Type 1-Grade A. Internal

connections are thermal compression bonded.

Packaging Tape & reel (8mm): 7" reel, 2000 pieces max.;

13" reel, 8000 pieces max.

Made in the U.S.A.

MIL

DA

SH

# (

Re

fere

nce

)

SERIES

105R & 108R

105 & 108

Micro i

®

Chip Inductors

SR

F M

IN

IM

UM

(M

Hz

)

DA

SH

NU

MB

ER

*

IN

DU

CT

AN

CE

(µ

H)

Q M

IN

IM

UM

TE

ST

FR

EQ

UE

NC

Y (M

Hz

)

DC

R

ES

IST

AN

CE

MA

XIM

UM

(O

HM

S)

CU

RR

EN

T R

AT

IN

G

MA

XIM

UM

(m

A)

TO

LE

RA

NC

E

R

F I

nd

uc

to

rs

270 Quaker Rd., East Aurora NY 14052 • Phone 716-652-3600 • Fax 716-652-4814 • E-mail: [email protected] • www.delevan.com

SERIES 105 IRON CORE

-121M

-151M

-181M

-221K

-271K

-331K

-391K

-471K

-561K

-681K

-821K

-102K

-122K

-152K

-182K

-222K

-272K

-332K

-392K

-472K

-562K

-682K

-822K

-103K

M83446/08– (Reference) SERIES 108 IRON CORE

-123K

-153K

-183K

-223K

-273K

-333K

-393K

-473K

-563K

-683K

-823K

-104K

0.14

0.16

0.19

0.21

0.23

0.25

0.28

0.31

0.45

0.62

0.65

0.73

1.0

1.2

1.5

1.7

2.0

2.2

2.8

3.1

3.3

3.8

5.0

5.6

4.0

4.2

4.4

7.5

8.0

13.0

17.0

19.0

23.0

25.0

28.0

31.0

830

775

710

675

650

620

585

555

460

395

385

360

310

280

250

235

220

210

185

175

170

160

135

130

79

79

75

57

55

45

38

36

33

32

30

28

500

440

405

360

330

280

185

178

163

160

155

130

115

100

90

75

68

62

57

52

47

42

40

38

26.0

24.0

21.0

19.0

14.0

12.0

10.0

9.0

8.5

8.2

8.0

7.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

25.0

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

7.9

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2.5

40

40

40

40

40

35

35

35

35

35

30

30

25

25

25

25

25

25

25

30

30

30

30

30

36

32

32

32

32

30

30

30

30

30

30

30

± 20%

± 20%

± 20%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

± 10%

0.12

0.15

0.18

0.22

0.27

0.33

0.39

0.47

0.56

0.68

0.82

1.0

1.2

1.5

1.8

2.2

2.7

3.3

3.9

4.7

5.6

6.8

8.2

10.0

12.0

15.0

18.0

22.0

27.0

33.0

39.0

47.0

56.0

68.0

82.0

100.0

87

88

89

90

91

92

93

94

95

96

97

98

Optional Tolerances: J = 5% H = 3% G = 2% F = 1%

*Complete part # must include series # PLUS the dash #

For surface finish information, refer to www.delevanfinishes.com

1/2009

API_newlayouts_single:APIcatalog_newlayouts 7/22/10 10:23 AM Page 8