Disassembly – DE-STA-CO 600RGD/RGS User Manual

Page 4

DISASSEMBLY

1. Remove all accessory equipment such as

clutches, reducers, sprockets, etc. If equipped

with a CAMCO R250 Reducer see disassembly

instruction pertaining to this reducer prior to

removal from unit.

2. Drain oil and flush unit with flushing solvent.

Retain any chips or broken pieces you may find.

These may aid in diagnosis.

3. Remove the access cover.

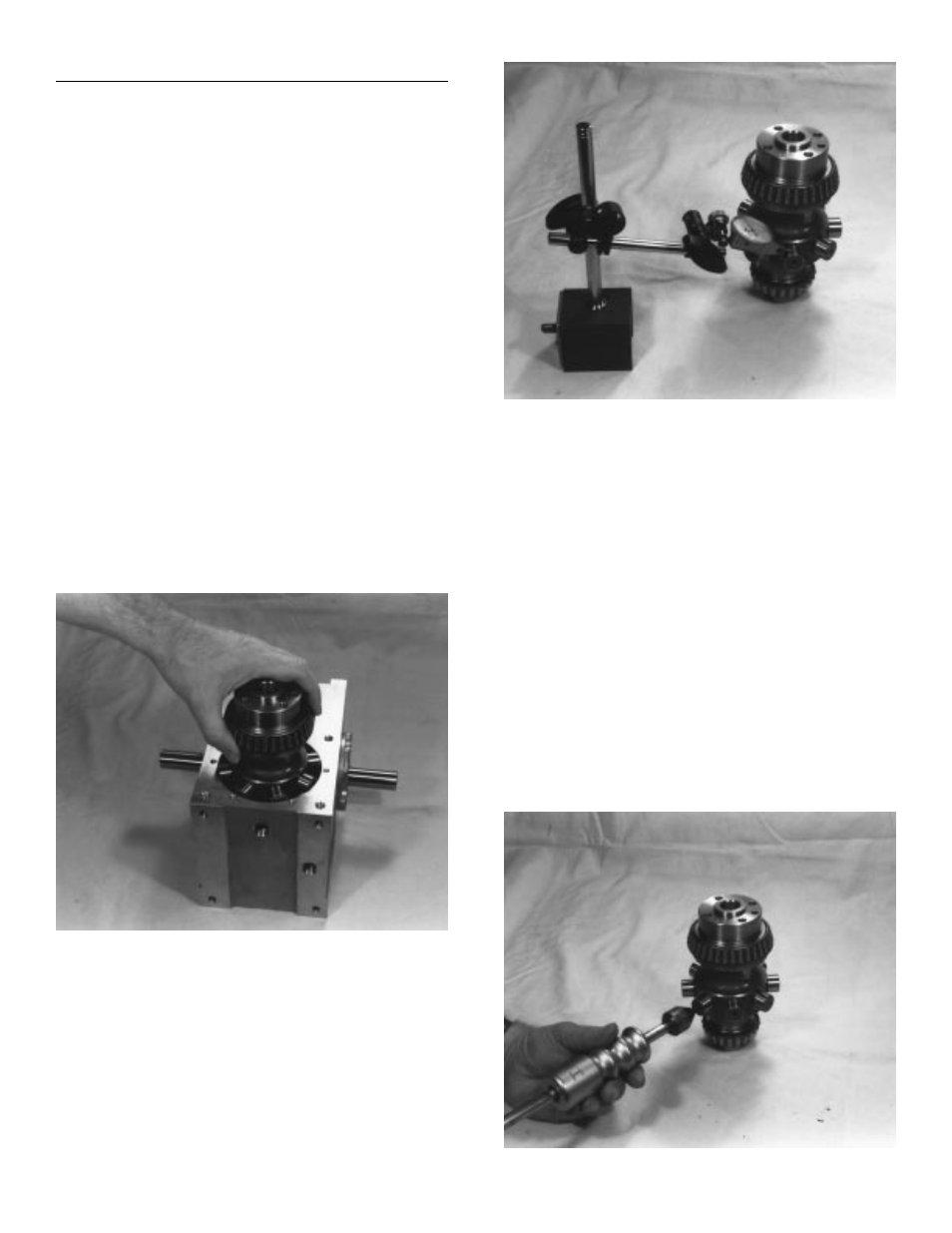

4. REMOVAL OF OUTPUT SHAFT.

A. Rotate the input shaft until the output is in

dwell (Where the rotation of the input shaft

does not effect the rotation of the output).

B. Remove all output bearing cartridge

capscrews.

C. Remove the output cartridge.

NOTE: Keep shims with the cartridge. You will be asked

to reinstall or replace with same shim thickness during

assembly.

D. Pull the shaft out through the cartridge

opening.

Fig.1 Removing output shaft.

5. INSPECTION OF CAM FOLLOWERS.

Inspect followers for damage or radial looseness. It

should not exceed .001 inch. Do not confuse radial

looseness with axial endplay. Endplay will be from

.03 to .06 as a normal condition. If it exceeds .06 it

may require replacement.

NOTE: Generally, followers are replaced as added

insurance against eventual failure.

Fig.2 Inspecting Follower.

6. FOLLOWER REMOVAL.

A. Remove the setscrews. Apply heat to the

setscrews holding the follower studs and

remove while still warm.

B. Threaded holes have been provided in the

ends of the follower for ease of removal.

Use a slide hammer or a simple self made

pull tool. The slide made pull tool consists

of a short piece of round tubing large

enough to clear the follower diameter and a

small flat bar with a clearance hole large

enough to insert a capscrew of equal thread

size as the follower pull hole. Slip the tube

over the follower, place the bar over the tube

and thread a capscrew into the follower

tightening the capscrew will remove the

follower.

Fig.3 Removing follower

3