Atec SCS-SMDII User Manual

Page 2

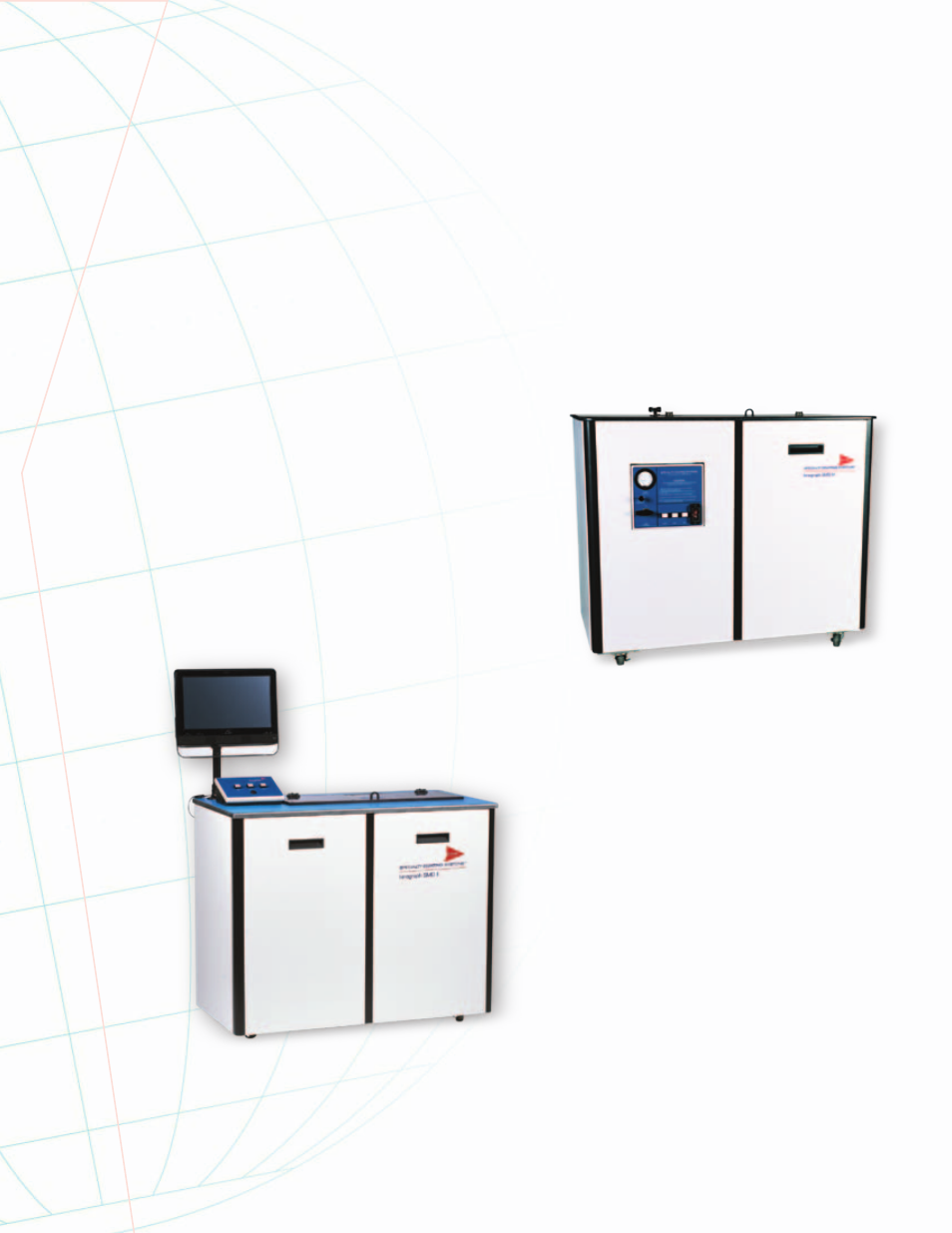

Ionograph® SMD II

with onboard all-in-one computer

SCS Ionograph Test Systems

SCS offers a full range of capacity and control to

meet the needs of any lab or manufacturer. Designed

for fast and accurate ionic contamination cleanliness

testing, SCS Ionographs:

• Determine the cleanliness of electronic

components, assemblies with SMT devices, and

bare and assembled printed circuit boards.

• Provide an accurate, repeatable and rapid method

for determining cleanliness on location.

• Provide immediate process control results,

negating the need for outside laboratory testing.

• Verify proper cleanliness of surfaces prior

to the application of conformal coatings or

potting compounds.

• Comply with current industrial specifications

such as ANSI/J-STD-001 and IPC-TM-650,

and obsolete military specifications, e.g., MIL-

STD-2000A.

SCS Ionograph SMD II and IV

SCS Ionograph SMD II and IV are floor units

commonly used for larger circuit boards in high-

volume production environments. Submerged

agitation jets and heated extract solution provide

outstanding sensitivity, operation efficiency and

the ability to test ultra-fine pitch components

with ease and accuracy.

The SCS Ionograph SMD II and IV offer users

the ability to test components with a heated or

non-heated test solution. IPC-TM-650 describes

the benefit of a heated solution to “accelerate

and improve the efficiency of extraction of ionic

material from poorly accessible regions, such as

under surface-mounted components.” In addition

to increasing cleaning efficiency, a heated system

also ensures temperature consistency of the test

solution, whereas solution temperature in an

unheated system can vary due to circulation

pump friction created during the testing process.

The SMD II model is now available with a

convenient onboard all-in-one computer,

providing efficient control and monitoring of

the test system using SCS PowerView™ software.

The SMD IV is the first ionic testing system

in the market to offer Bluetooth® technology

for wireless communication. In addition to

NFPA compliance, the SMD IV is also the first

cleanliness testing unit that is ETL-listed to

UL STD 61010-1, ATEX and CE compliant, and

nitrogen-inerted for added safety.

Specialty Coating Systems’ name is synonymous in the industry with automated

ROSE (Resistivity of Solvent Extract) testing systems. SCS Ionograph® ionic

contamination test systems utilize the dynamic extraction method to measure

resistivity change when a substrate is submerged in the ultra-pure test solution.

The degree of change in resistivity indicates the level of contamination, which

is often the result of residues from fabrication and board assembly processes.

Ionograph® SMD IV