API Delevan 2474 & 2474R User Manual

Series, Axial lead power inductors, Po w er i nd uc to rs

Actual Size

DA

SH

NU

MB

ER

*

IN

DU

CT

AN

CE

@

1 k

Hz

(µH

) ±1

5%

CU

RR

EN

T R

AT

IN

G

MA

XIM

UM

(A

MP

S)

IN

CR

EM

EN

TA

L

CU

RR

EN

T (A

MP

S)

DC

R

ES

IST

AN

CE

MA

XIM

UM

(O

HM

S)

SERIES

2474R

2474

Axial Lead Power Inductors

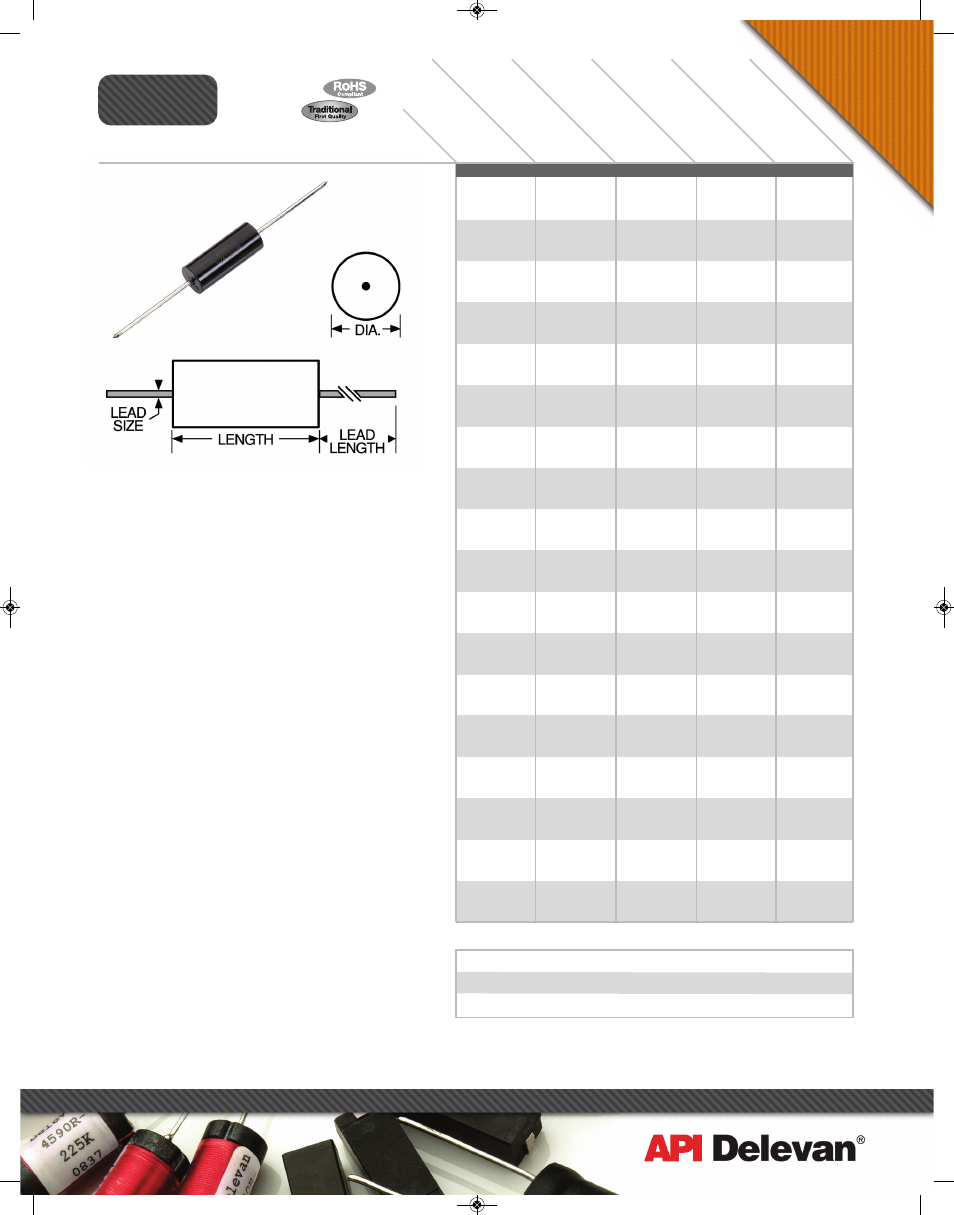

Mechanical Configuration Units are axial leaded for

thru-hole mounting, encapsulated in an epoxy molded

case. High resistivity ferrite core, allows for high inductance

with low DC resistance.

Physical Parameters

Inches Millimeters

Length 0.740 ± 0.010 18.80 ± 0.25

Diameter 0.240 ± 0.010 6.10 ± 0.25

Lead Size

AWG #20 TCW 0.032 ± 0.002 0.813 ± 0.051

Lead Length 1.44 ± 0.12 36.58 ± 3.05

Operating Temperature Range –55°C to +125°C

Current Rating 40°C Rise over 85°C Ambient

Maximum Power Dissipation at 85°C 0.50 W

Inductance Measured at 1 V with no DC current

Incremental Current The current at which the inductance

will be decreased by a maximum of 5% from its initial zero

DC value.

Weight Max. (Grams) 2.5

Marking DELEVAN; inductance with units and tolerance;

date code (YYWWL). Note: An R before the date code

indicates a RoHS component.

Example: 2474R-02K

Front:

Reverse:

DELEVAN 0902A

1.2uH±10%

Packaging Tape & reel: 12" reel, 1000 pieces max.; 14"

reel, 1500 pieces max. For additional packaging options,

see technical section.

Made in the U.S.A.

Po

w

er I

nd

uc

to

rs

270 Quaker Rd., East Aurora NY 14052 • Phone 716-652-3600 • Fax 716-652-4814 • E-mail: [email protected] • www.delevan.com

SERIES 2474 FERRITE CORE

-01L

-02L

-03L

-04L

-05L

-06L

-07L

-08L

-09L

-10L

-11L

-12L

-13L

-14L

-15L

-16L

-17L

-18L

-19L

-20L

-21L

-22L

-23L

-24L

-25L

-26L

-27L

-28L

-29L

-30L

-31L

-32L

-33L

-34L

-35L

-36L

-37L

-38L

-39L

-40L

-41L

-42L

-43L

-44L

-45L

-46L

-47L

-48L

-49L

-50L

-51L

-52L

6.4

5.8

5.2

4.8

4.3

3.9

3.5

3.2

2.9

2.7

2.5

2.2

2.0

1.8

1.6

1.5

1.4

1.2

1.1

1.0

0.93

0.85

0.77

0.71

0.64

0.58

0.52

0.48

0.43

0.39

0.35

0.32

0.29

0.27

0.25

0.22

0.20

0.18

0.16

0.15

0.14

0.12

0.11

0.10

0.09

0.09

0.08

0.07

0.06

0.06

0.05

0.05

6.27

5.95

5.67

5.43

5.22

5.03

4.70

4.56

4.01

3.84

3.69

3.55

3.27

3.09

2.97

2.84

2.66

2.25

2.17

2.05

1.84

1.65

1.56

1.53

1.30

1.12

1.04

0.99

0.84

0.80

0.74

0.68

0.59

0.56

0.49

0.42

0.39

0.37

0.34

0.30

0.28

0.25

0.23

0.20

0.19

0.18

0.15

0.13

0.12

0.12

0.10

0.09

1.0

1.2

1.5

1.8

2.2

2.7

3.3

3.9

4.7

5.6

6.8

8.2

10.0

12.0

15.0

18.0

22.0

27.0

33.0

39.0

47.0

56.0

68.0

82.0

100.0

120.0

150.0

180.0

220.0

270.0

330.0

390.0

470.0

560.0

680.0

820.0

1000.0

1200.0

1500.0

1800.0

2200.0

2700.0

3300.0

3900.0

4700.0

5600.0

6800.0

8200.0

10000.0

12000.0

15000.0

18000.0

0.009

0.010

0.011

0.012

0.013

0.014

0.016

0.017

0.022

0.024

0.026

0.028

0.033

0.037

0.040

0.044

0.050

0.070

0.075

0.084

0.104

0.130

0.145

0.152

0.208

0.283

0.330

0.362

0.505

0.557

0.650

0.770

1.03

1.14

1.50

1.98

2.30

2.55

3.00

4.00

4.40

5.80

6.56

8.63

10.1

11.2

15.0

20.8

23.4

26.0

36.0

40.0

Optional Tolerances: J = 5% H = 3% G = 2% F = 1%

*Complete part # must include series # PLUS the dash #

For surface finish information, refer to www.delevanfinishes.com

1/2009

API_newlayouts_single:APIcatalog_newlayouts 8/26/10 12:17 PM Page 94