DE-STA-CO 1800RDM User Manual

Page 8

E. Apply “Prussian Blue” to entire cam track.

F.

Rotate the camshaft slowly with a small

handcrank to ensure that:

1) Both rollers are in contact with the cam

rib in dwell. Look for uniform blueing

pattern.

2) The follower is free when it is in the

center of the crossover track.

3) You do not encounter unusual

resistance in motion. The bluing pattern

should be fairly uniform from side to side

during motion. If a patch of bluing is

worn off the outside of the cam rib on

one side of the cam and not the other,

shift the cam a .002 to .005 inches in the

direction of the worn side. Do not

overshift the cam or knocking will occur.

4) The cam bluing should never be worn

off the lead-in or exit edges of the cam

ribs. This would indicate that the cam is

not adjusted properly.

5) There should be no looseness in any

dwell. If there is looseness adjust the

output bearing retainer to slightly

preload the loosest dwell.

G. Tighten the locknuts and secure with

Loc-Tite #242 as specified in the “General

Service Manual”. If lockwashers are used on

your model, bend the tangs over the nut to

insure locking.

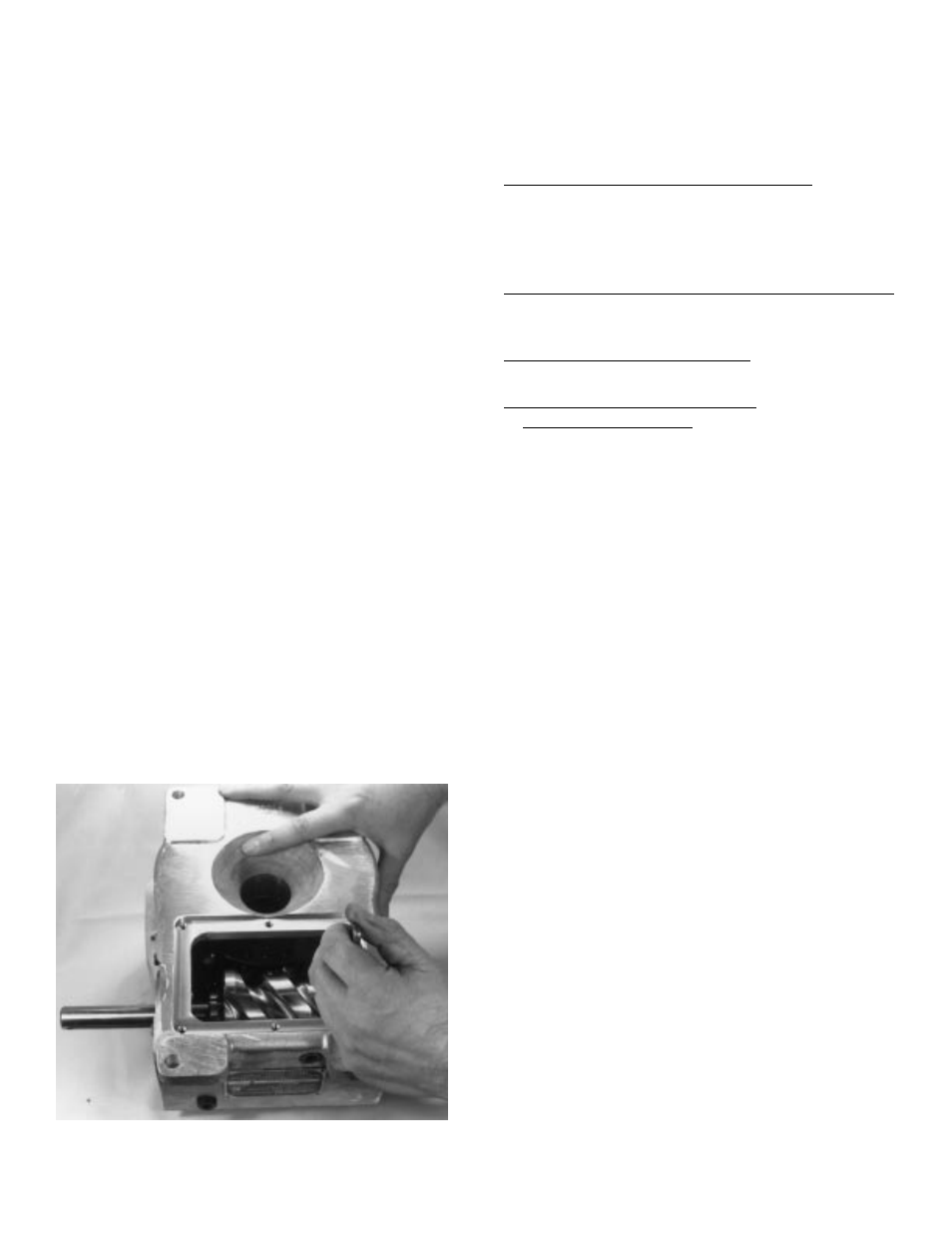

Figure 10 Tighten cam locknuts

H. Tighten the output retaining ring capscrews.

I.

Drill and ream the remaining hole in the

output retaining ring to accept the next

larger dowel pin. Install new dowel.

8. REINSTALL THE BOTTOM COVER. Apply

“General Electric Silicone Rubber RTV-6” to the

sealing surfaces of the housing and cover. Place

the gasket on the housing and place cover over

the gasket. Install and tighten capscrews.

9. GREASE PACK THE MAIN OUTPUT BEARING

with lubricant specified in the “General Service

Manual”.

10. INSTALL NEW OIL SEALS as described in

the “General Service Manual”.

11. FILL THE INDEX WITH THE

RECOMMENDED OIL to level indicator. See

“General Service Manual”. Too high an oil level

will cause no damage. Too low a level may result

in unit failure.

7