Schreiber Chillers 1055 New User Manual

Page 7

CryoCompressor 1⁄2” FPT

1.5 GPM

1⁄2”

Heat

Exchangers

1” FPT

16 GPM

1”

*Based on a total piping length of 300’ per loop.

Only use copper or PVC (schedule 80) piping. All piping should be insulated to prevent condensation

and to minimize heat gain from the ambient air. A maximum of 30% by volume of Ethylene Glycol can

be added to the system. The glycol should be added directly to the reservoir through the fill port. To

get the proper percentage, the reservoir volume should be added to the piping volume to get the total

amount of fluid in the system. Since both chilled water loops pull water out of the same reservoir, both

loop volumes should be calculated.

INHIBITED ETHYLENE GLYCOL MUST BE USED. DO NOT USE AUTOMOTIVE TYPE GLYCOL

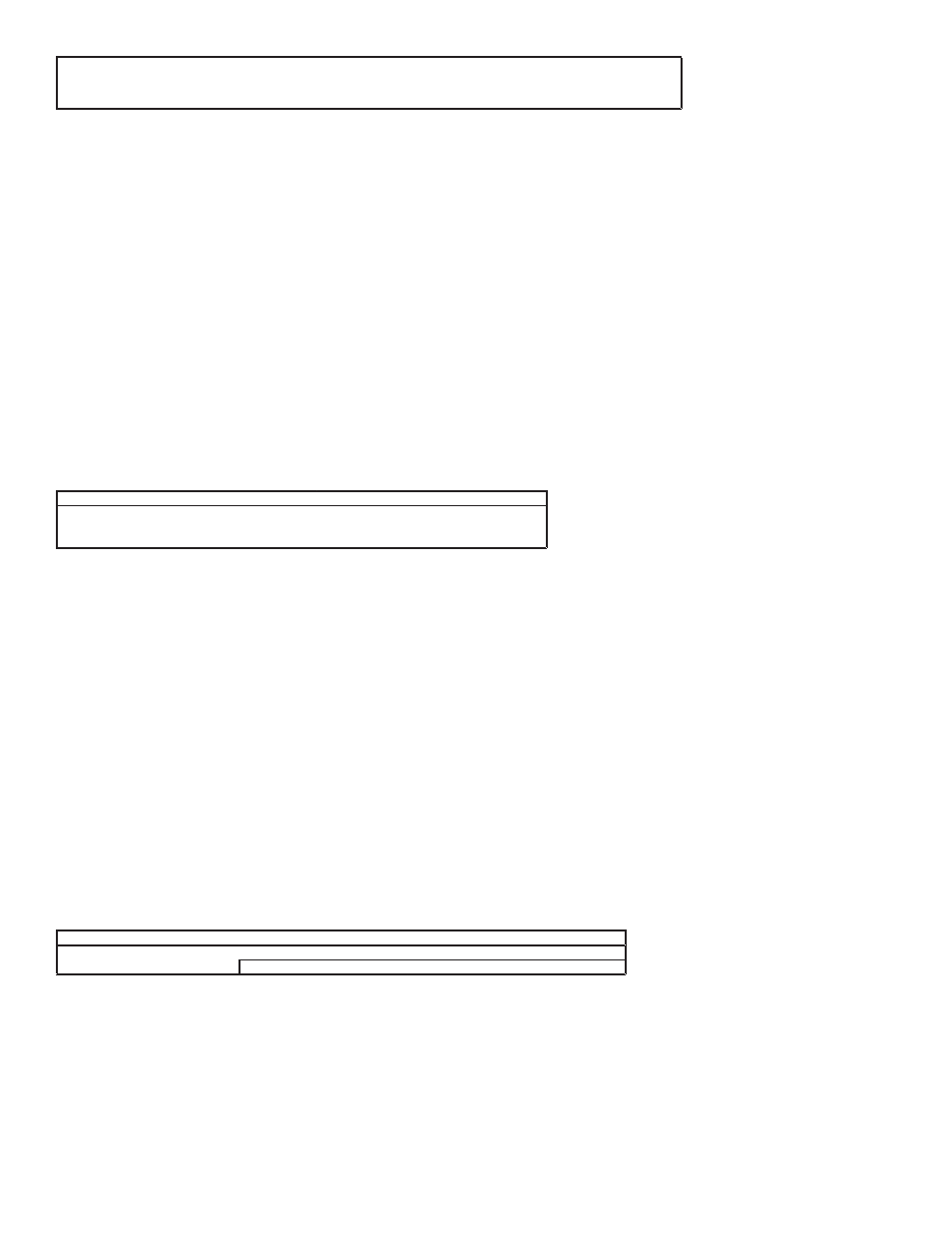

Pipe Size

(based on copper)

Volume (gal/100 ft.)

1⁄2”

1.2

3⁄4”

2.5

1”

4.3

A pressurized water supply and hose should be provided at the site for filling the chilled water

reservoir. Automatic fill systems are not used because of unintended glycol dilution.

Since the reservoir is vented to atmosphere, expansion tanks are not required in the piping system.

A float in the reservoir will send an alarm to check the water level in the reservoir, without shutting the

chiller down.

REMOTE CONDENSER PIPING

There are two circuits in this chiller, therefore four pipes are required to connect the chiller and

condenser.

Refrigeration Piping Guidelines

(Based on 150’ equivalent length)

Liquid Line

Hot Gas Line

1055RC

5/8”

3/4”

These values are based on 150’ of total piping length, plus equivalent length of fittings. Shorter runs

may allow for smaller pipes, but oversizing the Hot Gas line lowers the gas velocity, which prevents

proper oil movement through the system. This value MUST NOT BE EXCEEDED, for any length of

pipe.

Refer to the interconnecting diagram for more requirements on piping installation.