Mounting to valve, Mounting to valve 11 – AUMA Part-turn gearboxes GS 50.3 - 250.3, primary reduction gearings VZ 2.3 - 4.3_GZ 160.3 - 250.3 User Manual

Page 11

7.

Mounting to valve

AUMA worm gearboxes GS and primary reduction gearings VZ/GZ can be

operated in any mounting position.

.

For butterfly valves, the recommended mounting position is end position

CLOSED

(Prior to mounting, bring the gearbox to the mechanical end stop CLOSED by

turning the handwheel clockwise).

.

For ball valves, the recommended mounting position is end position OPEN

(Prior to mounting, bring the gearbox to the mechanical end stop OPEN by

turning the handwheel counterclockwise).

.

Alternatively, the limit stop housing can be turned up to the end position of the

respective valve.

.

Thoroughly degrease mounting faces of gearbox and valve.

.

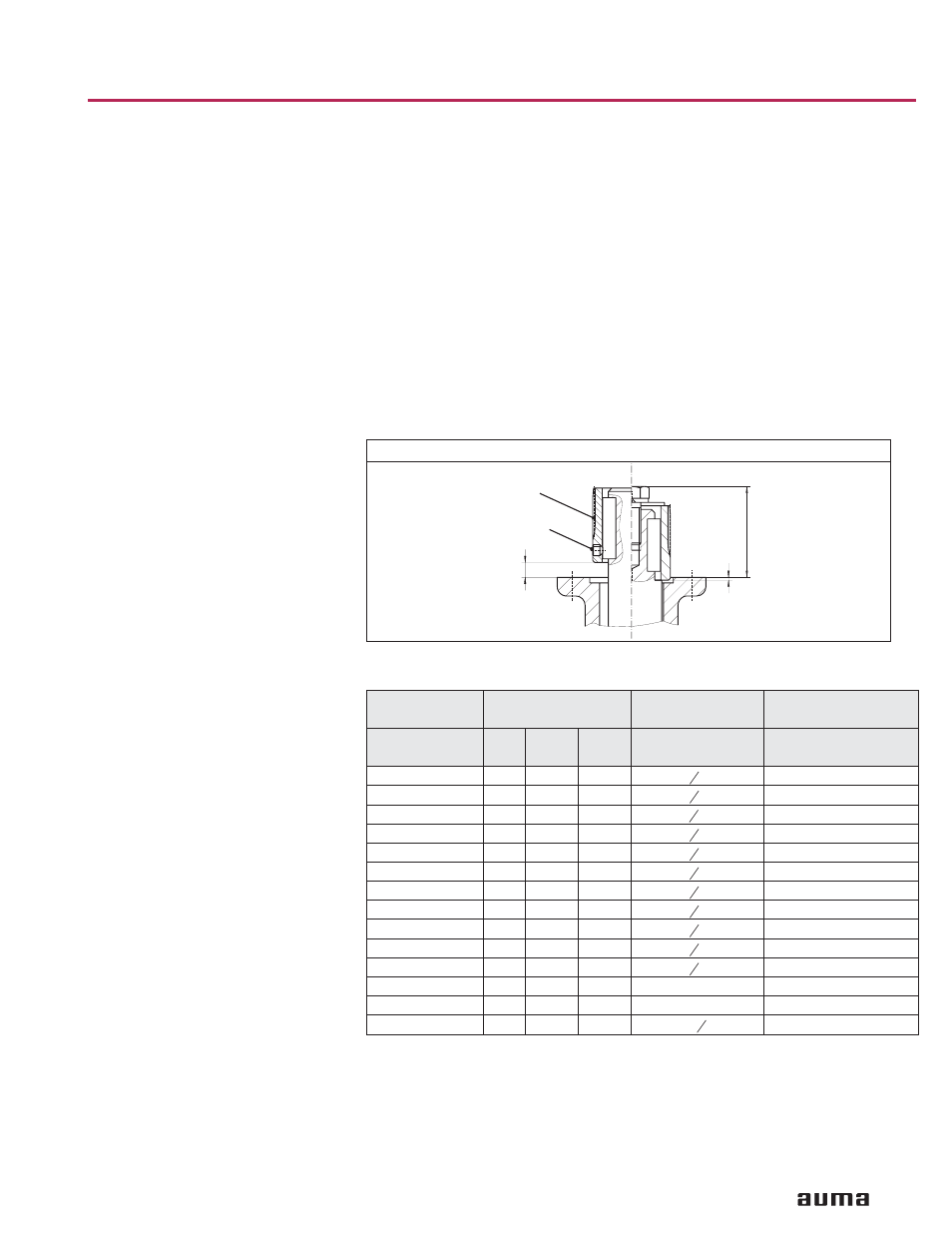

Place coupling sleeve onto valve shaft and secure (refer to figure C, detail A or B),

ensure that dimensions X, Y, and Z are observed (refer to table 2).

.

Apply non-acidic grease at splines of coupling.

.

Mount gearbox on valve. Ensure that the spigot (if provided) mates uniformly in the

recess and that the mounting faces are in complete contact.

.

Fasten gearbox with bolts (quality min. 8.8) and lock washers.

.

Fasten bolts crosswise with a torque according to table 2.

Note:

Experience showed that it is very difficult to fasten bolts or nuts of 1-8 UNC or

larger with the defined torques. The worm gearbox may be moved radially against

the valve flange by accident.

To improve adhesion between valve and gearbox, we recommend to apply

Loctite 243 (or similar products) on mounting faces.

11

Operation instructions

Worm gearboxes GS 50.3 – GS 250.3

A

X

B

Z

Y

Figure C

Coupling

Valve

Grub screw

Gearbox

Dimensions

Bolts

Strength class

Grade 5

Flange type

X

max

Y max Z max

Qty. x threads

(UNC)

Fastening torque T

A

[Ft lbs.]

GS 50.3-FA10

14

5

61

4 x

3

8

- 16

33

GS 63.3-FA10

7

18

73

4 x

3

8

- 16

33

GS 63.3-FA12

10

13

76

4 x

1

2

- 13

78

GS 80.3-FA14

23

5

88

4 x

5

8

- 11

155

GS 100.3-FA14

22

13

123

4 x

5

8

- 11

155

GS 100.3-FA16

22

8

123

4 x

3

4

- 10

257

GS 125.3-FA16

17

35

126

4 x

3

4

- 10

257

GS 125.3-FA25

17

27

126

8 x

5

8

- 11

155

GS 160.3-FA25

15

11

130

8 x

5

8

- 11

155

GS 160.3-FA30

30

0

140

8 x

3

4

- 10

255

GS 200.3-FA30

19

19

160

8 x

3

4

- 10

255

GS 200.3-FA35

44

0

190

8 x 1 - 8

590

GS 250.3-FA35

8

8

220

8 x 1 - 8

590

GS 250.3-FA40

13

0

230

8 x 1

1

4

- 7

1,200

Table 2: Standard dry fastening torques for bolts