Atec Sumitomo-Type-66 User Manual

Splicers, Fusion, Tuff cat

Fusion and T

ermination Pr

oducts

For ordering assistance, please contact Customer Service at 800-358-7378 or visit our website at: www.sumitomoelectric.com

0712

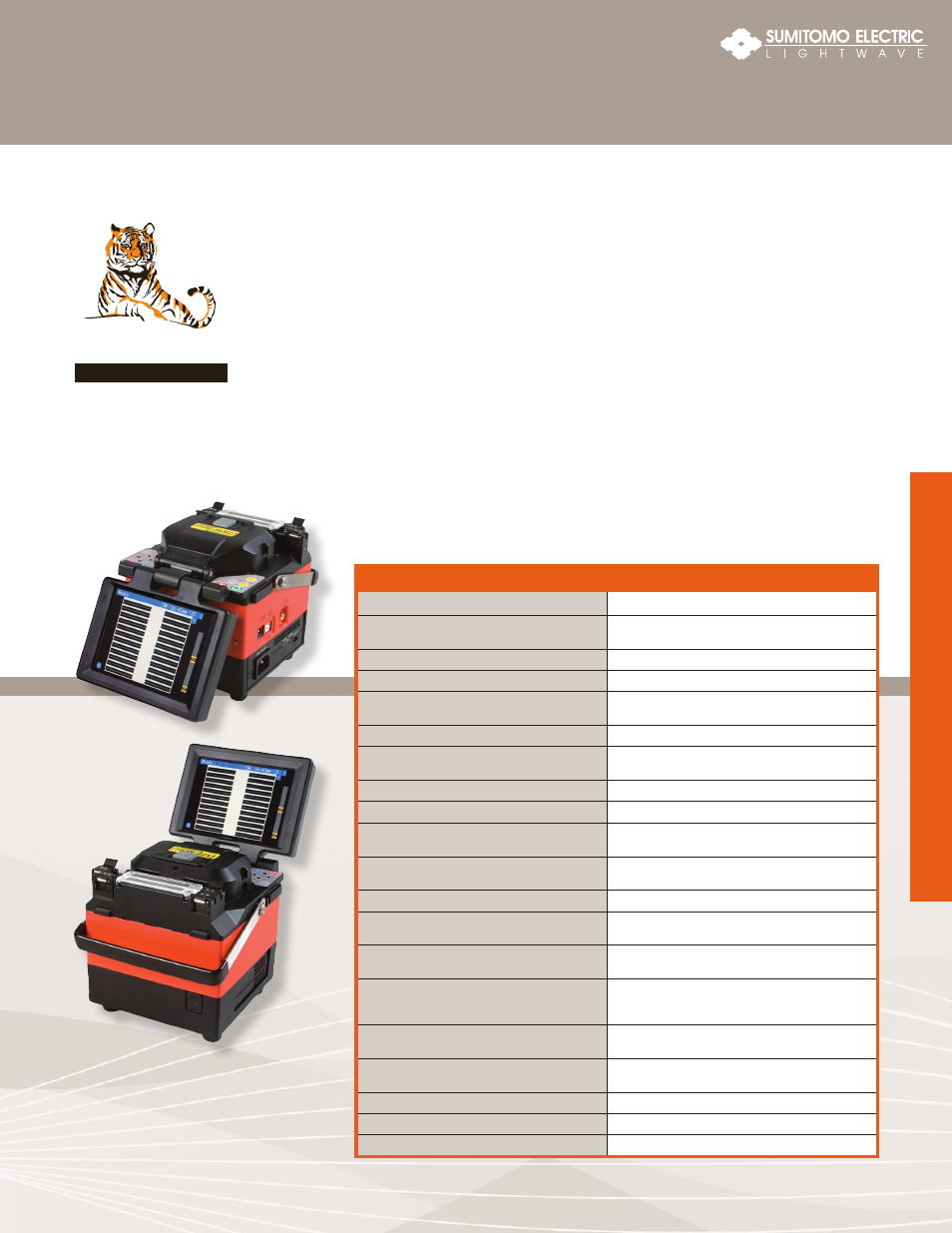

TuffCat

®

Type-66

Dual Heater

Mass Fusion Splicer

Description:

The Type-66 TuffCat mass fusion splicer

features the industry’s first Dual-Automatic-

Splice Protection Sleeve Heater System —

Sumitomo’s exclusive patent-pending system.

The dual heater system’s simultaneous

operation helps to eliminate squandered time

waiting for a single heater system to complete

its cycle. Instead, the streamlined splicing

process reduces the bottle neck of “heater

wait time” by 88%, improving mass splicing

efficiency and productivity in the field by 70%.

The TuffCat features an effortless fiber holder

system to increase splice repeatability while

making the unit easy to use regardless of the

operator’s experience level. Utilizing precision

v-groove alignment, the TuffCat can be used

for all types of ribbon and single splicing with

an optimum arrangement for ease of use in

trunk, aerial or taut-sheath applications.

The TuffCat mass fusion splicer embodies

Sumitomo’s mission of customer focused

engineering by reducing the customer’s

overall cost of ownership. The unit features

electrodes common with both the Type-39

FastCat and Type-25e TomCat splicers to

reduce the customer’s inventory cost, as well

as simplifying the ordering process.

The Type-66 is also compatible with the new

breakthrough technologies of the Lynx2-MPO

and Lynx2 CustomFit

®

Splice-On Connectors

(SC, LC, FC, and ST) for customized, on-site

terminations. These Splice-On Connector

technologies meet the network’s demand for

greater optical fiber density and for faster

and easier terminations, upgrades, repairs

and restorations, and significant cost savings

required for today’s data center, enterprise

network, outside plant, OEM, central office,

and virtually any FTTx application.

Alignment Method

Fixed V-groove

RoHS Compliant

(engineered to be more environmentally friendly)

Fiber Requirement

Silica Glass

Number of Fibers 1-12

Fiber Placement

Fiber Holder System

(Unified Holders for Type 25e/Type 66/Type-65)

Cladding Diameter 125µm

Coating Diameter

Ribbon 250µm

Single: 250 and 900µm

Typical Splice Time

20 seconds

Typical Splice Loss, Identical Fibers

SMF: 0.04dB, MMF:0.03dB, NZ-DSF: 0.07

Built-In Dual Splice Protection

Dual Independent Splice Protection

Sleeve Heater

Sleeve Heaters

Heater Cycle Time

Heater 1 40 seconds

Heater 2 40 seconds

Arc Test Compensation Automatic

DC (Battery Operation)

Standard: 70 Splices & Heater Cycles

Extended Life: 140 Splices & Heater Cycles

Arc Test

Automatically Compensates for

Environmental Conditions

Interface

USB for PC Interface

RCA Jack for External Monitor

12 Volt DC Output for Accessories

Display Type

5.6 Color TFT Low Glare High Resolution

Color monitor

Display Positions

Multiple Positional for Front to Back/ Back to

Front Work Flow

Selectable Language Options

18 Language Options including Spanish

Lynx—CustomFit™ Splice-On Connector Compatible

Splice Data Storage

2000 Splice Points

Specifications

Splicers

Fusion

S P L I C E R

Tuff

Cat