DE-STA-CO 1800RDM User Manual

Page 7

B. Install the bearing retainer capscrews and

washers. Use torque and Loc-Tite

recommendations from the “General

Service Manual”.

C. Install new followers with an arbor press.

CAUTION:

Be sure to press the followers in straight

as damage to the follower and wheel could occur if

improperly aligned during installation. Be sure that

the notches are aligned with the setscrew holes.

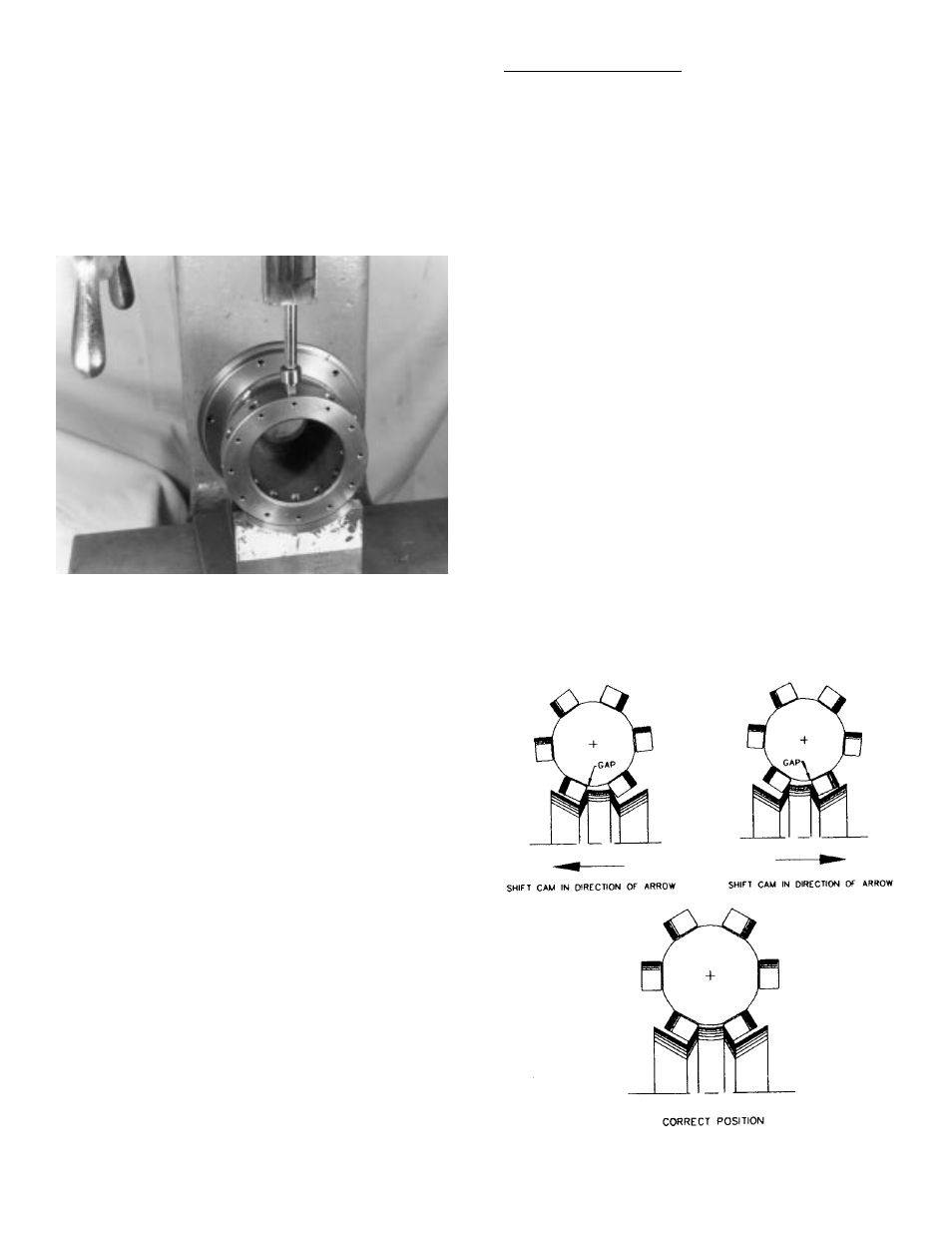

Fig. 8 Pressing in new followers

D. Install the setscrews with double-notch

followers, the cone point setscrews lock into

the “V” notch. The cup point setscrews lock

against the flat single-notch followers, use

an oval point setscrew. Be sure to use Loc-

tite thread locking liquid as recommended in

the “General Service Manual”.

E. Coat the inside of the bearing retainer ring

and the outside of the main output bearing

with anti-sieze lubricant. Place the bearing

retainer ring over the output from the

topside of the output/follower wheel and tap,

alternating from side to side until the

retainer is fully seated on the bearing.

F. Replace the shims removed in disassembly

step 4C.

G. Place cam in dwell position, keyway pointing

rearward.

H. Insert output/follower wheel into housing

with dowel holes in housing in line with

retainer.

I. Loosely install the bearing retainer

capscrews.

J. Install only one of the dowel pins through the

retainer ring into the housing.

4. SETTING THE CAM.

CAUTION: This mechanism is designed to operate

with adjacent followers in close contact along their

entire width, unless this condition is achieved by

proper installation, the mechanism will not transmit

its rated load,and serious damage to the cam and

output shaft will occur.

A. Place the unit on end or its side so both the

output side and the bottom opening are

accessible.

B. Place the cam in dwell, keyway facing

rearward.

C. While pivoting on the one dowel pin, rotate

the output towards the input shaft as much

as the clearance holes for the mounting

capscrews will allow.

D. Shift the cam axially until two adjacent

followers are in full contact with the cam rib.

This will also require adjustment of the

output retaining ring along with axial

adjustment of the cam.

1) If there is a gap at the root of the

follower the cam should be shifted

toward the follower.

2) If there is a gap at the tip of the follower

the cam should be shifted away from the

follower.

Fig.9 Shifting cam for proper alignment

6