Maintenance, 1 general notes, Lubricant 19 – AUMA Part-turn gearboxes GS 50.3 - 250.3, primary reduction gearings VZ 2.3 - 4.3_GZ 160.3 - 250.3 User Manual

Page 19: General notes

12.

Maintenance

12.1 General notes

After commissioning, check worm gearbox for damage to paint finish.

Do a thorough touch-up to prevent corrosion.

Original paint in small quantities can be supplied by AUMA.

AUMA worm gearboxes require only very little maintenance.

To ensure that the worm gearbox is always ready to operate,

we recommend for

gearboxes operated less than 10 times per year,

the following measures:

.

Approximately six months after commissioning and every year after check bolts

between multi-turn actuator, worm gearbox, and valve for tightness. If required,

tighten applying the torques given in table 2 (page 11).

.

Perform a test run every six months.

.

Perform a visual inspection for grease leakage on each gearbox every

2 years.

.

Carry out a detailed functional test for each gearbox every 5 years. Record the

results for future reference.

.

For gearboxes permanently exposed to ambient temperatures above

104 °F, maintenance must be performed at shorter intervals.

Seals:

Seals made of elastomeric materials are subject to ageing. The theoretical usable

lifetime of the seals made of NBR is 13.5 years from the date of manufacture.

These figures are based on an average ambient temperature of 104 °F. Seal kits

may be obtained from AUMA.

Grease:

A grease and seal change is recommended after the following operation time:

.

if operated seldom after 10 – 12 years

.

if operated frequently, after 6 – 8 years

.

in modulating duty after 4 – 6 years

.

Only original AUMA grease must be used.

.

For the grease type, refer to the name plate.

.

Lubricants should not be mixed.

The removed lubricant and the cleaning agent used must be

disposed of according to the relevant regulations.

Operation instructions

Worm gearboxes GS 50.3 – GS 250.3

19

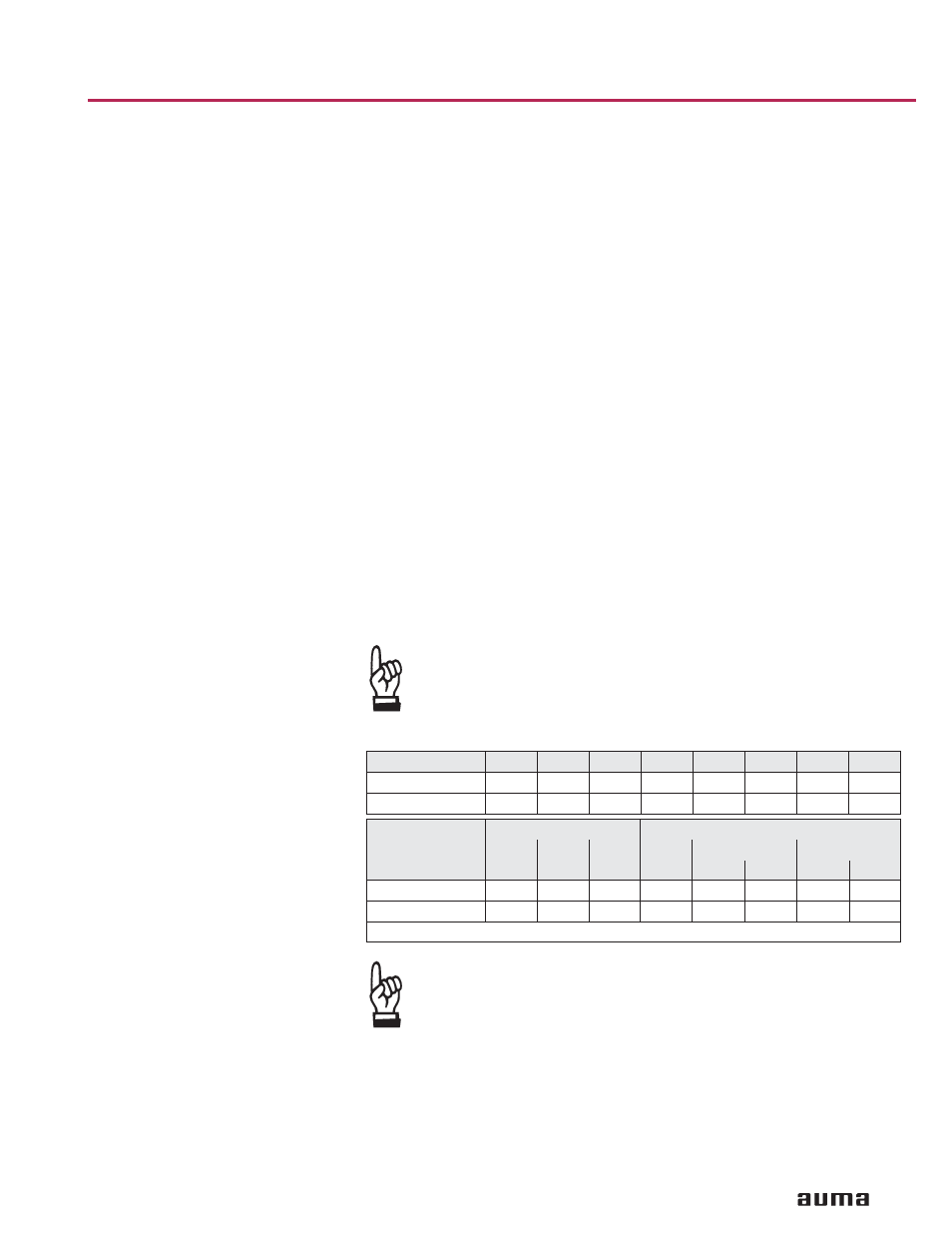

GS

50.3

63.3

80.3

100.3

125.3

160.3

200.3

250.3

Qty

dm³

0.1

0.3

0.4

1.0

1.3

3.3

6.6

12.2

Weight

1)

g

90

270

360

900

1,170

3,000

6,000

11,000

Primary

reduction

gearing

VZ

GZ

2.3

3.3

4.3

160.3

200.3

250.3

4:1/8:1

16:1

4:1/8:1

16:1

Quantity

dm³

0.35

0.35

0.35

1.0

1.5

2.0

2.2

2.8

Weight

1)

g

320

320

320

900

1,400

1,800

2,000

2,250

1) for

ρ = approx. 900 g/dm

3

; conversion factor: 1 oz corresponds to 28.35 g

Table 4: Grease quantities for worm gearboxes and primary reduction gearings