Technical data, Technical data 4 – AUMA Part-turn gearboxes GS 50.3 - 250.3, primary reduction gearings VZ 2.3 - 4.3_GZ 160.3 - 250.3 User Manual

Page 4

4

2.

Technical data

Features and functions

Version

Standard: clockwise rotation RR, counterclockwise rotation LL, option: RL or LR

Housing material

Standard: cast iron (GJL-250), Option: spheroidal cast iron (GJS-400-15)

Self-locking

The gearboxes are self-locking when at stand-still under normal service conditions; strong

vibrations may cancel the self-locking effect. While in motion, safe breaking is not guaranteed. If

this is required, a separate brake must be used.

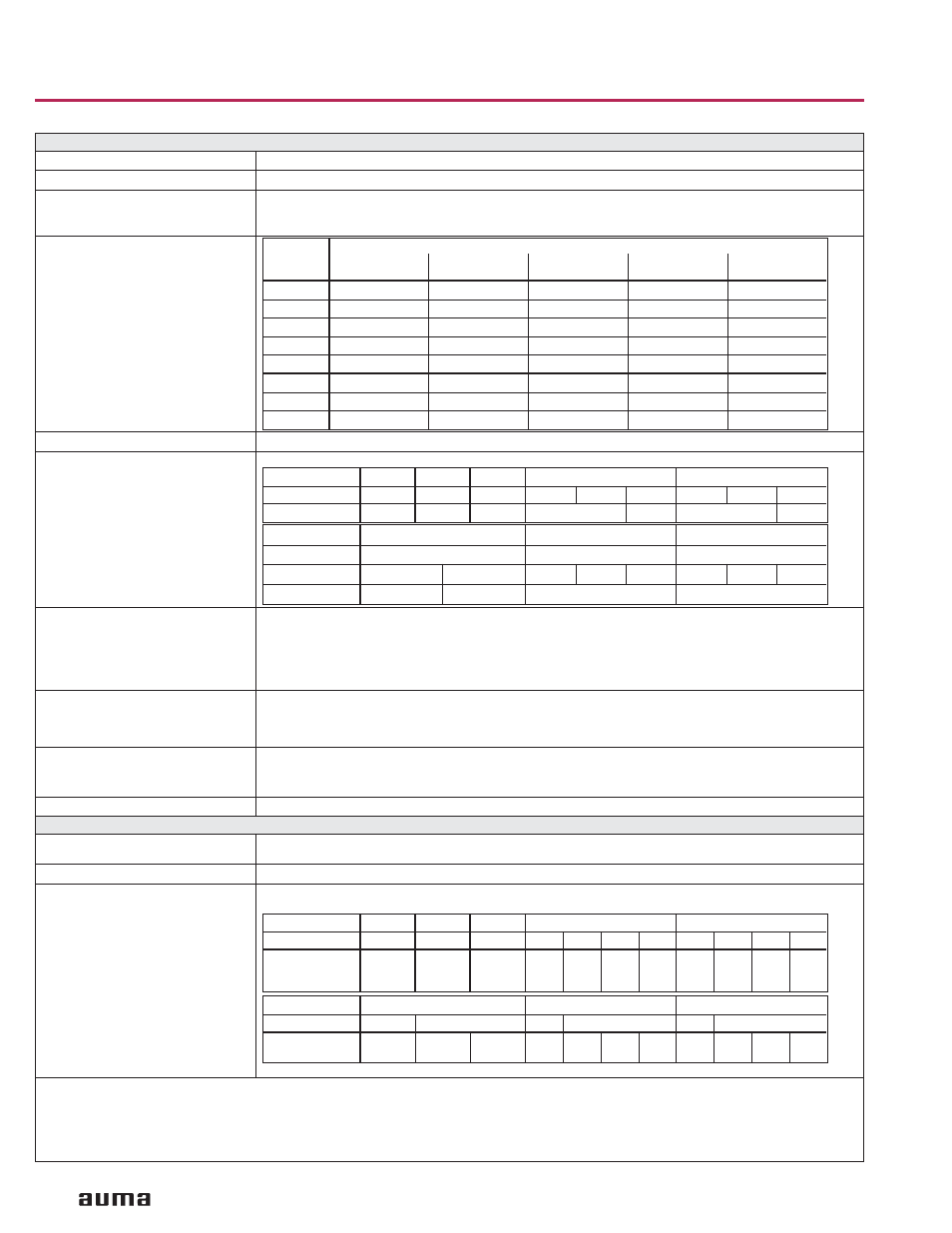

Output torques

End stops

Positive for both end positions by traveling nut, sensitive adjustment

Strength of end stop

Guaranteed strength of end stop (in ft lbs.) for input side operation

Swing angle

GS 50.3 – GS 125.3

Standard:

Fixed swing angle up to max. 100°; set in the factory to 92° unless ordered otherwise.

Options:

Adjustable in steps of:

10°– 35°, 35° – 60°, 60° – 80°, 80° – 100°, 100° – 125°, 125° – 150°,

150° – 170°, 170° – 190°

For version with worm wheel made of bronze: swing angle > 190°,

Multi-turn version without end stops, version GSD

3)

Swing angle

GS 160.3 – GS 250.3

Standard:

Adjustable 80° – 100°; set in the factory to 92° unless ordered otherwise.

Options:

Adjustable in steps of: 20° – 40°, 40° – 60°, 60° – 80°,

For version with worm wheel made of bronze: swing angle

>

100°,

‘

Multi-turn version without end stops, version GSD

3)

Mechanical position indicator

Standard:

Pointer cover for continuous position indication

Options:

Sealed pointer cover for horizontal outdoor installation

4)

Protection cover for buried service instead of pointer cover

Input shaft

Cylindrical with parallel key according to DIN 6885.1

Operation

Motor operation

With electric multi-turn actuator, directly or through primary reduction gearing VZ/GZ

Flanges for mounting of actuator, refer also to separate technical data sheets.

Type of duty

According to actuator

Manual operation

5)

Via handwheel, directly or through primary reduction gearing VZ/GZ

Available handwheel diameters, selection according to the max. output torque:

25.4 mm correspond to 1 inch

1) With worm wheel made of spheroidal cast iron

2) Requires worm wheel made of bronze

3) Special sizing is required

4) For gas applications with sealed pointer cover, an air vent in the pointer cover or venting grooves in the valve mounting flange must be provided

5) Handwheel sizes shown reflect general industrial selection criteria. For information on gearbox/handwheel selection in accordance with AWWA Standard C504, please

refer to separate selection list/chart.

Worm gearboxes GS 50.3 – GS 250.3

Operation instructions

Type

Output torques

100 %

140 %

175 %

1)

200 %

1)

Modulating torque

2)

max. ft lbs.

max. ft lbs.

max. ft lbs.

max. ft lbs.

max. ft lbs.

GS 50.3

184

258

–

369

92

GS 63.3

369

516

–

738

184

GS 80.3

738

1,033

–

1,475

369

GS 100.3

1,475

2,065

–

2,950

738

GS 125.3

2,950

4,130

–

5,900

1,475

GS 160.3

5,900

8,298

10,326

–

2,950

GS 200.3

11,801

16,595

20,652

–

5,900

GS 250.3

23,602

32,822

41,303

–

16,000

Type

GS 50.3

GS 63.3

GS 80.3

GS 100.3

GS 125.3

Reduction gearing

–

–

–

–

VZ 2.3 VZ 3.3 VZ 4.3

–

VZ 2.3 VZ 3.3 VZ 4.3

Handwheel Ø

mm

160

200

250

250

315

315

400

400

500

315

400

315

400

250

315

500

630

800

400

500

400

500

315

400

Type

GS 160.3

GS 200.3

GS 250.3

Reduction gearing

–

GZ 160.3

–

GZ 200.3

–

GZ 250.3

Handwheel Ø

mm

630

800

400

315

–

500

630

400

315

–

800

500

630

400

Type

GS 50.3

GS 63.3

GS 80.3

GS 100.3

GS 125.3

Reduction gearing

–

–

–

VZ 2.3

VZ 3.3

VZ 4.3

VZ 2.3

VZ 3.3

VZ 4.3

ft lbs.

185

330

330

370

185

370

185

Type

GS 160.3

GS 200.3

GS 250.3

Reduction gearing

GZ 160.3

GZ 200.3

GZ 250.3

Reduction ratio

4:1

8:1

4:1

8:1

16:1

4:1

8:1

16:1

ft lbs.

370

330

370

370