AUMA Part-turn gearboxes GS 50.3 - 250.3, primary reduction gearings VZ 2.3 - 4.3_GZ 160.3 - 250.3 User Manual

Page 5

Primary reduction gearing

Primary reduction gearing

Planetary gear with various reduction ratios for reducing the input torques

Valve attachment

Valve attachment

Dimensions according to SP 101

Standard:

GS 50.3 – GS 125.3:

without spigot

GS 160.3 – GS 250.3: without spigot

Options:

GS 50.3 – GS 125.3:

with spigot

GS 160.3 – GS 250.3: with spigot

Splined coupling for connection

to the valve shaft

Standard:

without bore or pilot bore from GS 160.3

Worm gearbox can be repositioned 4 x 90° on coupling

Options:

Machined with bore and keyway, square bore or bore with two-flats

Service conditions

Enclosure protection according

to EN 60 529

6)

Standard:

IP 68-3, dust and water tight up to max. 3 m head of water

Options

7)

:

IP 68-6, dust and water tight up to max. 6 m head of water

IP 68-10, dust and water tight up to max. 10 m head of water

IP 68-20, dust and water tight up to max. 20 m head of water

Corrosion protection

Standard:

KN

Suitable for installation in industrial units, in water or power plants

with a low pollutant concentration

Options:

KS

Suitable for installation in occasionally or permanently aggressive

atmosphere with a moderate pollutant concentration

(e.g. in wastewater treatment plants, chemical industry)

KX

Suitable for installation in extremely aggressive atmosphere

with high humidity and high pollutant concentration

Paint

Standard:

GS 50.3 – GS 125.3:

Two-component iron-mica combination

GS 160.3 – GS 250.3: Two-component iron-mica combination

Color

Standard:

Grey (DB 702, similar to RAL 9007)

Option:

Other colors on request

Ambient temperature

Standard:

– 20 °F to + 175 °F/ – 25 °C to + 80 °C

Options:

– 40 °F to + 140 °F/ – 40 °C to + 60 °C (low temperature), version L

– 75 °F to + 140 °F/ – 60 °C to + 60 °C (extreme low temperature), version EL

+ 32 °F to + 250 °F/ – 0 °C to + 120 °C (high temperature), version H

Lifetime

Open-close duty: The lifetime is based on a load profile typical for part-turn valves

Modulating duty: min. 2.5 million operations

8)

6) Refer to section enclosure protection IP 68

7) Not available for GS 50.3

8) With worm wheel made of spheroidal cast iron

9) The lifetime for modulating duty depends on the load and the number of starts. A high starting frequency will rarely improve the modulating accuracy. To reach the

longest possible maintenance and fault-free operation time, the number of starts per hour chosen should be as low as permissible for the process

5

Operation instructions

Worm gearboxes GS 50.3 – GS 250.3

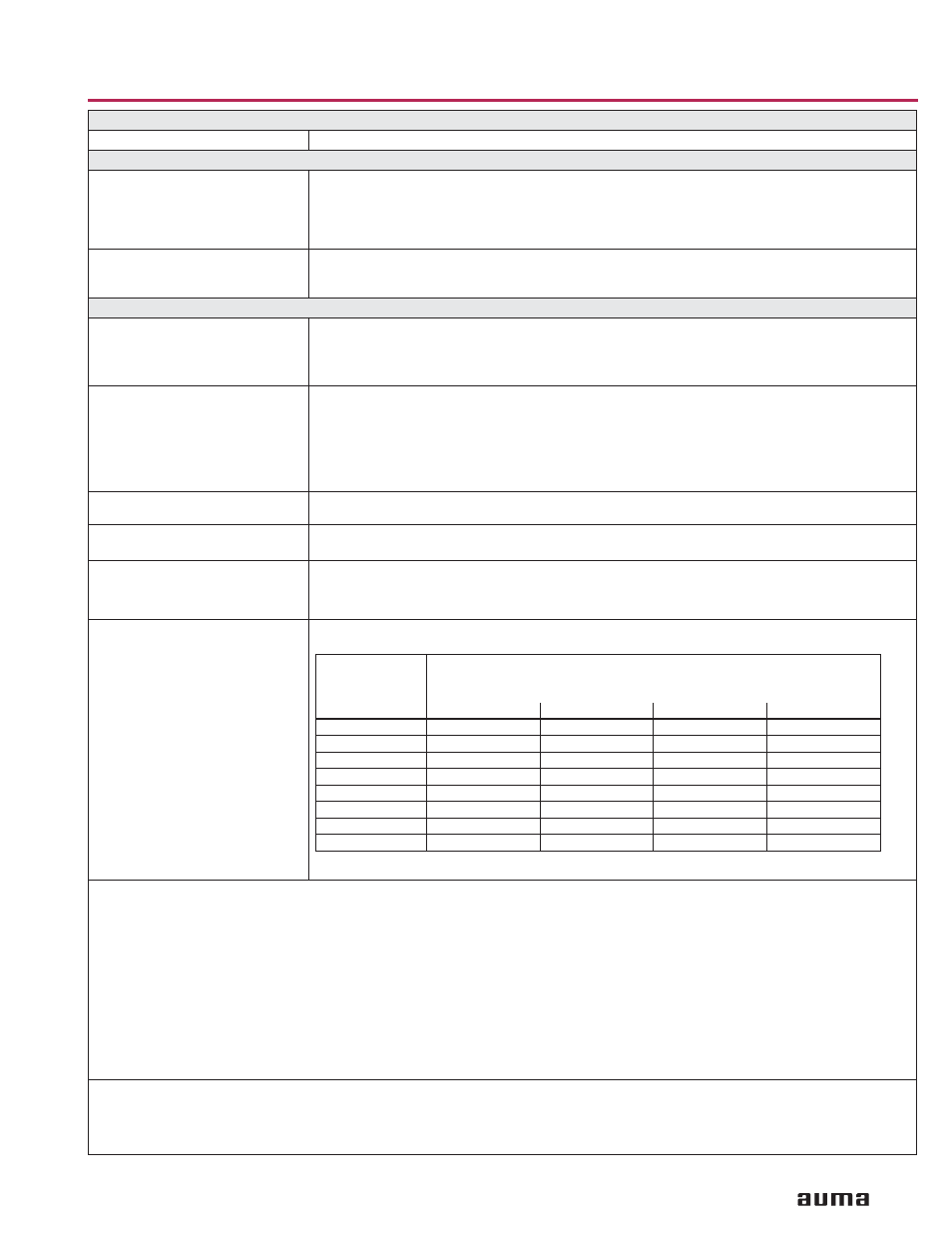

Type

Operating cycles (OPEN - CLOSE - OPEN)

for swivel movements of 90° (max. 100°)

and a maximum output torque of

100 %

140 %

175 %

8)

200 %

9)

GS 50.3

15,000

5,000

–

1,000

GS 63.3

15,000

5,000

–

1,000

GS 80.3

15,000

5,000

–

1,000

GS 100.3

15,000

5,000

–

1,000

GS 125.3

15,000

5,000

–

1,000

GS 160.3

15,000

5,000

1,000

–

GS 200.3

15,000

5,000

1,000

–

GS 250.3

10,000

3000

750

–