The ultrasonic advantage – Atec Panametrics-25DL User Manual

Page 4

Metal:

Plastic:

Glass:

Rubber:

Fiberglass:

Composites:

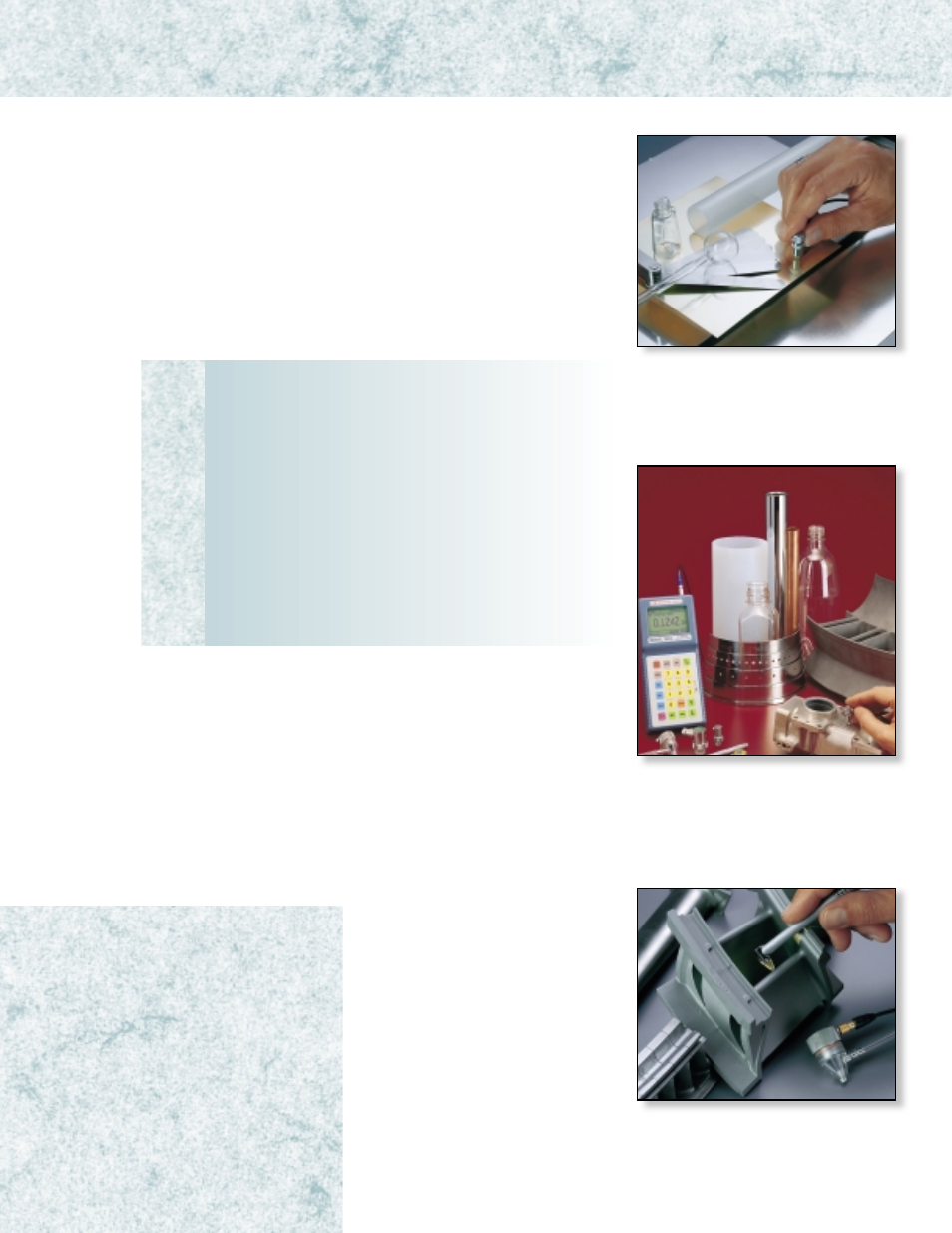

Multi-measurement modes using contact, delay line, and immersion transducers

enable the 25DL to be the ideal solution for almost any thickness measurement

application problem:

The 25DL is an All-In-One Solution

for a Wide Range of Thickness

Gaging Applications

The Ultrasonic

Advantage

Ultrasonic thickness

measurements are accurate,

reliable, repeatable, and most

importantly, nondestructive.

With the 25DL you achieve

instant digital measurements by

transmitting sound into the test

part from only one side, making

it unnecessary to cut or section

parts. Save material, time, and

labor in applications where the

opposite side is difficult or

impossible to access.

Coils, Containers, Plates, Machined Parts,

Cast Parts, Turbine Blades, Cylinder Bores, Tubing

Bottles, Containers, Drums, Hot Plastics, Pipes,

Tubes, Preforms, Sheets

Bottles, Bulbs, Tubes

Sheets, Tubes, Belts, Tires

Boat Hulls, Storage Tanks, Pipes

Panels, Radomes, Structures

Thin Material/High Resolution

The 25DL measures thin steel down to 0.006"

(0.15mm) or plastic as thin as 0.003" (0.08mm).

General Purpose

The 25DL measures materials such as steel up

to 20" (500mm) and even rubber, fiberglass,

and castings.

Special Applications

The 25DL measures in areas that are sharply

curved or hard to reach using the Sonopen

®

or

immersion transducers.

Panametrics also has available the

Models 25DL-HP and 25DL-RR

The Model 25DL-HP High Penetration’s capability is ideal for thickness

measurements on fiberglass, rubber, composites, and castings.

The Model 25DL-RR calculates and displays the percent of thickness

reduction after any material thinning process.