Sequence mode, Analysis function, Highest accuracy – Atec Tettex-MIDAS-288x Series User Manual

Page 3

C

Haefely has a policy of continuous product improvement. Therefore we reserve the right to change design and specification without notice.

LL_MIDAS288x_0711_LW - 3/6

a brand of

Haefely is a subsidiary

of Hubbell Incorporated.

SEQUENCE MODE

Executable test sequences (step macros) can be defined

with

Set-ups:

Set all configuration values, type of DUT,

insulation type, temperature correction function, limits,

work order, serial numbers, test personal, location, etc.

Test levels:

Set the desired different test levels (voltage

and frequency).

Connections:

Set the different connections (DUT wiring)

e.g. GSTg A+B.

Measuring values:

Define the different values to be

recorded. E.g. Voltage, Frequency, PF, Current, Insulation

Temperature, PF@20°C, etc.

Test instructions:

In every step that requires a rewiring

of the test object an instruction box with text and pictures

can be defined to provide the test personal with a step by

step guide of how to perform the connection, wiring and

the test.

Pass/fail levels:

Limits can be set absolute or relative

(based on reference measurements) that will be compared

with the measured values and shown in the analysis

diagram.

All this can be done on the MIDAS itself or with the office

software package on a separate PC or laptop.

A predefined test sequence then can be performed by

lower skilled or educated personal. It reduces the set up

time in the field and also reduces failures due to lack of

knowledge, wrong connections or misinterpretation of

measuring values.

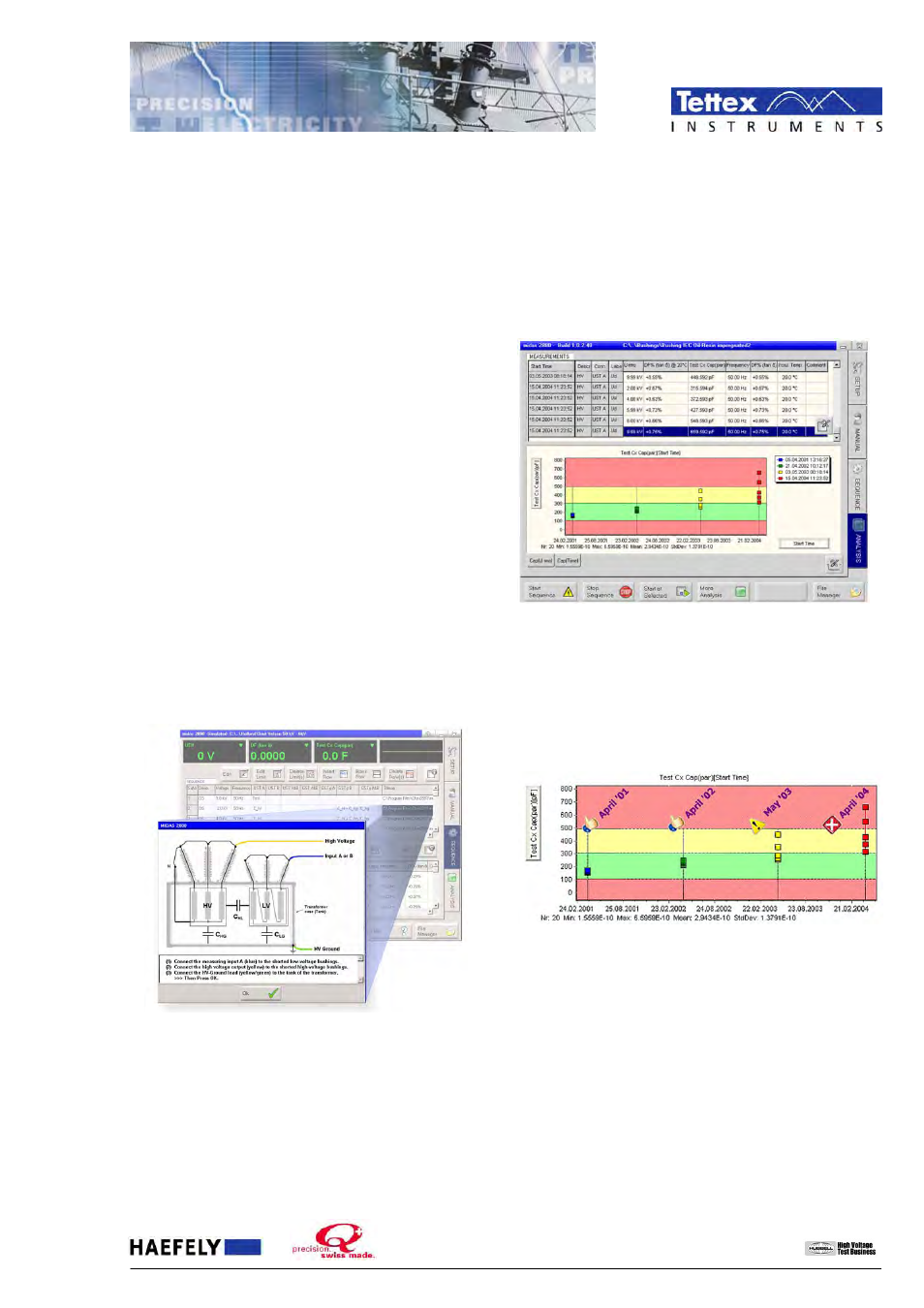

The pop-up test instruction window with a connection diagram

picture and below the corresponding instruction text

The Sequence mode is the perfect tool to repeat

maintenance measurements. If you have already done one

complete measurement you can reload it, perform an

identical test, collect the additional measurements and

display the new trending. As easy as that!

ANALYSIS FUNCTION

As an immediate on-site assessment you can compare the

latest measurements with stored data sets and see how the

insulation values have changed (trending), using the

analysis diagram. Also comparison of measurements

captured at different voltages and different frequencies can

be observed.

The ANALYSIS window with the list of stored measurements (top)

and the corresponding diagram window (bottom)

Both axis of the analysis diagram are free definable and the

collected sets of different measuring data can be sorted as

selected. So almost any dependency can be shown and

displayed.

If the Pass/Fail criteria are set they are shown in the

diagram as a green “Pass” band, a yellow “Attention”

band and a red “Failed” section. So you can immediately

identify a possible problem in your insulation.

The ANALYSIS diagram shows the trending and the limits.

HIGHEST ACCURACY

Due to the technology used for this advanced test

equipment we reached the highest accuracy in the market.

The

built-in reference is a standard gas capacitor

,

developed in-house, proven over 60 years, used as a

calibration standard for high voltage laboratories and

metrology national institutes. This guarantees the highest

long-term stability unbeaten by any other reference

standard. Because of the design of our standard capacitor,

the stability and the accuracy is independent of the

temperature, air pressure and humidity of the environment

so there is no need for additional verification. It’s all built-in

already and all calibrations are done automatically as part

of the self-test at boot-up. That’s our interpretation of

“accuracy by design”.