Schreiber Chillers 1055AC/RC HANDBOOK User Manual

Page 32

1055 SERVICE

NOTE: This section is for qualified service personnel only. Procedures outlined in this section of the

manual can cause personal injury or permanent damage to the chiller and the equipment it is cooling.

If you have any questions about the procedures outlined in this section please contact Schreiber

Engineering directly.

Refrigeration System

The 1055 is made up of two separate refrigeration system, the only shared components is the

condenser and it’s fans. A refrigeration system skid can be removed while the other system is

operating. Each system arrives from the factory charged with refrigerant.

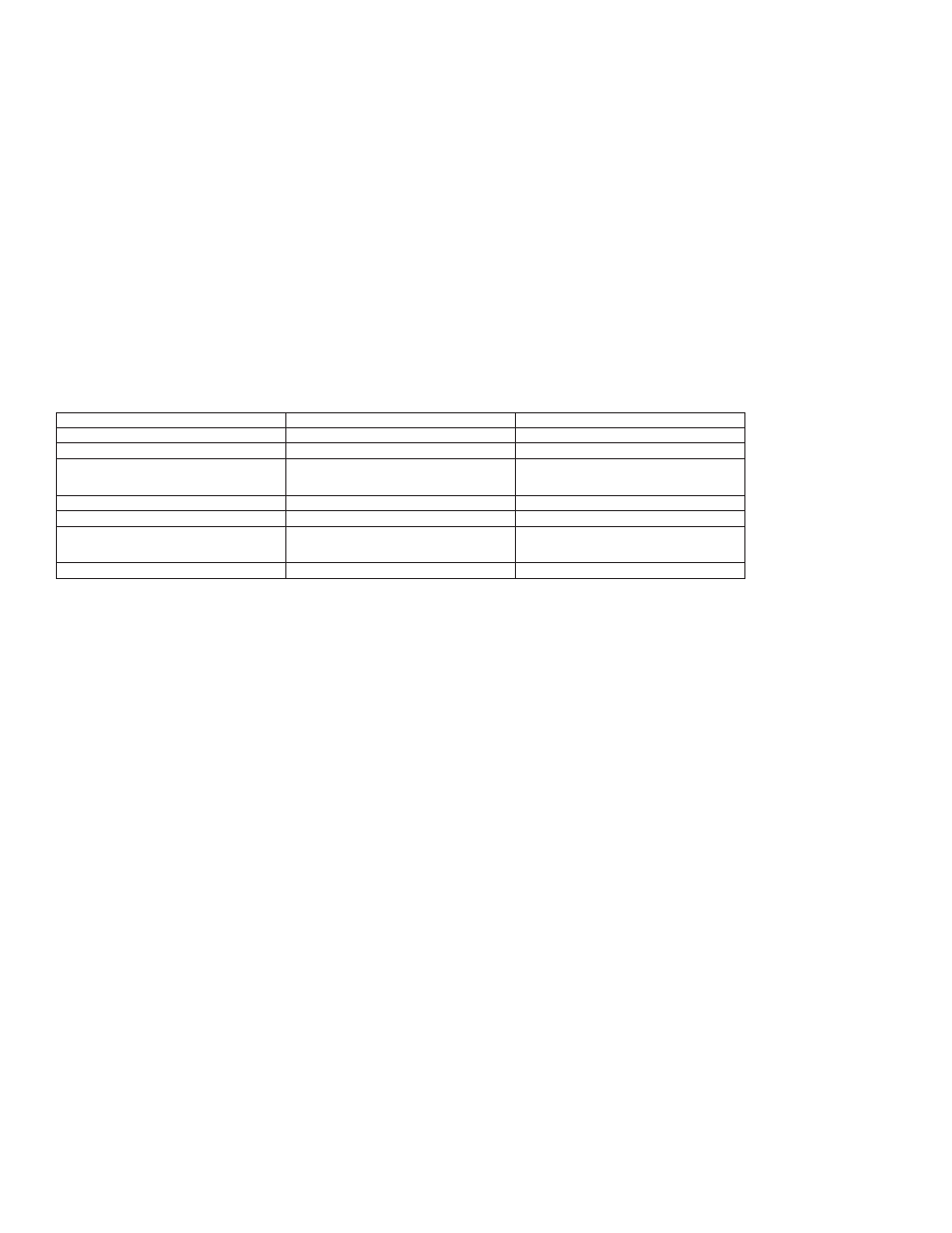

Normal Operating Parameters

Suction Pressure

50 psi

Head Pressure

250 psi

Superheat

10 F

Flow Rate (per

evaporator)

8 GPM

Charge (lbs per system)

12 lbs

Low Pressure Switch Set: 15 psi CO, 30 psi CI

High Pressure Switch

Set:

410 psi CO, 375 psi CI

Service Procedures

The following is a guideline for various procedures that may be performed on the refrigeration system

in the event of a mechanical or electrical failure.

System Charging

The system is shipped from the factory fully charged with refrigerant, but charging may be required

after the system has been pump down for component change out. It is assumed that all components

have been replaced, and that any leaks present have been repaired, and that the system has been

thoroughly purged and evacuated.

1. Charge with liquid 75% of the full charge into the receiver.\

2. Start PUMP 2 and compressor being charged as would normally be done. If system 2 is being

charged, shut down compressor 1 to force compressor 2 to cycle.

3. Charge with vapor to the low side until the factory charge is reached.

4. If the sight glass is still fuzzy after the factory charge has been reached, 1 or 2 more lbs can be

added to clear the sight glass. The chiller is factory operated at as close to actual conditions as

possible, so the charge may have to be adjusted slightly.

System Pump Down

1. Disable the LP alarm.

2. Close the receiver outlet valve, and cycle the compressor. TO force the compressor to cycle,

the discharge temperature setpoint can be set lower than the default.