Atec Edwards-300E User Manual

Page 2

DOUBLE PUMP SYSTEM

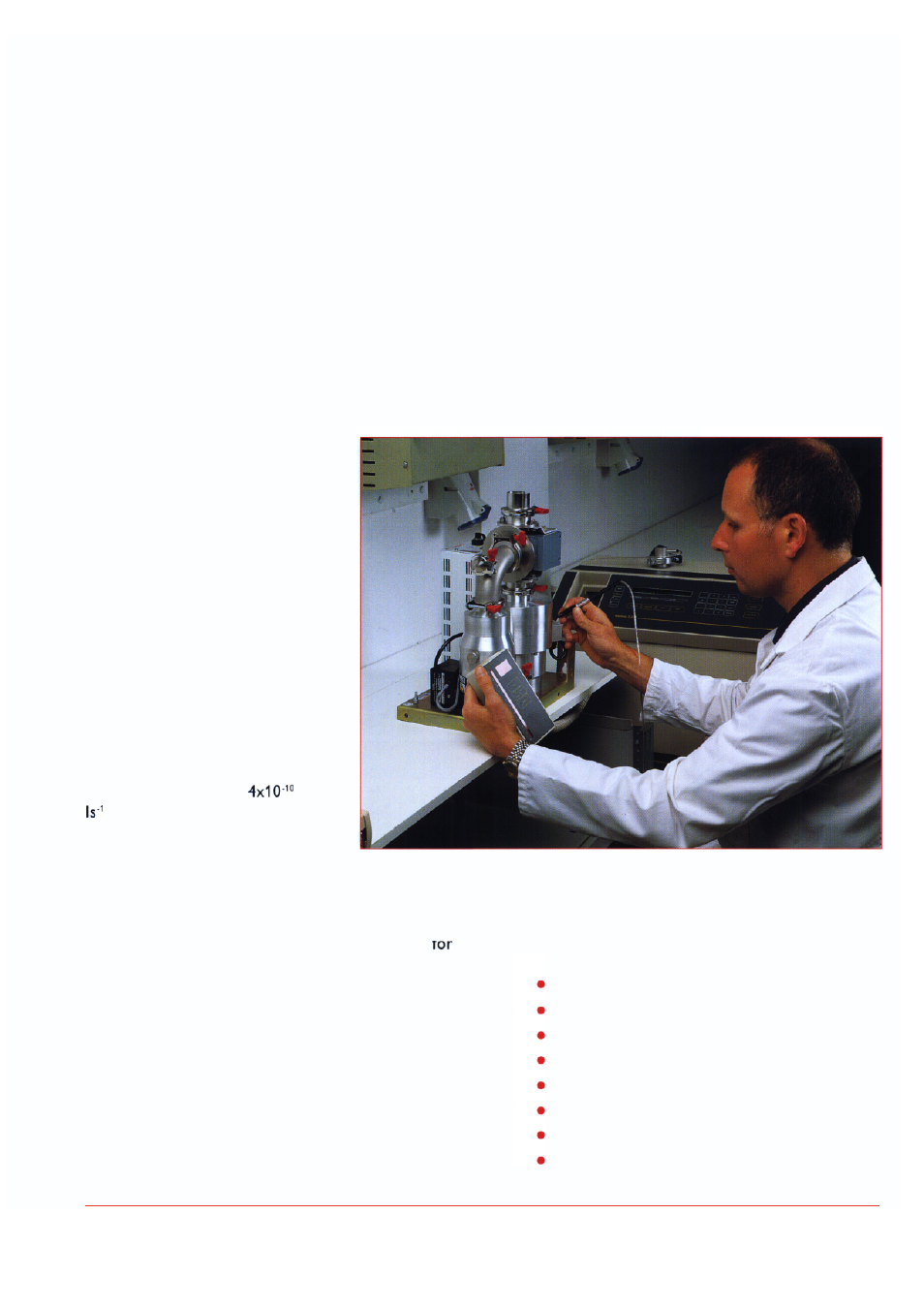

PORTABILITY

The Spectron 300E employs a unique double diffusion

pump system for high performance combined with

rugged reliability. One of the Edwards E040 air

cooled diffusion pumps continuously pumps the mass

spectrometer head via a special restrictor. The other

pumps the test piece. The high compression ratio

acheived gives a fast response and a very fast clean-up

time unaffected by helium in the backing line. In

addition the sensitivity of the Spectron 300E is

independent of the size of backing pump used.

PROCESS CONTROL MODULE

The system is simple to use at any

desired level of control, with keylock

facilities to prevent tampering, which

is particularly important for a

portable instrument.

The unit has an alpha-numeric LED

display for clear viewing at a distance

and there is a standard recorder

output to enable a permanent record

to be made.

UNPARALLELED RANGE

The Edwards 300E is a complete unit

which gives the best specification

without having to buy extras.

The massive, gross and fine test

modes, all built into the unit, cover a

range of atmosphere to

mbar

and the maximum intake pressure

is one atmosphere. The minimum

detectable leak rate is unaffected by

the size of the backing pump. Clean-

up time and stability are superior to

other units.

The Spectron 300E is a strong rugged leak detector

designed to operate in dirty industrial conditions as

well as the clean research areas.

Spectron 300E features fold down carrying handles

but for those applications where the unit is likely to

be in demand over a large site a specially designed

trolley accessory is available. The trolley runs easily

on large go anywhere wheels and features a handy

lockable storage space for instruments, accessories

and tools.

Typical applications for the Spectron 300E will be

I

II r

found at:-

A larger roughing pump can be fitted to tne trolley

rapid evacuation of larger volumes. Alternatively, the

pump can be bench mounted and connected via a side

port on the leak detector. This will not affect the

sensitivity.

Industrial coating equipment sites

Chemical and power plants

Vacuum furnace installations

High energy physics establishments

Space simulation laboratories

Metallurgy installations

Refrigeration installations

Any type of industrial vacuum system

- eg freeze dryers