Est), Uropean, Tandards – Atec Elgar-est User Manual

Page 2: Ester, Pa 1000, Ordering information

Elgar

■

1.800.733.5427

■

858.450.0085

■

Fax 858.458.0267

■

9250 Brown Deer Road, San Diego, CA 92121

■

www.elgar.com

■

email: [email protected]

17

E

UROPEAN

S

TANDARDS

T

ESTER

(EST)

PA 1000

Unique among analyzer systems, the EST

Series PA 1000 performs all measurements

and real-time digital signal processing. The

PC is only used to display the User

Interface which provides control of the

equipment. Other key features of the

analyzer are:

■

Sampling rate of 175,000 samples/s

■

18 bit A-to-D converters

■

24 bit/80 MIPS real-time DSP

■

Optional Discrete Reference

Impedance

■

No range switching required to

measure the full 16 amp range

■

Continuous AC power source

monitoring

■

Front or rear panel EUT power

connections

■

Flickermeter complies with EN 868

and EN 61000-4-15

■

1 year calibration interval

The PA 1000 offers full compliance with

on-board, self contained, computation.

The PA 1000 digital signal processor

performs all computations including

filtering, weighing, FFT’s and DFT’s.

SET-UP

Simple start-up windows provide easy test

set-up fields and EST system control. Each

test configuration can be rerun from the

test template screen and is stored as part

of a test log history file. Class selection

includes A, B, C and D and an auto A/D

feature that enables the analyzer to classify

the equipment during the test. All data is

exportable to spreadsheet applications.

HARMONICS (EN 61000-3-2)

The harmonics graphs and tables are

updated continuously during the test. The

harmonic bar chart displays the harmonic

content of the EUT as well as displaying

the limit for each harmonic specified by the

standard. Absolute and relative harmonic

measurements can be displayed

simultaneously. Worst case measurements

are stored throughout the test and

displayed with pass/fail designation.

The PA 1000 meets

t

he exact requirements

of the EN 61000-3-2, as described in

Annex B.4.2.

Annex B.4.2

Additional requirements for all other

cases, including fluctuating harmonics

a) There shall be no gap, and no overlapping between

successive measuring windows for rectangular

(“uniform”) windows.

FLICKER (EN 61000-3-3)

Pt plot displays the distribution of

instantaneous flicker values. An

innovative dt distribution graph assists

the user in troubleshooting the equipment

under test. This plot displays the

distribution of voltage deviations.

IMMUNITY TESTING

The EST’s AC source generates waveforms

compliant with the following immunity test

standards:

EN 61000-4-11 Voltage Dips, Short

Interruptions and Voltage

Variations (Pre-Compliance)

EN 61000-4-13 Harmonics, Interharmonics

including Mains Signaling

at AC Powerport –

Immunity Test

EN 61000-4-14 Voltage Fluctuation –

Immunity Test

EN 61000-4-17 Ripple on DC Input Power

Port – Immunity Test

EN 61000-4-28Variation of the Power

Frequency - Immunity Test

The EST’s User Interface includes test

routines for each of these immunity tests.

The tests can be executed following a

simple wizard format. All test parameters

can be changed. During all immunity tests

three charts are plotted continually (plot

points updated every 1.5 seconds, user

adjustable) for frequency, VRMS and IRMS.

The short form report contains pass/fail,

calibration data and test configuration (the

minimum information typically required by

regulatory agencies).

Sampling data is provided for harmonics

and flicker, worst case values, and other

data that is useful for troubleshooting and

maintaining historical records for

equipment designers.

IMMUNITY TEST REPORTS

Reports are also generated for the

immunity tests. After each test sequence is

run a note pad screen is automatically

generated. This note pad stores the

operator’s comments and observations for

each sequence. These notes are

automatically logged in the test report in

the test and sequence order. Reports also

contain all test configuration data fields.

Reports and all test data may be down-

loaded for spreadsheet applications for

maximum user versatility.

Note: For more information on the SWAE see page 15.

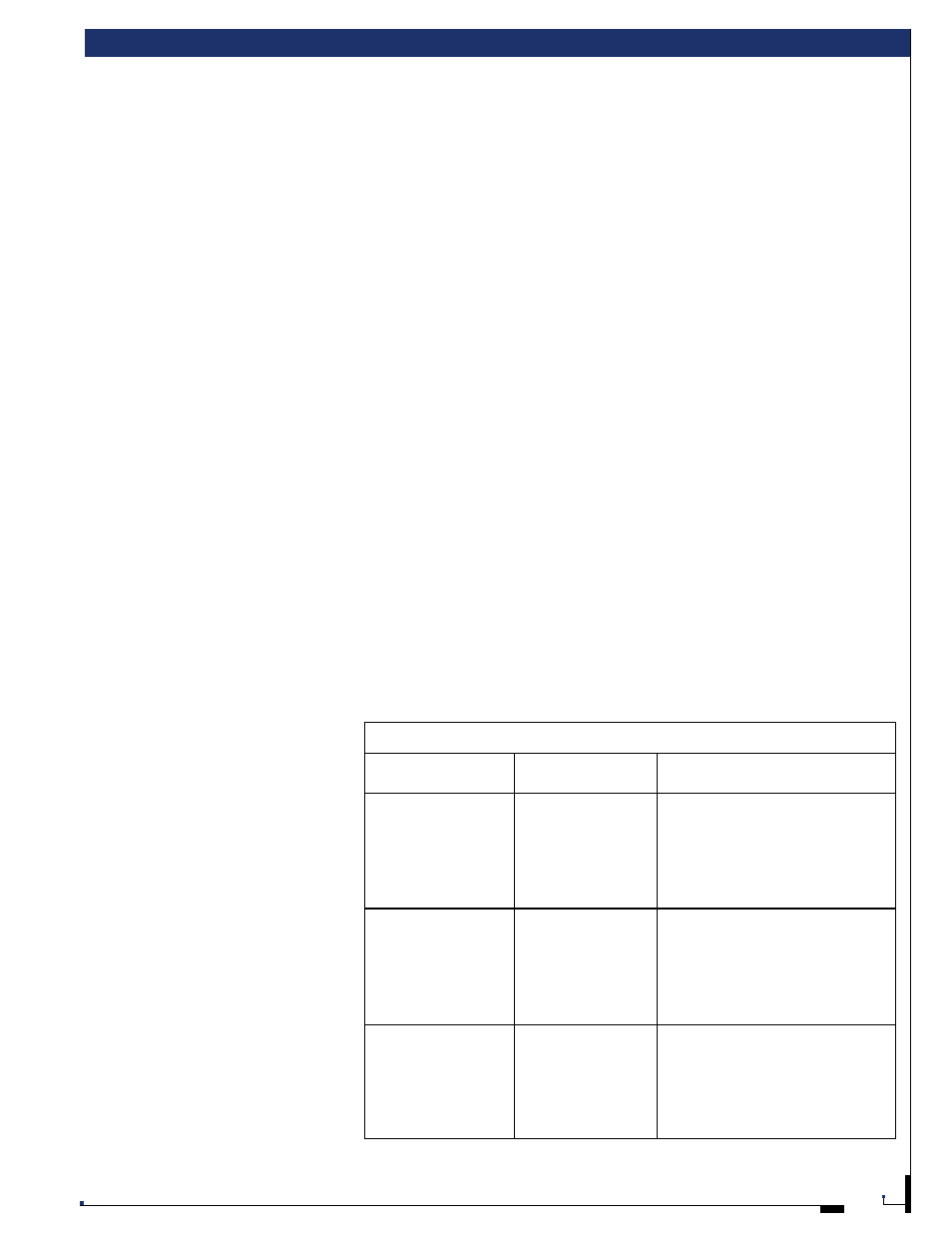

Ordering Information

Model

Output Power

AC Input

Rating

EST 1750-1

1750 VA

1

187-264 VRMS (L-L), 3 wire

EST 1750-2

1750 VA

1

342-457 VRMS (L-L), 4 wire

EST 1750-3*

1750 VA

1

187-264 VRMS (L-L), 3 wire

EST 1750-4*

1750 VA

1

342-457 VRMS (L-L), 4 wire

230 V L-N, Single Phase, 3 wire

EST 3700-1

3700 VA

2

187-264 VRMS (L-L), 3 wire

EST 3700-2

3700 VA

2

342-457 VRMS (L-L), 4 wire

EST 3700-3*

3700 VA

2

187-264 VRMS (L-L), 3 wire

EST 3700-4*

3700 VA

2

342-457 VRMS (L-L), 4 wire

230 V L-N, Single Phase, 3 wire

EST 5250-1

5250 VA

3

187-264 VRMS (L-L), 3 wire

EST 5250-2

5250 VA

3

342-457 VRMS (L-L), 4 wire

EST 5250-3*

5250 VA

3

187-264 VRMS (L-L), 3 wire

EST 5250-4*

5250 VA

3

342-457 VRMS (L-L), 4 wire

230 V L-N, Single Phase, 3 wire

* Power factor corrected

1

1495 VA at 230V output

2

3680 VA at 230V output

3

4485 VA at 230V output

Any model can be ordered with the optional discrete reference impedance in addition to the standard synthesized impedance.