Atec MB-Dynamics-MB1000VI User Manual

Page 2

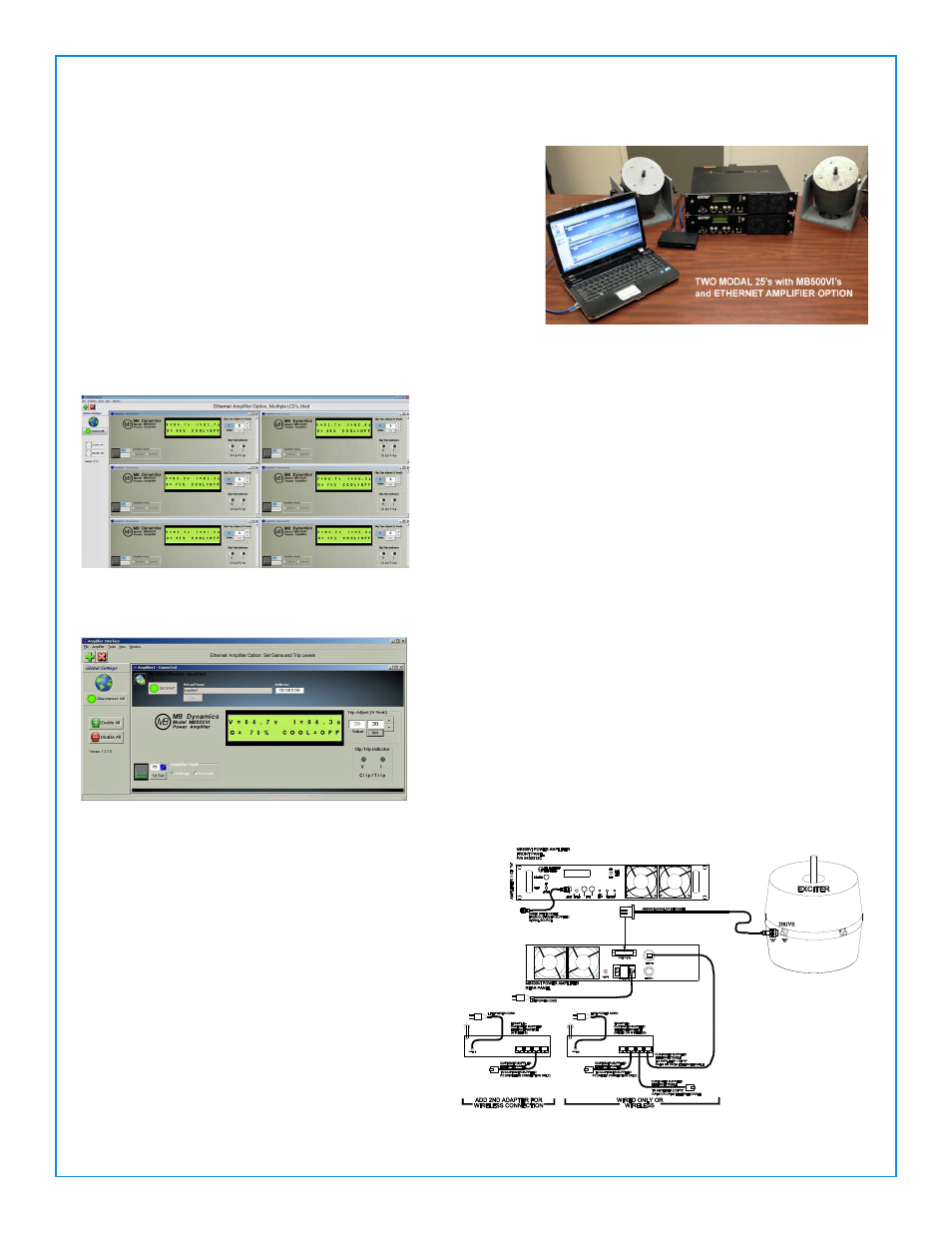

Options for the MB500VI and MB1000VI Amplifiers

Option 1: Ethernet Amplifier Operation

Each amplifier with this option has an embedded microcontroller with

an internal Ethernet adapter that communicates with a Windows app

allowing an operator to remotely setup, operate, gain-adjust, and moni-

tor one or any number of microcontroller-based amplifiers up to 16, es-

pecially beneficial in a multi-exciter modal test. The amplifier’s gain and

other settings can be adjusted and reset either locally at the amplifier’s

front panel or remotely through the Windows app via a standard Ether-

net network (wireless or wired) -- duplicate and parallel functionality for

all features in this option.

JOBS-TO-BE-DONE with this Option

1) Set-up and operate the amplifier from the modal data acquisition and

analysis PC (networked, Windows-based, 32/64-bit) through an Ethernet

network (wireless or wired) when amplifier is close to the exciter but at

a distance from user (remote, safely up to 100m distant); 2) Remotely

change amplifier output gain; adjust current & voltage clip and shutdown

(trip) values; switch between voltage & current mode operation; ENABLE

/DISABLE amplifier status; 3) Remotely mimic or duplicate same amplifier

functions as are available at amplifier front panel; 4) Remotely monitor

amplifier running status / faults as well as output voltage, current, gain,

error messages; 5) Perform all the above using 1-16 amplifier/exciter

combinations distributed around a test structure.

User Value

1) Eliminate need to physically be at each amplifier to set it up, oper-

ate and monitor its status; 2) Optimize and change output gains for each

amplifier based on structure’s response by adjusting gains from modal

analysis PC without physically changing gain settings at each amplifier

-- individual gains for each amp/exciter combination -- to prevent over

driving any particular exciter; 3) Set current and voltage max values to

protect from over-driving a particular exciter or driving point; 4) Manage

experimental modal survey by observ-ing operating status and diagnos-

tics of each amplifier on one PC monitor, not at many individual amplifier

front panels; 5) Minimize voltage drops along exciter drive cables and

the associated loss of available force by locat-ing an

amplifier close to its exciter not distant from the ex-

citer but convenient to user; 6) Data logging (at user

intervals) of gain setting, output voltage, output cur-

rent, trip settings, etc. to support restarts at current

set points or returns to previous set points.

Deliverables

Ethernet Amplifier interface hardware with internal

network adapter having unique static IP address;

PIC micro-controller and software; Ethernet cables

and network switch; and Windows PC-based Remote

Amplifier Operation software. User may provide ad-

ditional standard Ethernet hardware & cabling as de-

sired to customize Ethernet amplifier network layout

for wireless connectivity.

TECHNOLOGY · TEST PROCESSES · ENGINEERING SERVICES

DATA SHEET