Optional energy measurement, Optional pipe wall thickness gauge transducer, Infrared port – Atec GE-Sensing-Tech-PT878 User Manual

Page 3: Optional infrared thermal printer and accessories, Built to be economical and stay economical

Optional Energy Measurement

The TransPort PT878 flowmeter combines proven

ultrasonic flow measurement with precise RTD

temperature measurement to determine the energy

flow rate in liquid heating and cooling systems. With

this option, the TransPort flowmeter comes equipped

with a built-in power supply for loop-powered

RTD temperature sensors, as well as all necessary

circuitry and software to make energy flow rate

measurements. The energy kit option includes two

matched Pt1000 surface mount RTDs with 30 feet of

cable to plug into the PT878,

Optional Pipe Wall Thickness Gauge

Transducer

Pipe wall thickness is a critical parameter used

by the TransPort flowmeter for clamp-on flow

measurements. The thickness-gauge option allows

accurate wall thickness measurement from outside

the pipe.

Infrared Port

The TransPort PT878 contains an infrared port

for communication with your PC. If your laptop or

desktop PC does not have infrared capability, an

adapter is available that can be plugged into your

PC’s serial port.

Optional Infrared Thermal Printer

and Accessories

When you need a permanent record of your work,

live measurements, logged data and site parameters

can be sent to a variety of printers by beaming data

directly from the TransPort PT878’s infrared port. A

compact, lightweight, hand-held, infrared thermal

printer is available. This printer is powered by a

lithium ion battery.

Built to Be Economical and Stay

Economical

To be of real value, a portable flowmeter must be as

economical to own and operate as it is capable in the

field. The TransPort PT878 flowmeter is built to stay

in service for many years. Completely solid state, the

device rarely wears out or needs servicing, resulting in

little downtime and low maintenance costs.

The TransPort PT878 Flowmeter Uses

the Transit-Time Flow Measurement

Technique

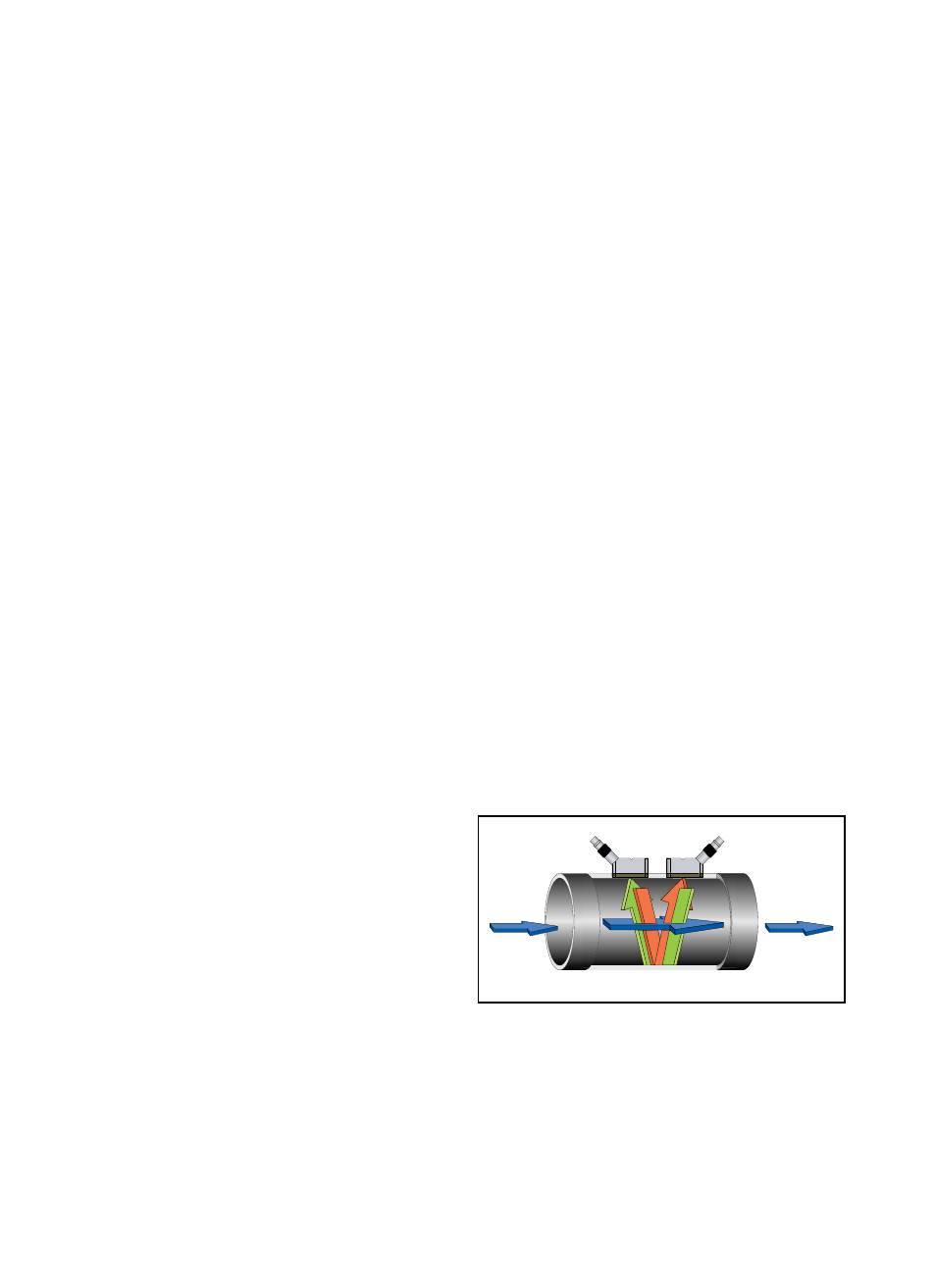

In this method, two transducers serve as both

ultrasonic-signal generators and receivers.

When mounted on a pipe, they are in acoustic

communication with each other, meaning that the

second transducer can receive ultrasonic signals

transmitted by the first transducer and vice versa.

In operation, each transducer functions as a

transmitter, generating a certain number of acoustic

pulses, and then as a receiver for an identical number

of pulses.

The time interval between transmission and reception

of the ultrasonic signals is measured in both

directions. When the liquid in the pipe is not flowing,

the transit-time downstream equals the transit-time

upstream. When the liquid is flowing, the transit-time

downstream is less than the transit-time upstream.

The difference between the downstream and

upstream transit times is proportional to the velocity

of the flowing liquid, and its sign indicates the

direction of flow.

Ultrasonic Signal Path

Flowmeter Transducers

Fluid

Flow

Transit-time flow measurement technique