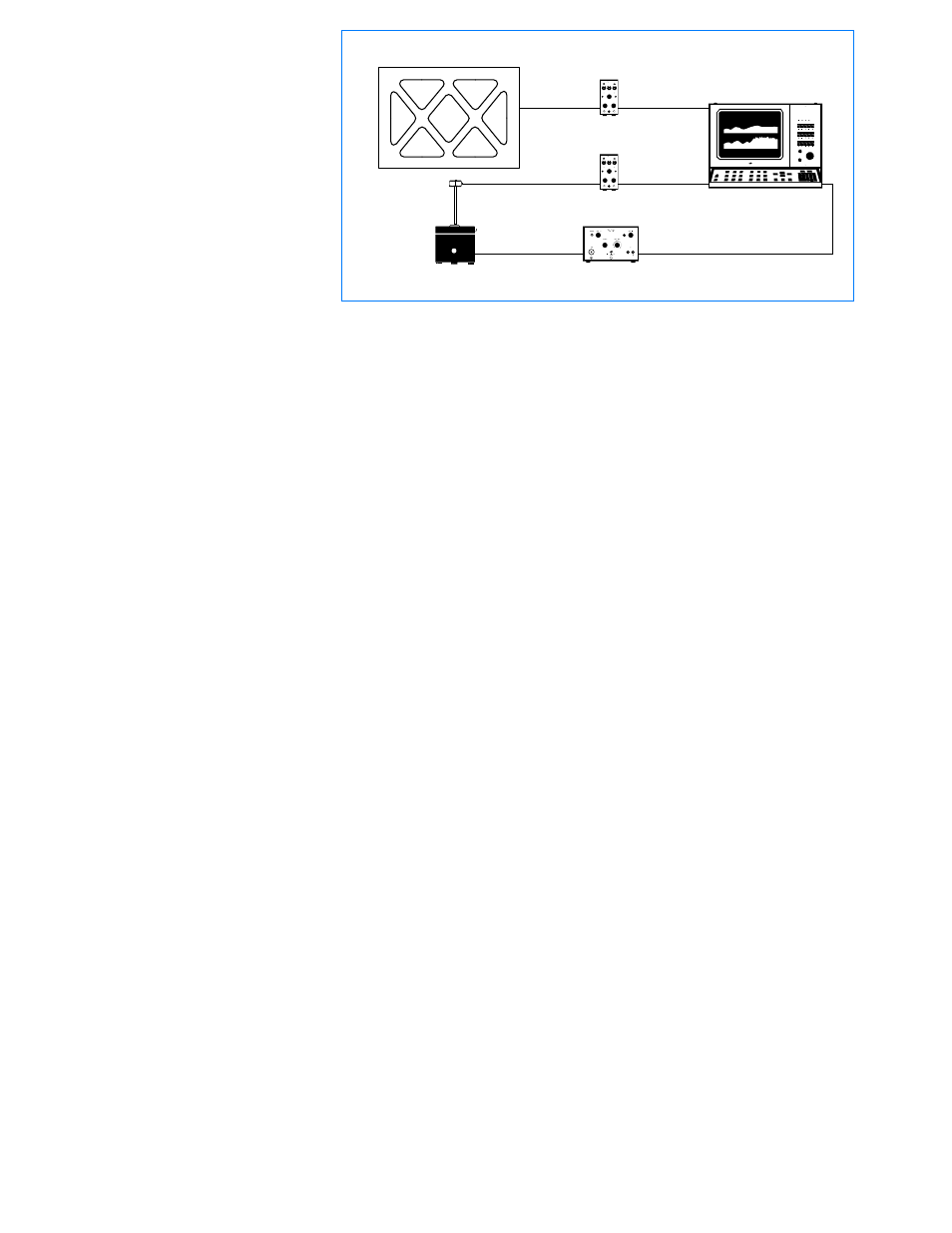

Example of set-up, Fig.2 typical frequency response test set-up – Atec Bruel-Kajaer-2706 User Manual

Page 2

2

variable gain control and a preampli-

fier. The preamplifier is capacitively

coupled to the driver stage, which is

equipped with a clipping detector. Ex-

cessive signal levels at the input will

saturate the amplifier and cause clip-

ping of the output waveform. This

will trigger the clipping detector,

which then lights the yellow clipping

warning light on the front panel. The

instrument remains in operation dur-

ing clipping.

The power stage employs an output

current limiter, which limits the in-

stantaneous positive and negative

peaks of the output current. The pow-

er output stage is protected by a tem-

perature sensing device. Abnormal

load conditions, high ambient tem-

peratures or an output short-circuit

could result in output transistor tem-

peratures well in excess of design

limits. To prevent any subsequent

damage, the temperature protective

circuitry blocks the amplifier input

signal. When the heat-sink tempera-

ture reverts to the normal level the

power amplifier will automaticially

regain operation.

Example Of Set-Up

A typical frequency response test set-

up for vibration testing is shown in

Fig. 2.

An input forcing signal is taken

directly from the Signal Analyzer

Type 2032 and is fed to the power

amplifier which drives the Vibration

Exciter Type 4809. The signal ana-

lyzer measures the input forcing sig-

nal and the structural response

signal and uses them to produce a

representation of frequency response

function of the structure under test.

Power Amplifier

2706

Dual Channel Signal

2032

Charge Amplifier

2635

Charge Amplifier

2635

Accelerometer

4384

Force Transducer

8200

850792/1e

Fig.2 Typical frequency response test set-up