3 servomotor/drive operation – PA Industries Edge Servo Roll Feed with SFI SRF-100/125/200/300/400/500/600 User Manual

Page 4

ULTRA EDGE SERVO ROLL FEED 2

/09/2002

4

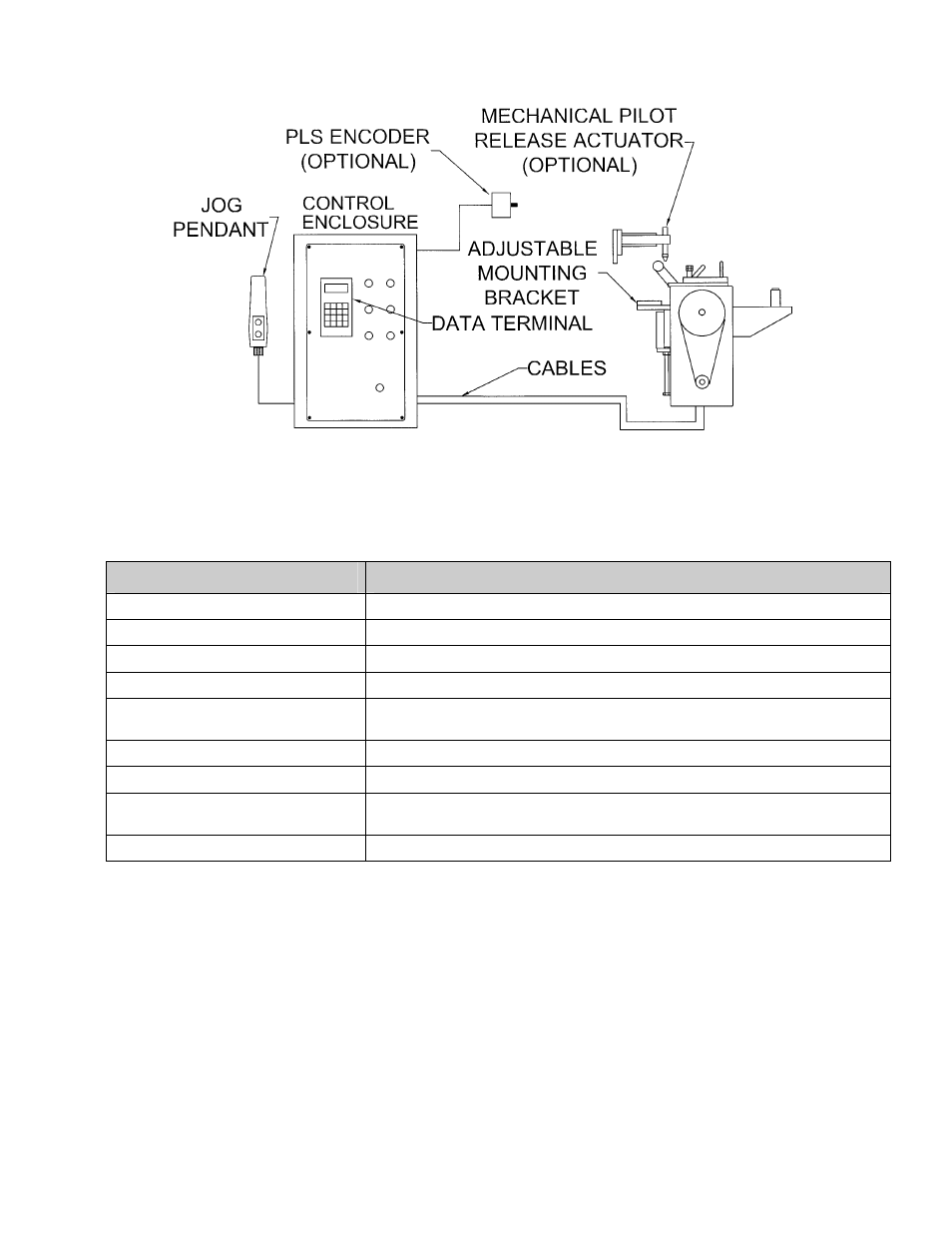

ALL ULTRA ADVENTAGE SERVO ROLL FEED CONTROLS ARE CONVENIENTLY

LOCATED ON THE FRONT SIDE OF THE ELECTRICAL ENCLOSURE

CONTROL/DEVICE

DESCRIPTION

Power On/Reset button

Turns controller on, resets the servo drive.

In Position indicator light, white

Turns on when move is complete and motor is holding position.

Cycle Start illuminated button, green

Turns controller into “Auto” mode from “Manual” mode, starts cycling.

Cycle Stop button, red:

Stops cycling and returns the controller into “Manual” mode.

“JTL / Manual-Auto” mode selector

switch:

Turns controller into “Manual” or “JTL” (Jog To Length) mode.

Emergency Stop mushroom button, red

Shuts controller off

Operator terminal

Displays controller’s data and enters data into controller.

“Programming Locked / Unlocked” key-

switch

Locks access to programming.

Forward / Reverse remote jog pendant

Pendant is attached to the enclosure through retractile cable.

2.3 SERVOMOTOR/DRIVE OPERATION

The introduction of servomotor technology to the press roll feed has pushed the limits of accuracy, adjustability,

and performance to levels previously unattainable.

The following example is based on the Ultra Edge Servo Roll Feed Standard, US (SRF-125, 200, 300, 400, 500,

600) models. The actual numbers for SRF-100 or metric models are different.

Each revolution of the servomotor produces 1048576 encoder pulses. Every 2.909 revolutions of the servo motor shaft

produce 1 revolution of the feed rollers. The circumference of the lower roll is approximately 11.138 inches.

When a new feed pitch is entered into the system, the built in computer calculates the correct number of electronic

“pulses” it must receive from the motor mounted encoder in order to rotate the feed rolls the correct distance.