Accurate measurement – Atec Konica-Minolta-CS200 User Manual

Page 3

R&D

Procurement/production

Data compatibility

Data compatibility

R&D

Regular instrument

(CS-200)

Regular instrument

(CS-200)

Regular instrument

(CS-200)

Regular instrument

(CS-200)

Regular instrument

(CS-200)

Design

Quality management

Reference

instrument

Production

Quality

management

R&D

Regular instrument

(CS-200)

Production

Quality

management

R&D

Regular instrument

(CS-200)

Production

Quality

management

R

l

i

t

t

In-house

color

management

ment

m

Color

management

with

customer

companies

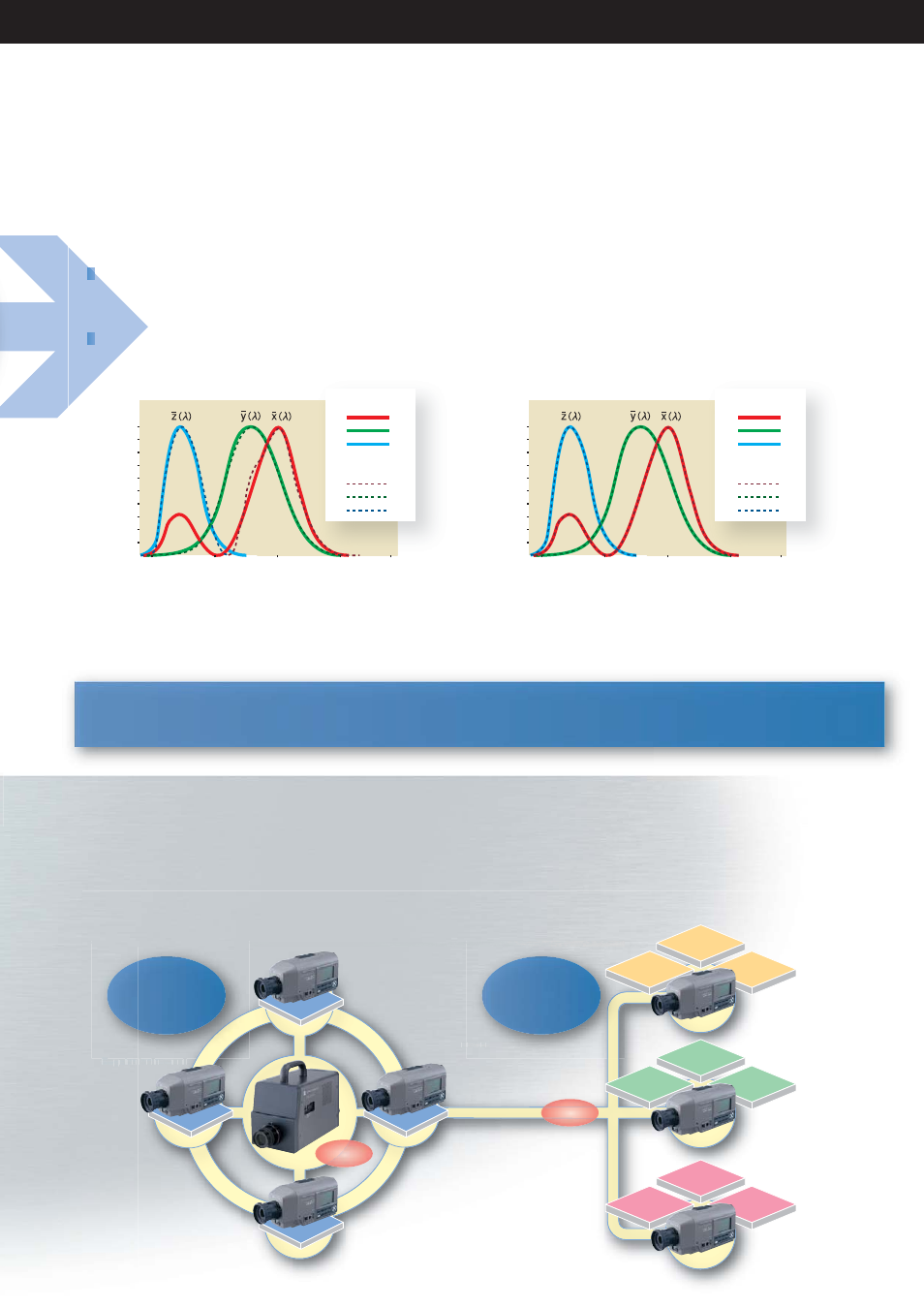

CIE 1931

color-matching functions

380 400

500

600

700

780

Spectral response of

conventional tristimulus

colorimeters

Relative

sensitivity

Relative

sensitivity

Wavelength (nm)

1.0

0.5

CIE 1931

color-matching functions

380 400

500

600

700

780

Spectral response

of the CS-200

Wavelength (nm)

1.0

0.5

CIE 1931 color-matching functions and spectral response

of the CS-200

CIE 1931 color-matching functions and spectral response

of a conventional tristimulus colorimeter

Company A

Company B

Company C

Konica Minolta's newly-developed spectral fitting method provides tristimulus values (XYZ = red, green, blue)

with significantly higher accuracy than that of conventional tristimulus colorimeters. This is achieved by using

the output from 40 sensors to calculate the spectral response corresponding to human eye sensitivity (CIE 1931

color-matching functions).

The CS-200 uses 40 sensors for sensitivity covering the entire visible region and multiplies each sensor output

by appropriate coefficients. This adjusts the spectral response of the instrument to close to the CIE 1931 color-

matching functions.

In additon to the 2 Standard Observer, the 10 Standard Observer (for object-color measurements) can also be

selected, which is impossible with conventional tristimulus colorimeters.

g

g

p

p

p

p

of the CS-200

g

g

p

p

p

p

of a conventional tristimulus colorimeter

Accurate measurement

"Spectral fitting method" for accurate luminance &

chromaticity measurement.

KONICA MINOLTA's Chroma Meter for accurate light-source measurement

allows building of a color management network both internally and externally.

In R&D and design departments

There is no need for calibration work to determine a

value of each light source by using a reference

spectroradiometer. For displays like LCDs or organic

ELs in particular, user calibration for the reference

panel using a spectroradiometer can be eliminated

1

.

1 If higher accuracy is required, user calibration can be used.

In quality management and incoming

inspection departments

Since individual errors are minimized compared

to

conventional tristimulus colorimeters, the inspection of

various devices such as panels does not require

individual error correction.